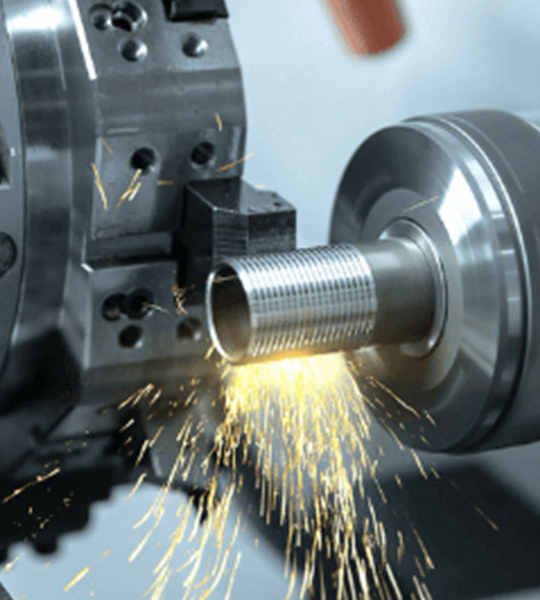

Product Description

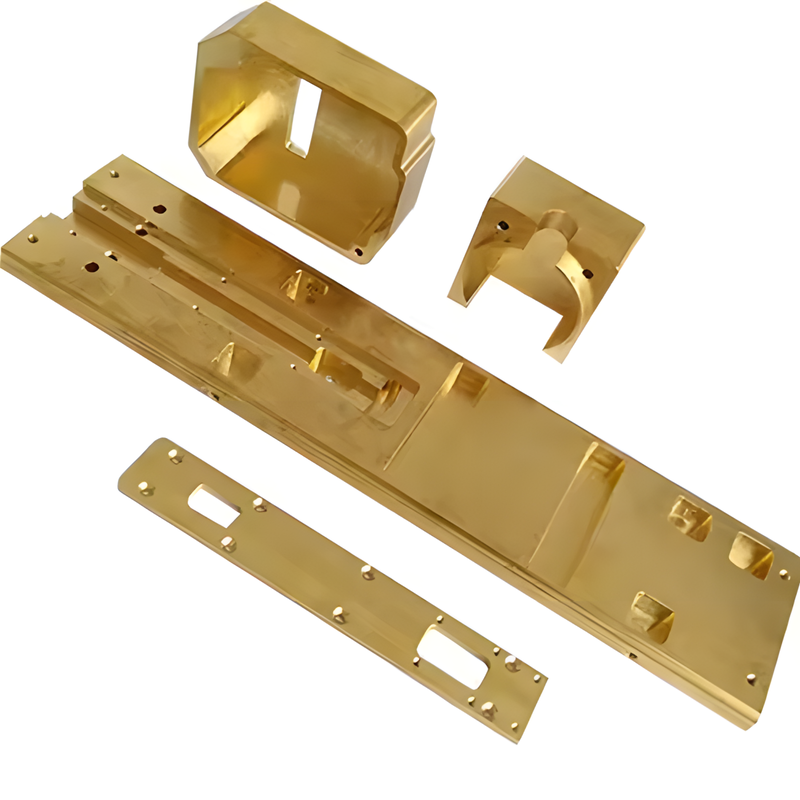

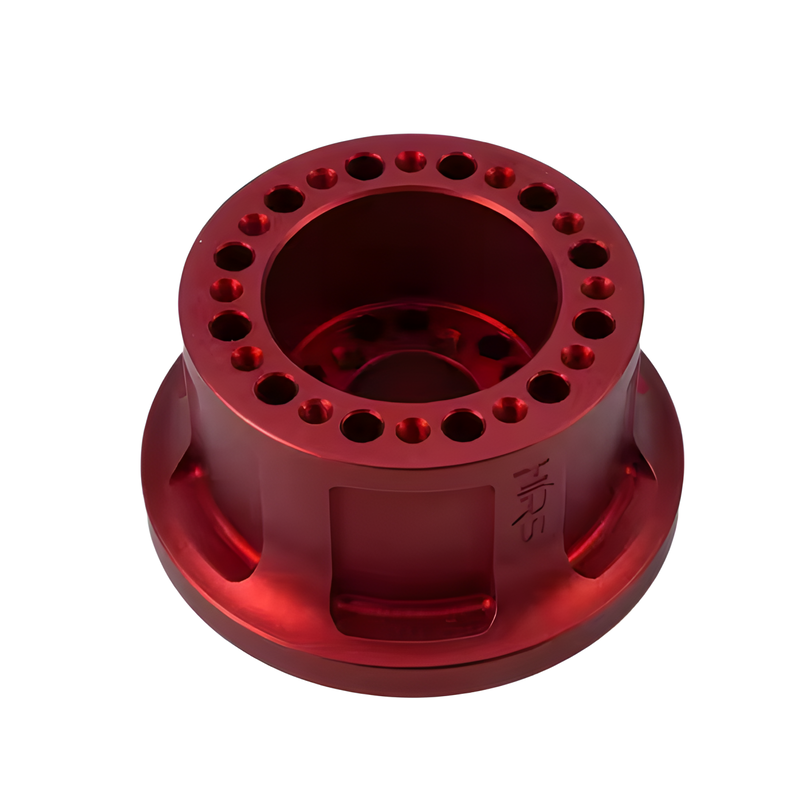

Fabrication High Precision Brass Parts for Accessories are custom-machined components made from high-quality brass. Designed for durability and corrosion resistance, they are ideal for decorative and functional use. Precision CNC machining ensures tight tolerances and fine finishes. Commonly used in electronics, plumbing, and mechanical assemblies. Available in various shapes and sizes to meet specific design needs.

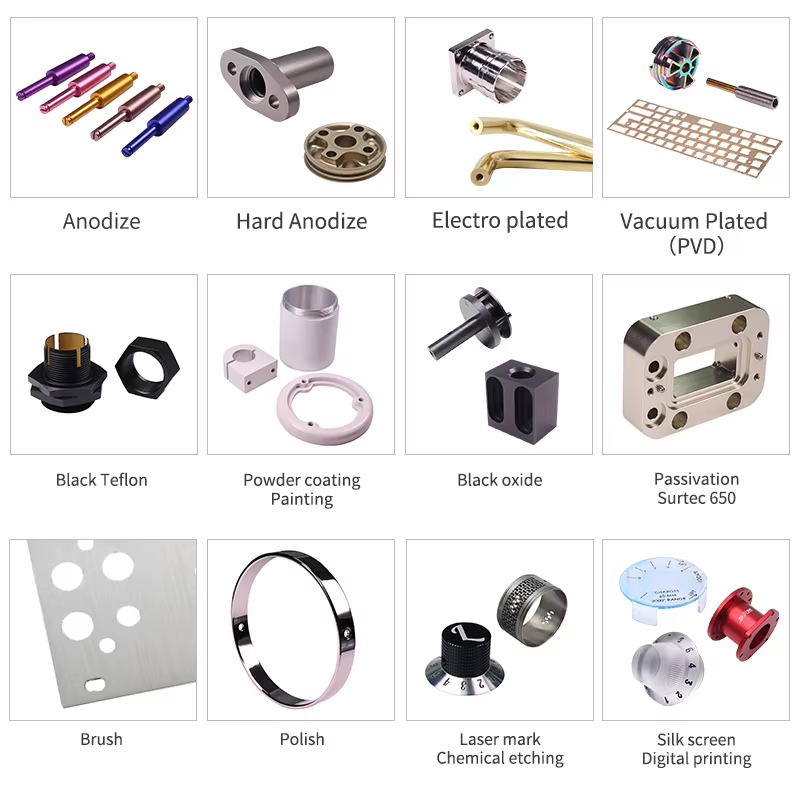

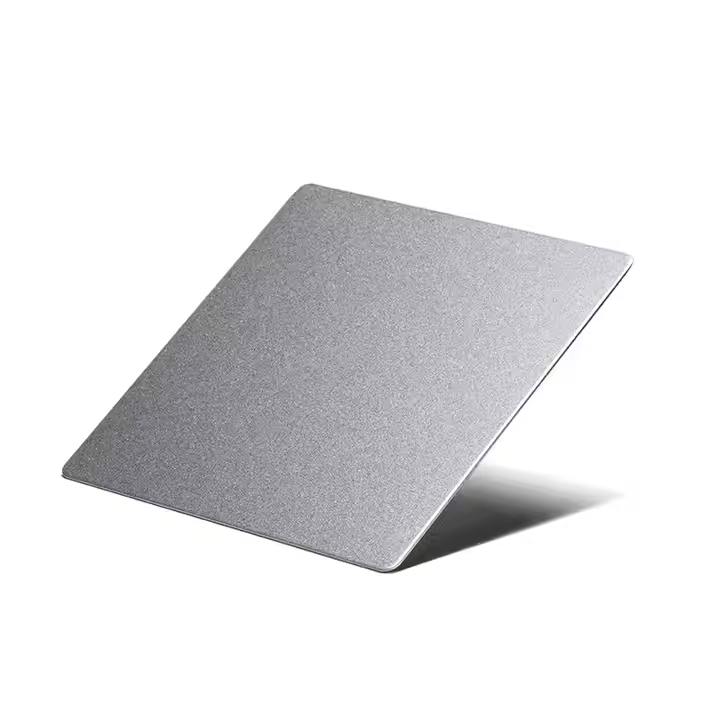

Surface Treatment

Surface treatments include polishing, electroplating (nickel, chrome, or gold), and sandblasting for enhanced appearance and durability. Anti-oxidation coatings are applied to prevent tarnishing. Custom finishes are available based on application requirements.

Product parameters

| Process | CNC turning, cnc milling, cnc machining,deburr, anodizing, electroplating,etc. |

| Material | Aluminum, brass, stainless steel, steel, titanium alloy,etc. |

| Tolerance | + / -0.005, +/-0.1mm |

| Roughness | Ra 0.4~1.6 or N7 |

| Finished | As requirement. Anodizing, hard anodizing, electroplating,etc. |

| Logo / mark | Can be customized. Laser engraving |

| Application | Auto parts, Sensor industry, Fluid system, Automation equipment, motorcycle etc. |

| Certification | ISO 9001 certification |

| Inspection | 100% inspection before delivery |

Custom Process

Upload your design

Design analysis

Start production

Receive your parts

Process Type

Milling & Drilling

CNC Machining

Laser Cutting

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

Quality control ensures each brass part meets precise dimensional and visual standards. Inspections are conducted using calipers, micrometers, and vision systems. Surface finish and plating quality are thoroughly checked. Tolerances are maintained within specified limits for high performance. Each production batch undergoes random sampling and testing. All processes comply with ISO 9001:2015 quality management standards.

Processing capability