Product Description

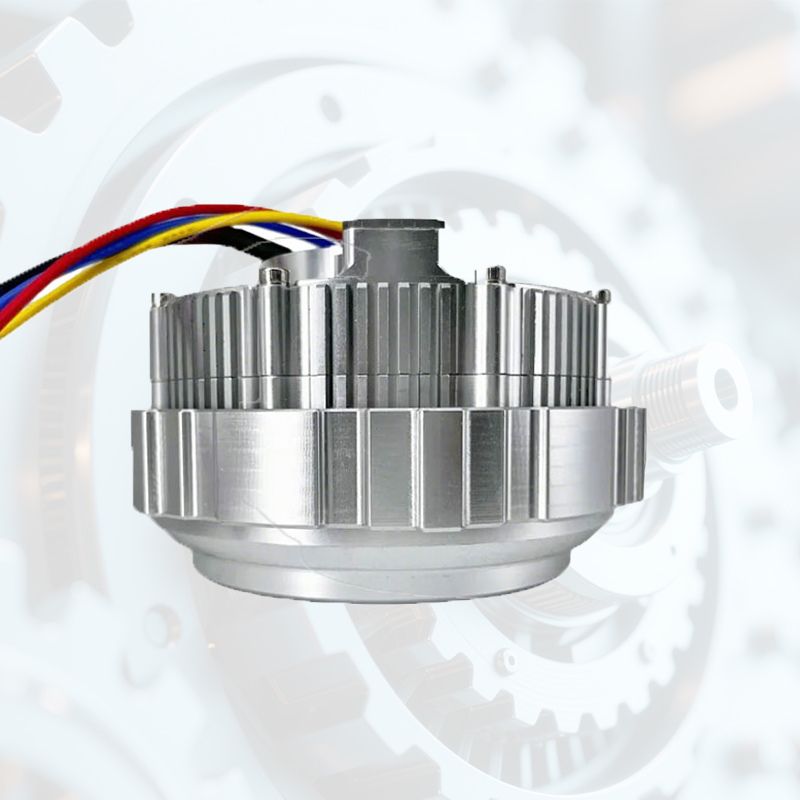

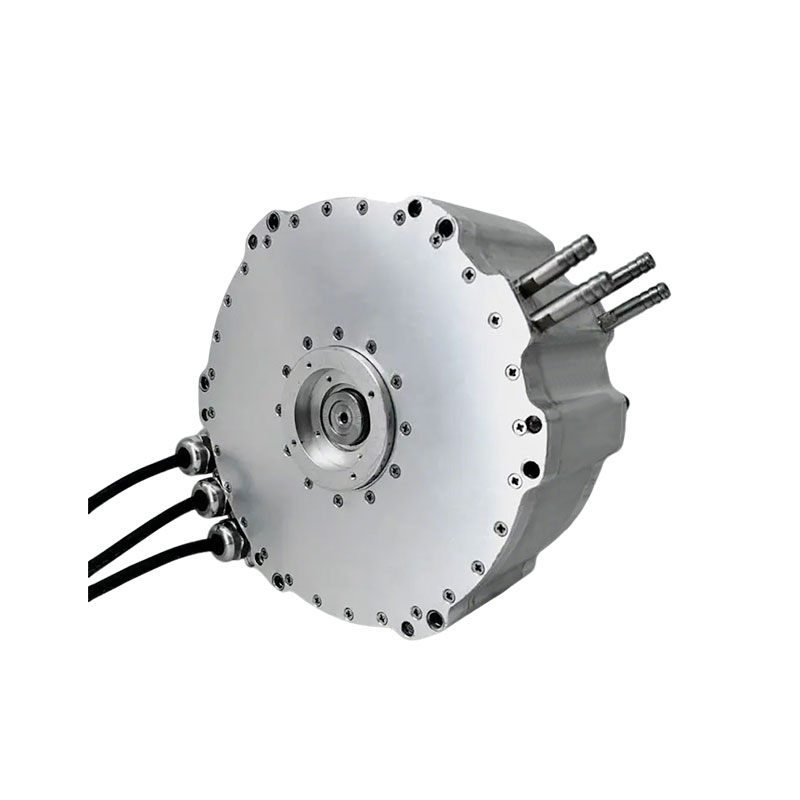

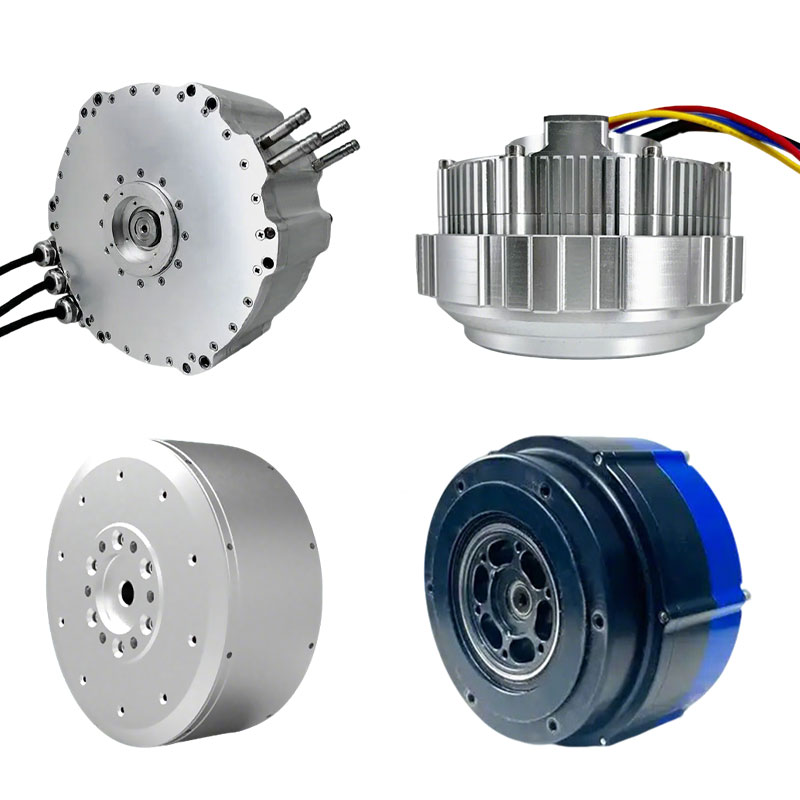

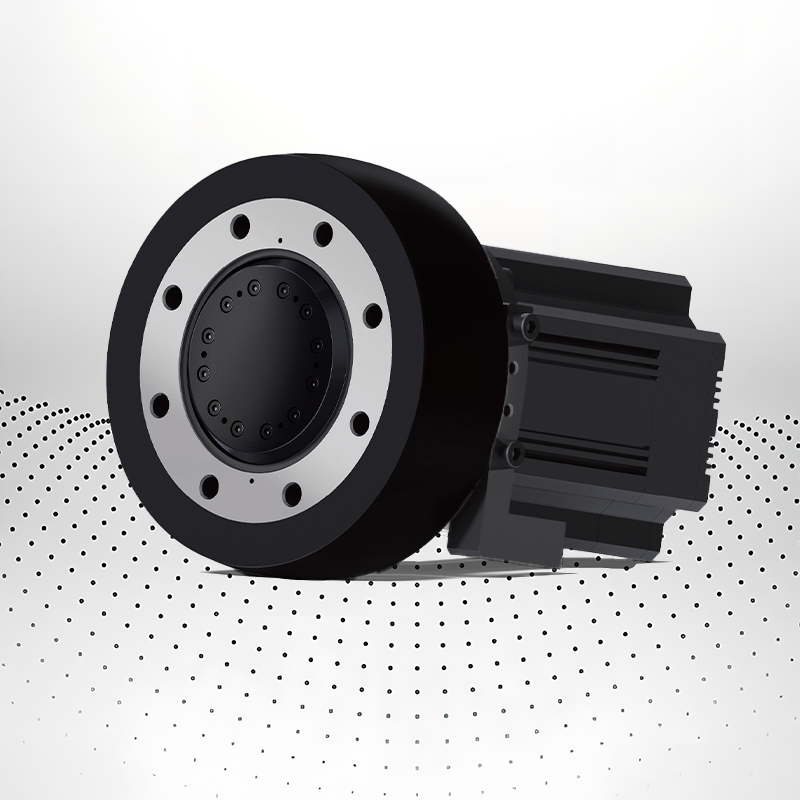

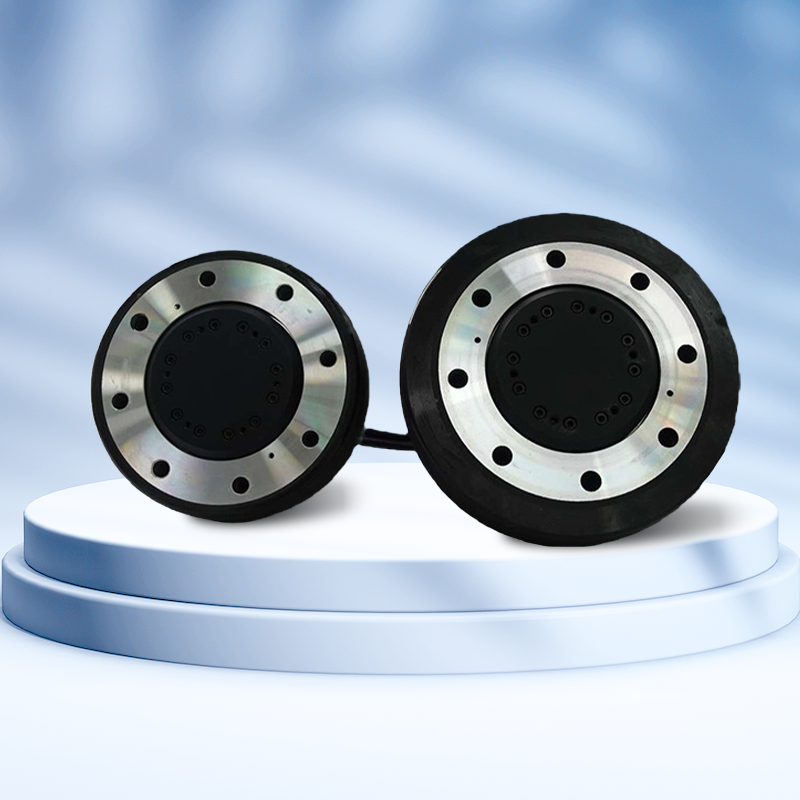

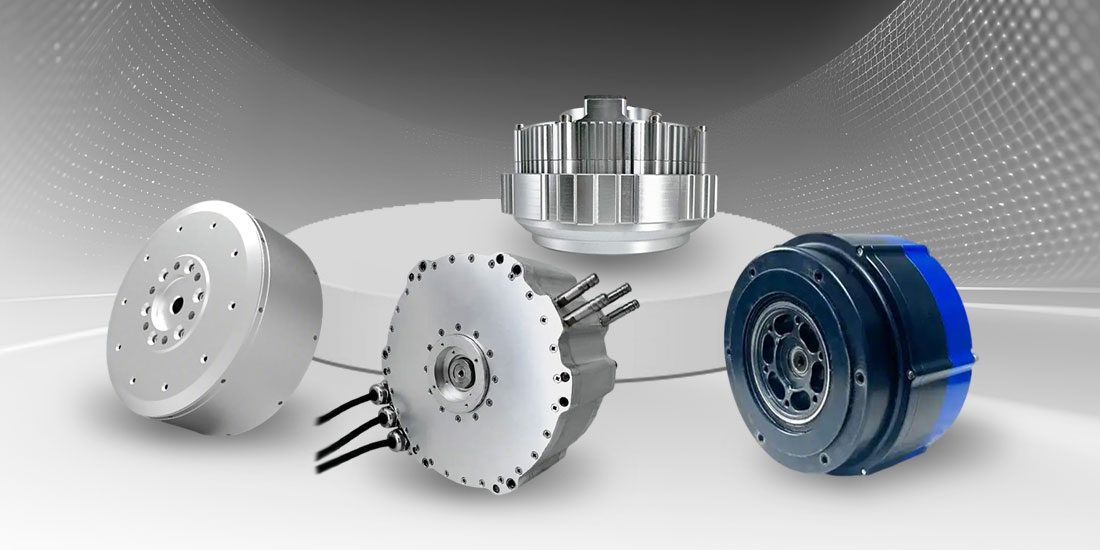

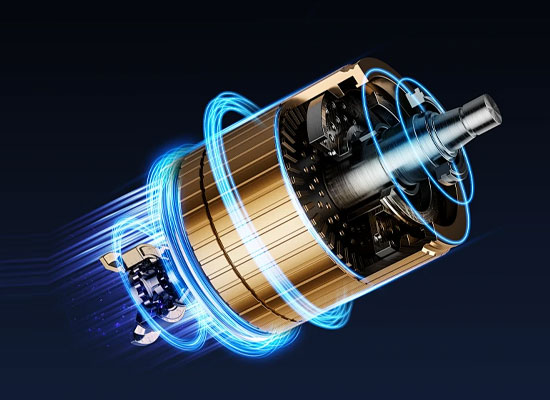

The hub motor series is a lightweight and high-torque articulated motor specially designed for wheeled robots. It integrates energy-focused magneto-motors, precision planetary reducers, and high-precision encoders. With a compact structure, it can save installation space and is particularly suitable for wheeled robots. Meanwhile, the company supports customized services for different installation structures.

Functional Features

Precision manufacturing

Advanced manufacturing processes are adopted to ensure the accuracy

and durability of the motor and enhance the overall quality

Low-noise design

Optimize the structural design to effectively reduce operating noise and provide a comfortable usage environment

Energy saving and high efficiency

High energy efficiency ratio design reduces energy consumption

and is more economical and environmentally friendly for long-term use

Product parameters

SETZ70 series hub motor parameter information table (external driver version) | |||||||||||||||

Model number | Output parameter | Reduction ratio | Machine plus custom case version -J | Mould case plate -G | |||||||||||

Bus voltage (Vdc) | Rated power (kW) | Peak power (kW) | Rated speed (rpm) | Maximum speed (rpm) | Rated torque (Nm) | Peak torque (Nm) | Rated current (Arms) | Peak current (Arms) | Overall dimension | Weight (kg) | Overall dimension | Weight (kg) | |||

Advanced edition | SETZ70-1IA | 48 | 0.2 | 0.7 | 1600 | 2800 | 0.75 | 6.5 | 3.9 | 40 | 1 | φ78*42 | 0.55 | / | / |

SETZ70-1IB | 0.3 | 1.25 | 2250 | 4000 | 7 | 5.4 | 60 | ||||||||

SETZ70-1JA | 0.2 | 0.7 | 400 | 700 | 3 | 26 | 3.9 | 40 | 4 | φ78*55 | 0.65 | / | / | ||

SETZ70-1JB | 0.3 | 1.25 | 562.5 | 1000 | 28 | 5.4 | 60 | ||||||||

SETZ70-1KA | 0.2 | 0.7 | 177 | 311 | 6.75 | 58.5 | 3.9 | 40 | 9 | φ78*65 | 0.75 | / | / | ||

SETZ70-1KB | 0.3 | 1.25 | 250 | 444 | 63 | 5.4 | 60 | ||||||||

SETZ70-1LA | 0.2 | 0.7 | 100 | 175 | 12 | 104 | 3.9 | 40 | 16 | 0.85 | / | / | |||

SETZ70-1LB | 0.3 | 1.25 | 140 | 250 | 112 | 5.4 | 60 | ||||||||

SETZ70-1MA | 0.2 | 0.7 | 66.5 | 116.5 | 18 | 156 | 3.9 | 40 | 24 | φ78*67 | 0.95 | / | / | ||

SETZ70-1MB | 0.3 | 1.25 | 93.5 | 166.5 | 168 | 5.4 | 60 | ||||||||

SETZ70-1NA | 0.2 | 0.7 | 45.5 | 80 | 26.25 | 227.5 | 3.9 | 40 | 35 | φ78*85 | 1.1 | / | / | ||

SETZ70-1NB | 0.3 | 1.25 | 64 | 114 | 245 | 5.4 | 60 | ||||||||

1. The peak torque duration in the table is less than 1s; The weight and volume of different fixing methods are slightly different, more parameter information please contact the company's technical personnel; | |||||||||||||||

SETZ90 series wheel hub motor parameter information table | |||||||||||||||

Model number | Output parameter | Reduction ratio | Machine plus custom case version -J | Mould case plate -G | |||||||||||

Bus voltage (Vdc) | Rated power (kW) | Peak power (kW) | Rated speed (rpm) | Maximum speed (rpm) | Rated torque (Nm) | Peak torque (Nm) | Rated current (Arms) | Peak current (Arms) | Overall dimension | Weight (kg) | Overall dimension | Weight (kg) | |||

Advanced edition | SETZ90-1DA | 48 | 0.25 | 1.05 | 1600 | 2600 | 1.5 | 12 | 9.6 | 75 | 1 | φ99*57 | 1.1 | φ100*57 | 1.15 |

SETZ90-1DB | 320 | 520 | 7.5 | 60 | 5 | 1.25 | 1.3 | ||||||||

SETZ90-1DE | 200 | 325 | 12 | 96 | 8 | φ99*80 | 1.4 | φ100*80 | 1.5 | ||||||

SETZ90-1DC | 160 | 260 | 15 | 120 | 10 | ||||||||||

SETZ90-1DD | 100 | 162.5 | 24 | 192 | 16 | ||||||||||

SETZ90-1DF | 89 | 144.5 | 27 | 216 | 18 | φ99*83 | 1.5 | φ100*83 | 1.6 | ||||||

SETZ90-1DH | 76 | 123.5 | 31.5 | 252 | 21 | φ99*85 | 1.6 | φ100*85 | 1.7 | ||||||

SETZ90-1DG | 53 | 86.5 | 45 | 360 | 30 | 1.7 | 1.8 | ||||||||

Parameter Remarks: The peak torque duration in the table is less than 1s; The weight and volume of different fixing methods are slightly different, more parameter information please contact the company's technical personnel; | |||||||||||||||

SETZ120 series wheel hub motor parameter information table | |||||||||||||||

Model number | Output parameter | Reduction ratio | Machine plus custom case version -J | Mould case plate -G | |||||||||||

Bus voltage (Vdc) | Rated power (kW) | Peak power (kW) | Rated speed (rpm) | Maximum speed (rpm) | Rated torque (Nm) | Peak torque (Nm) | Rated current (Arms) | Peak current (Arms) | Overall dimension | Weight (kg) | Overall dimension | Weight (kg) | |||

Advanced edition | SETZ120-1AC | 48 | 0.25 | 1.15 | 1000 | 1500 | 2.5 | 21.5 | 7.3 | 65 | 1 | φ128*70 | 1.6 | φ130*70 | 1.8 |

SETZ120-1AD | 0.4 | 2 | 1550 | 2200 | 22 | 10 | 100 | ||||||||

SETZ120-1BC | 0.25 | 1.15 | 125 | 187.5 | 20 | 172 | 7.3 | 65 | 8 | 2.1 | 2.3 | ||||

SETZ120-1BD | 0.4 | 2 | 193.5 | 275 | 176 | 10 | 100 | ||||||||

SETZ120-1CC | 0.25 | 1.15 | 100 | 150 | 25 | 215 | 7.3 | 65 | 10 | φ128*95 | 2.4 | φ130*95 | 2.7 | ||

SETZ120-1CD | 0.4 | 2 | 155 | 220 | 220 | 10 | 100 | ||||||||

SETZ120-1DC | 0.25 | 1.15 | 62.5 | 93.5 | 40 | 344 | 7.3 | 65 | 16 | 2.6 | 2.9 | ||||

SETZ120-1DD | 0.4 | 2 | 96.5 | 137.5 | 352 | 10 | 100 | ||||||||

SETZ120-1RC | 0.25 | 1.15 | 55.5 | 83 | 45 | 387 | 7.3 | 65 | 18 | φ128*100 | 2.7 | φ130*100 | 3 | ||

SETZ120-1RD | 0.4 | 2 | 86 | 122 | 396 | 10 | 100 | ||||||||

SETZ120-1EC | 0.25 | 1.15 | 47.5 | 71.5 | 52.5 | 451.5 | 7.3 | 65 | 21 | 2.8 | 3.1 | ||||

SETZ120-1ED | 0.4 | 2 | 73.5 | 104.5 | 462 | 10 | 100 | ||||||||

SETZ120-1MC | 0.25 | 1.15 | 38.5 | 57.5 | 65 | 559 | 7.3 | 65 | 26 | 3 | 3.3 | ||||

SETZ120-1MD | 0.4 | 2 | 59.5 | 84.5 | 572 | 10 | 100 | ||||||||

SETZ120-1NC | 0.25 | 1.15 | 28.5 | 42.5 | 87.5 | 752.5 | 7.3 | 65 | 35 | φ128*105 | 3.2 | φ130*105 | 3.5 | ||

SETZ120-1ND | 0.4 | 2 | 44.5 | 62.5 | 770 | 10 | 100 | ||||||||

SETZ120-1OC | 0.25 | 1.15 | 14 | 21 | 175 | 1505 | 7.3 | 65 | 70 | φ128*115 | 4.4 | φ130*115 | 4.7 | ||

SETZ120-1OD | 0.4 | 2 | 22 | 31 | 1540 | 10 | 100 | ||||||||

Parameter Remarks: The peak torque duration in the table is less than 1s; The weight and volume of different fixing methods are slightly different, more parameter information please contact the company's technical personnel; | |||||||||||||||

SETZ special series wheel motor parameter information table | |||||||||||||||

Model number | Output parameter | Reduction ratio | Machine plus custom case version -J | Mould case plate -G | |||||||||||

Bus voltage (Vdc) | Rated power (kW) | Peak power (kW) | Rated speed (rpm) | Maximum speed (rpm) | Rated torque (Nm) | Peak torque (Nm) | Rated current (Arms) | Peak current (Arms) | Overall dimension | Weight (kg) | Overall dimension | Weight (kg) | |||

Basic edition | SETZ150-5BA | 48 | 0.7 | 5 | 1500 | 2000 | 4.5 | 35 | 15 | 150 | 1 | φ165*75 | 2.5 | / | / |

SETZ150-5BB | 93.5 | 125 | 72 | 560 | 16 | φ165*105 | 4.5 | / | / | ||||||

SETZ150-5BC | 55.5 | 74 | 121.5 | 945 | 27 | φ165*115 | 5 | / | / | ||||||

SETZ150-5BD | 50 | 66.5 | 135 | 1050 | 30 | φ165*115 | 5 | / | / | ||||||

SETZ160-4CA | 48 | 1.35 | 4 | 1500 | 1800 | 9 | 45 | 30 | 180 | 1 | φ180*90 | 4.5 | / | / | |

SETZ160-4CB | 150 | 180 | 90 | 450 | 10 | φ180*125 | 6.5 | / | / | ||||||

SETZ220-11BA | 96 | 1.55 | 11 | 1000 | 1800 | 15 | 80 | 30 | 160 | 1 | φ220*100 | 7.5 | / | / | |

SETZ220-11BB | 66.5 | 120 | 225 | 1200 | 15 | φ220*155 | 11.5 | / | / | ||||||

SETZ220-11BC | 50 | 90 | 300 | 1600 | 20 | φ220*165 | 15 | / | / | ||||||

Note: The peak torque duration in the table is less than 1s, the weight and volume of different fixing methods are slightly different, more parameter information please contact the company's technical personnel; | |||||||||||||||

Application

Hub motors are widely used. In the application of special robots, their high integration simplifies the mechanical structure, enabling the robot to flexibly adapt to complex and narrow Spaces. In the field of new energy vehicles, hub motors can precisely control torque vectoring, independently adjust the power of each wheel, optimize the vehicle's acceleration, braking and steering performance, increase the range, and also free up more space inside the vehicle. After installing hub motors on electric motorcycles, the center of gravity of the entire vehicle is lowered, and the response is rapid, making it easier for riders to control.

In the field of electric ships, hub motors assist vessels in achieving complex operations such as in-place steering and precise docking, enhancing maneuverability and operational efficiency, and reducing maintenance costs. Electric aircraft and unmanned aerial vehicles increase payload and endurance by leveraging the lightweight design and efficient output of hub motors. In the field of driverless vehicles, hub motors offer flexible motion control, enhancing their autonomous driving and obstacle avoidance capabilities in complex environments.