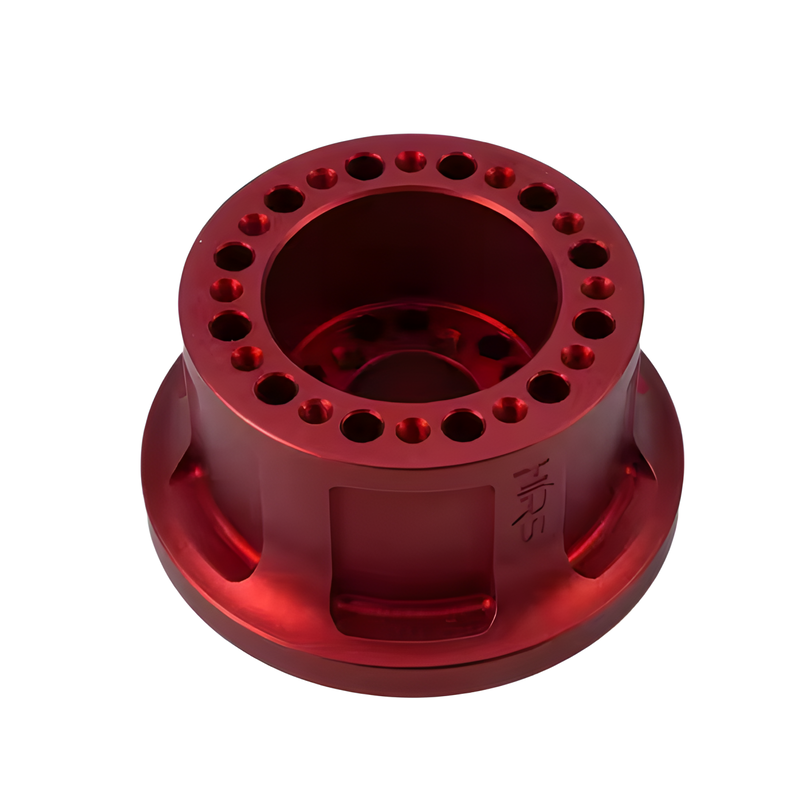

Product Description

High-precision CNC machined parts designed for robotic and mechanical arms. Made from durable metals like aluminum, stainless steel, and steel alloys. Supports complex geometries with tight tolerances up to ±0.02 mm. Processes include milling, turning, drilling, laser cutting, and wire EDM. Custom surface treatments available: anodizing, plating, and more. Ideal for automation, robotics, industrial machinery, and prototyping. Fully customizable to match customer drawings or 3D models. Prototyping and low-volume production supported. Strict quality control with full inspection of critical dimensions. Reliable performance for both static and dynamic applications.

Product parameters

| Brand Name | Custom Precision CNC Machining Mechanical Arm Parts |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Stainless Steel, Steel Alloys, Other |

| Type | DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM |

| Model Number | Machine Arm |

| Accuracy | +/-0.02 |

| Process | CNC milling |

| Surface Treatment | Can do anodizing or plating |

| Prototype | support prototype and small quantity |

| Quality Control | full inspection of cractical dimensions |

Custom Process

Upload your design

Design analysis

Start production

Receive your parts

Process Type

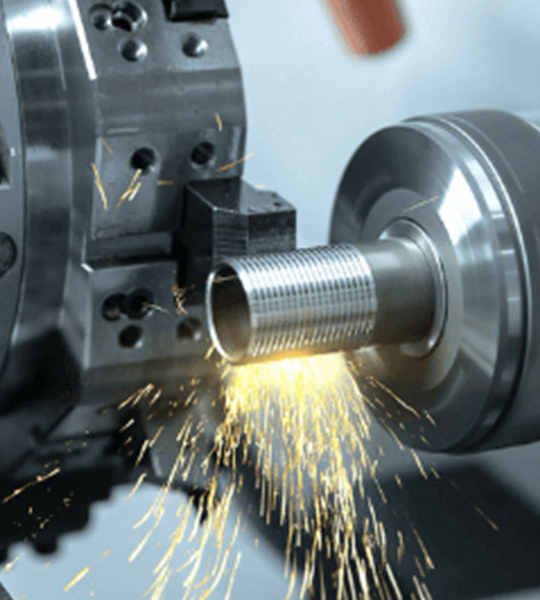

Milling & Drilling

CNC Machining

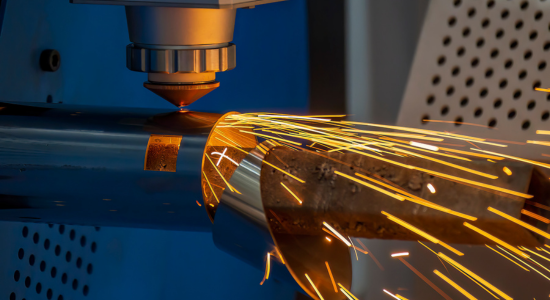

Laser Cutting

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

100% inspection of all critical dimensions with precision measuring tools.

Use of CMM, micrometers, calipers, and height gauges for accuracy.

In-process checks at multiple stages to maintain tolerance consistency.

Final inspection before packaging and delivery to eliminate defects.

Material traceability and certification available upon request.

Surface finish, flatness, and thread checks per customer specifications.

FAI (First Article Inspection) and PPAP documentation support.

Inspection reports provided for each batch or custom request.

Continuous quality improvement through feedback and analysis.

Processing capability

Supports a wide range of materials: aluminum, stainless steel, brass, and more.

Capabilities include milling, turning, drilling, laser cutting, and wire EDM.

Tolerances as tight as ±0.02 mm for high-precision parts.

Custom machining solutions based on detailed customer drawings or CAD models.

Flexible production from single prototypes to small and large batches.

Rapid prototyping and quick turnaround for time-sensitive projects.

Capability to handle both static and dynamic mechanical arm components.

Surface treatments available, including anodizing and plating for durability.

Comprehensive CAD/CAM integration for optimized machining processes.