Product Description

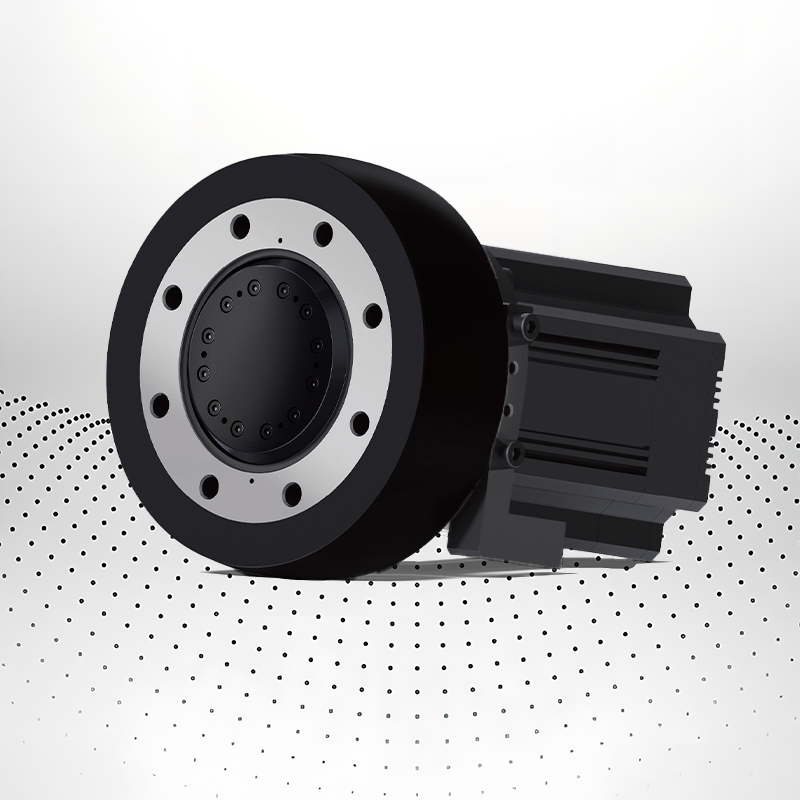

Hollow rotary platform is an ideal choice for rotary motion occasions. With high-quality bearings and sophisticated transmission components, it drives objects to rotate smoothly. As a powerful substitute for cam separators and DD motors, it is known for its high efficiency, high precision, high rigidity and high cost performance. From precision design to precise control system, high-precision operation is guaranteed in all aspects. With AC servo motors or stepper motors, it can flexibly realize multi-angle segmented control, meet digital control requirements, and significantly reduce equipment cost investment. With its many advantages, it shines in various rotary motion fields such as industrial production, providing practical convenience for users.

Functional Features

Compact structure:

The integrated design is exquisite and neat, and takes up very little space. The motor is connected to the side or the side axis, which is cleverly suitable for narrow spaces, greatly facilitating equipment integration and flexible application in places with limited space.

High precision:

The gear precision is below level 5, and the grinding process is exquisite. In coordination with high-precision bearings and advanced manufacturing processes, the repeat positioning accuracy is ±5 arc seconds, which accurately meets the stringent requirements of the precision field.

High stability:

Supported by cross roller bearings, the preload design gives it strong torque resistance. The rigidity is far superior to similar products, the vibration is weak during operation, and the rotation process is stable and worry-free.

Load capacity:

Adopting high-strength materials, the structural design has been optimized and improved. It can easily carry different types of objects from light to heavy, and can easily adapt to the diverse scenarios in industrial production.

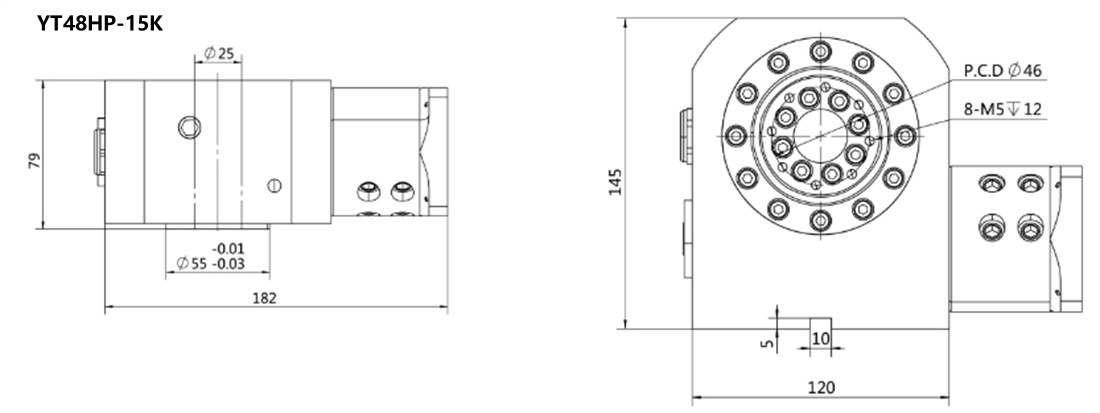

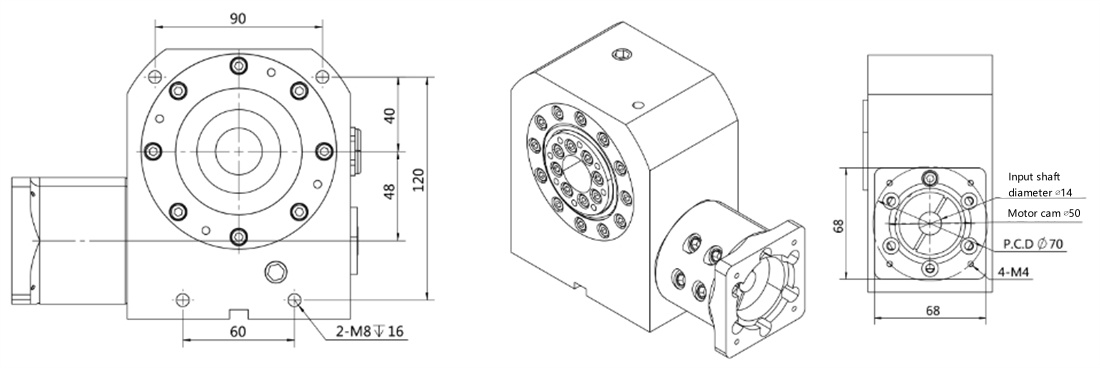

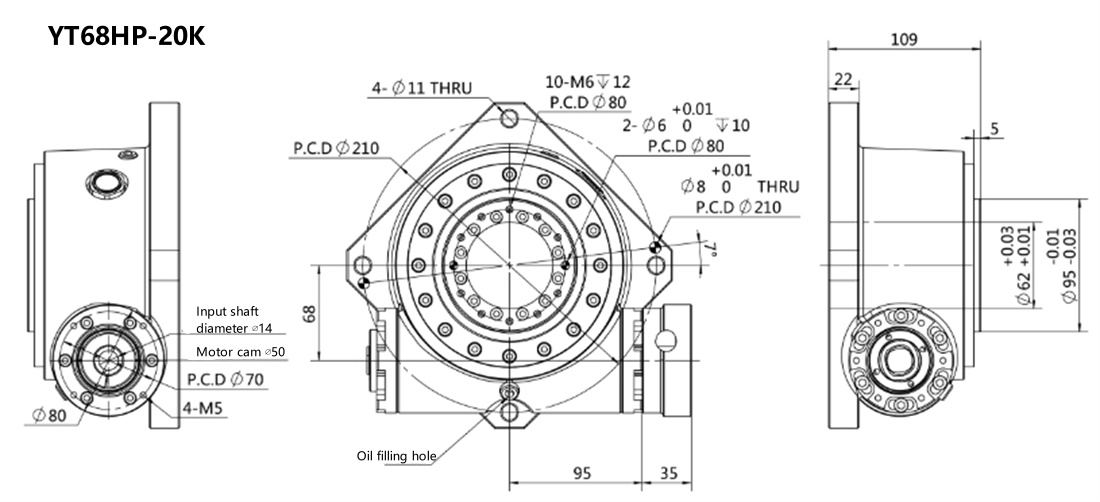

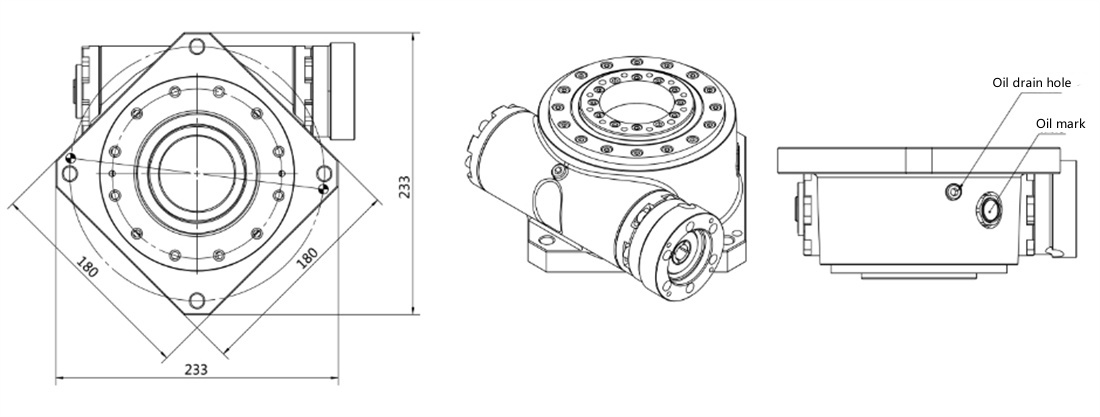

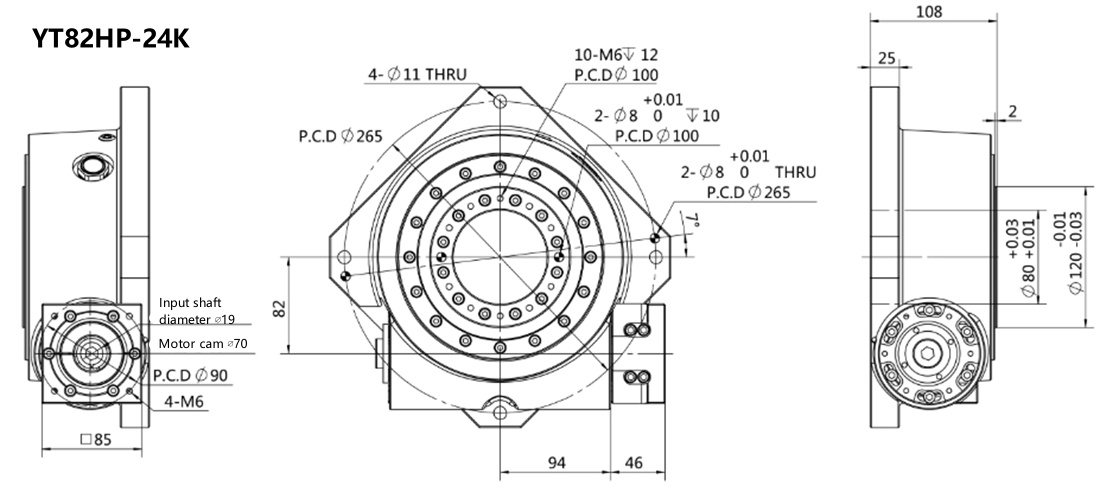

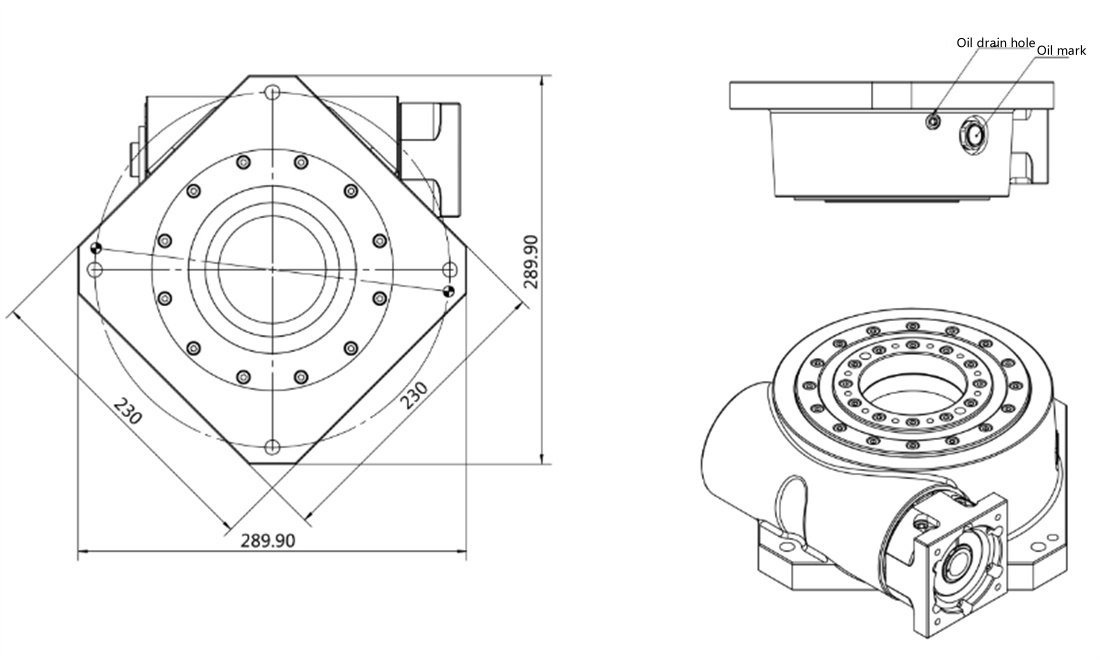

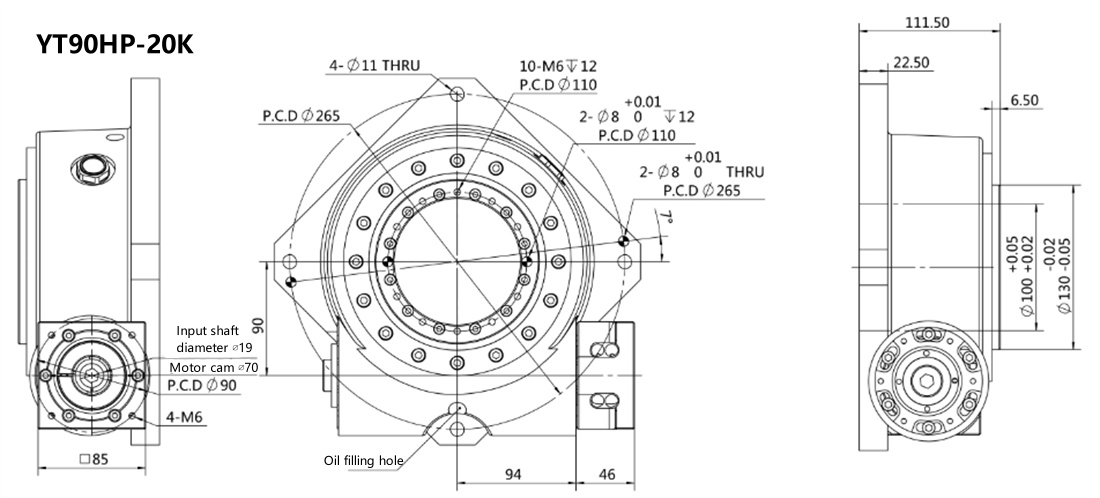

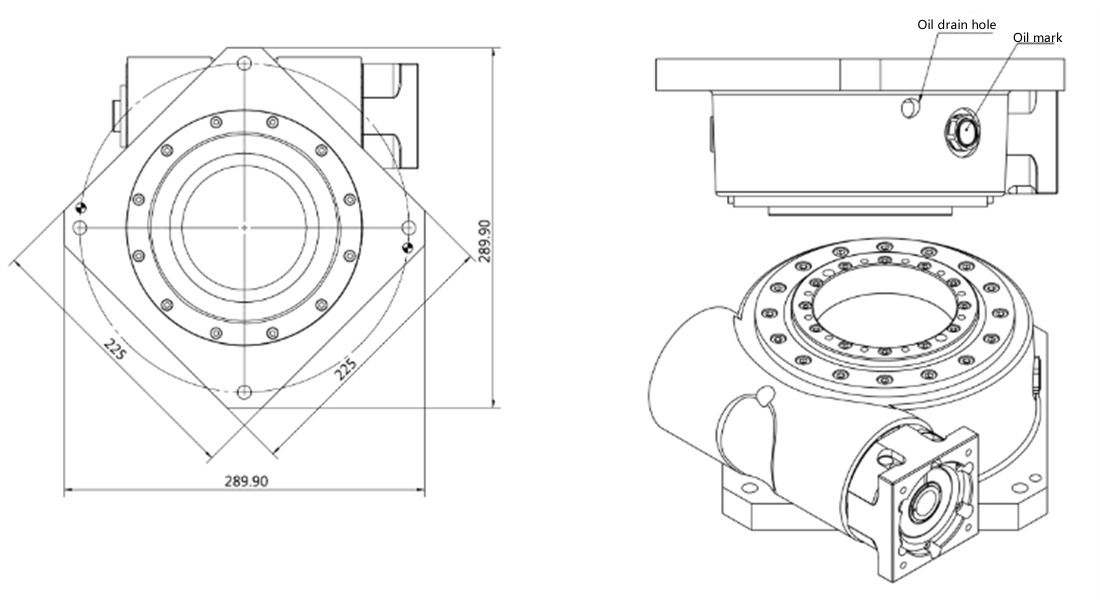

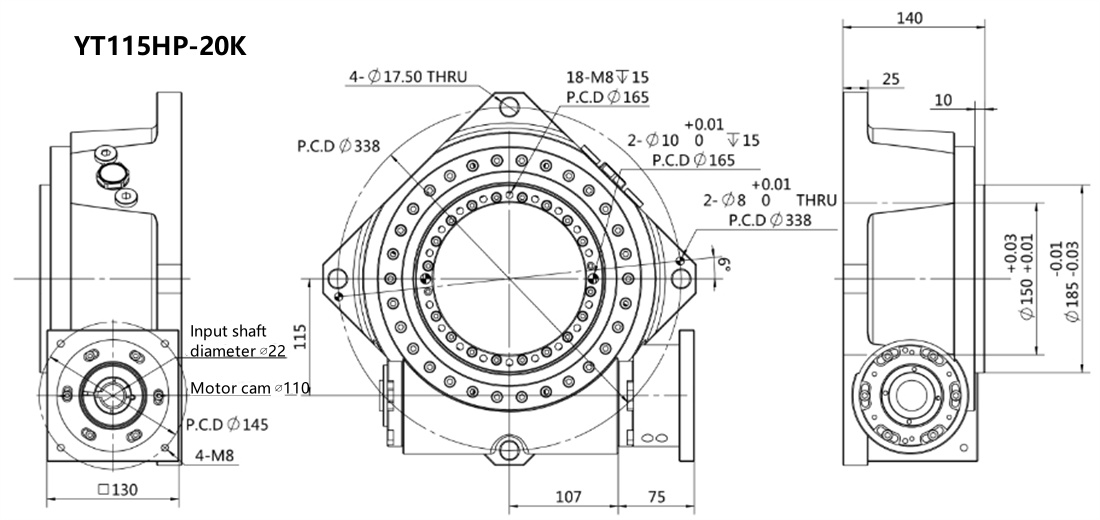

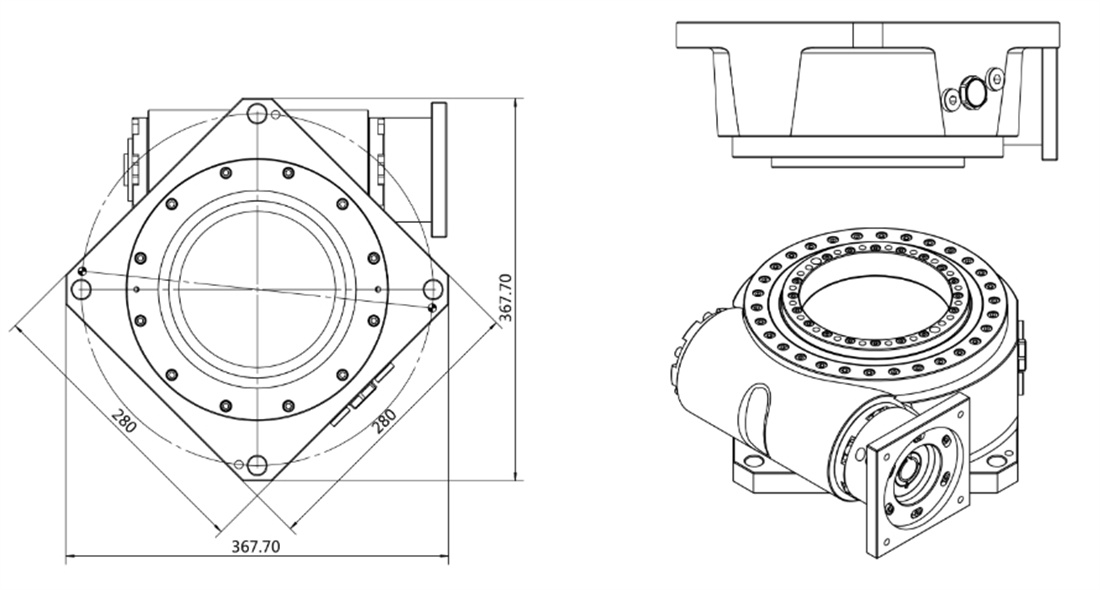

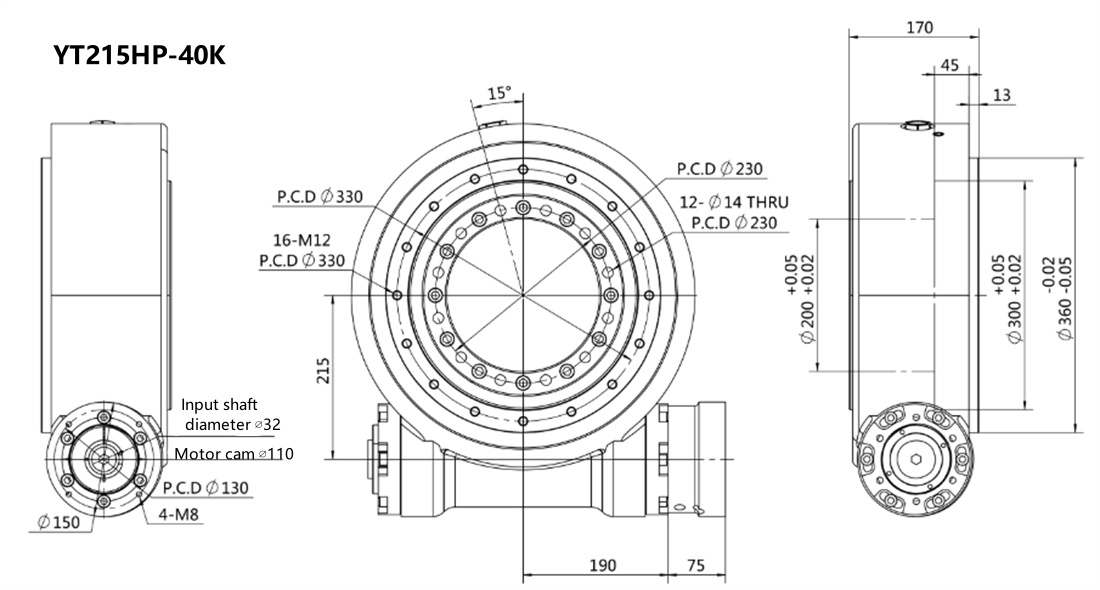

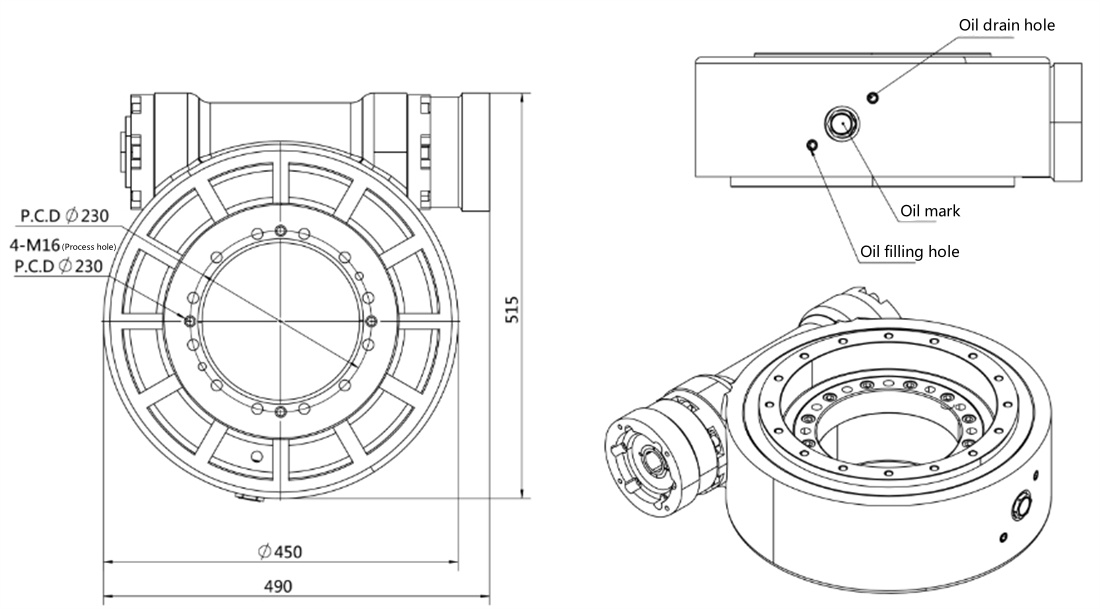

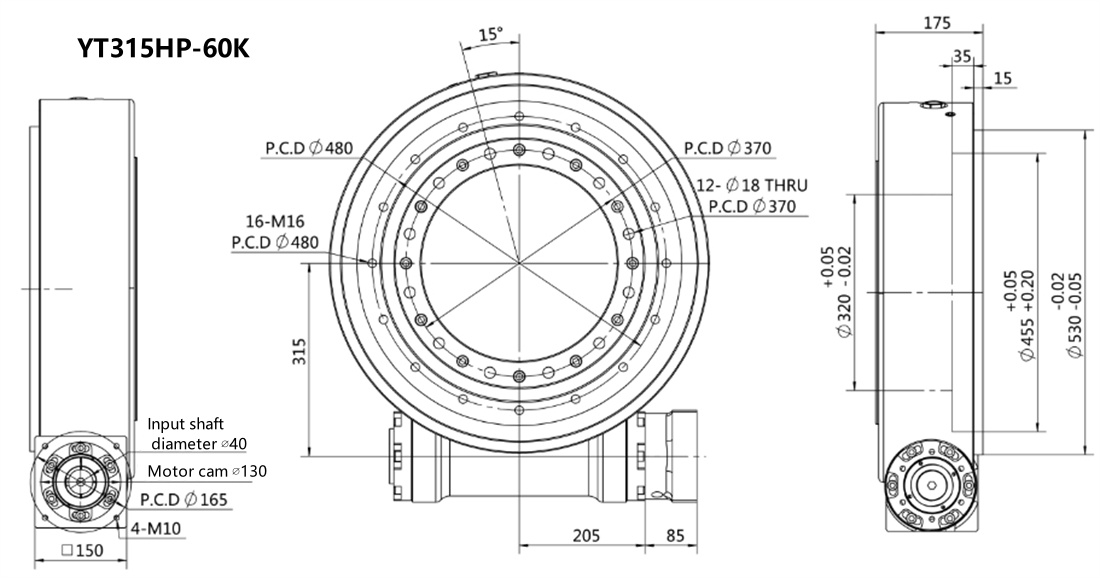

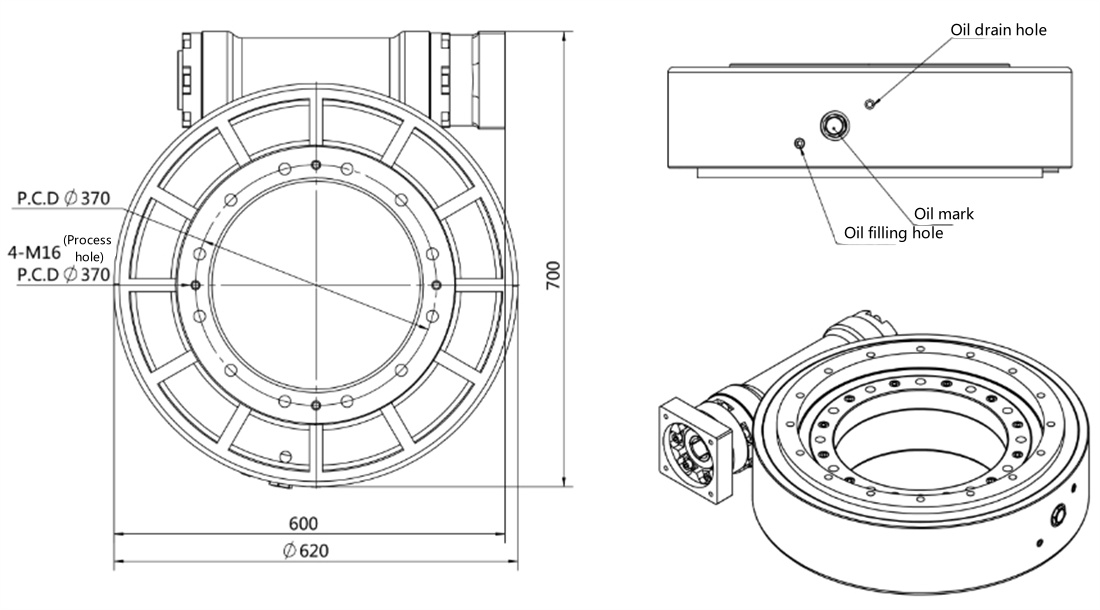

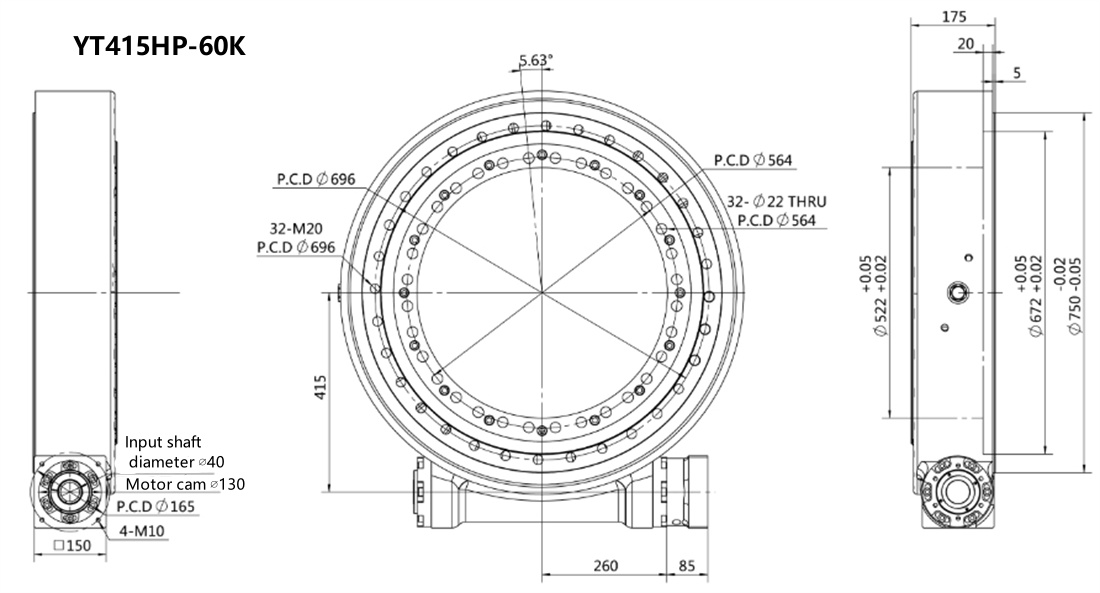

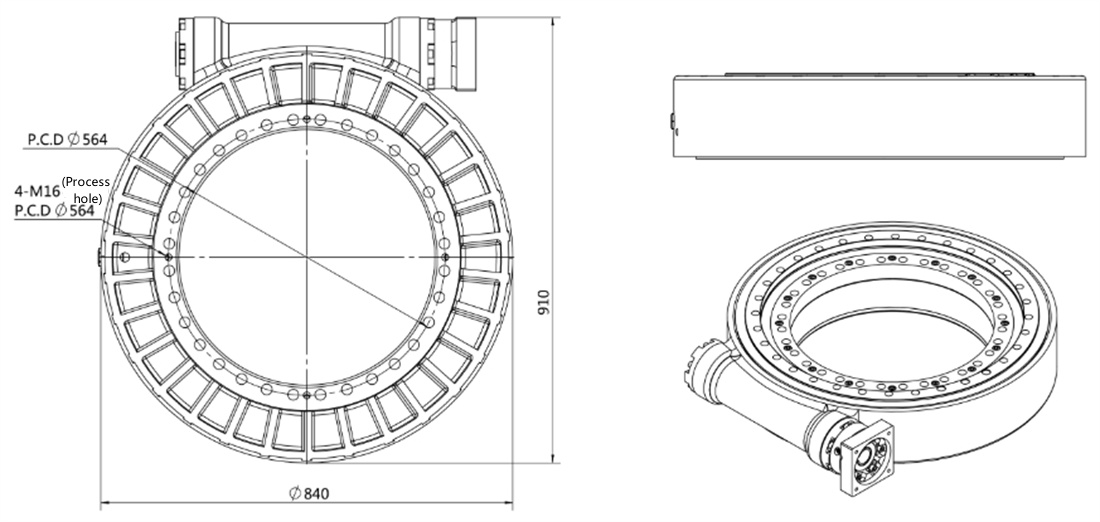

Dimensional drawing

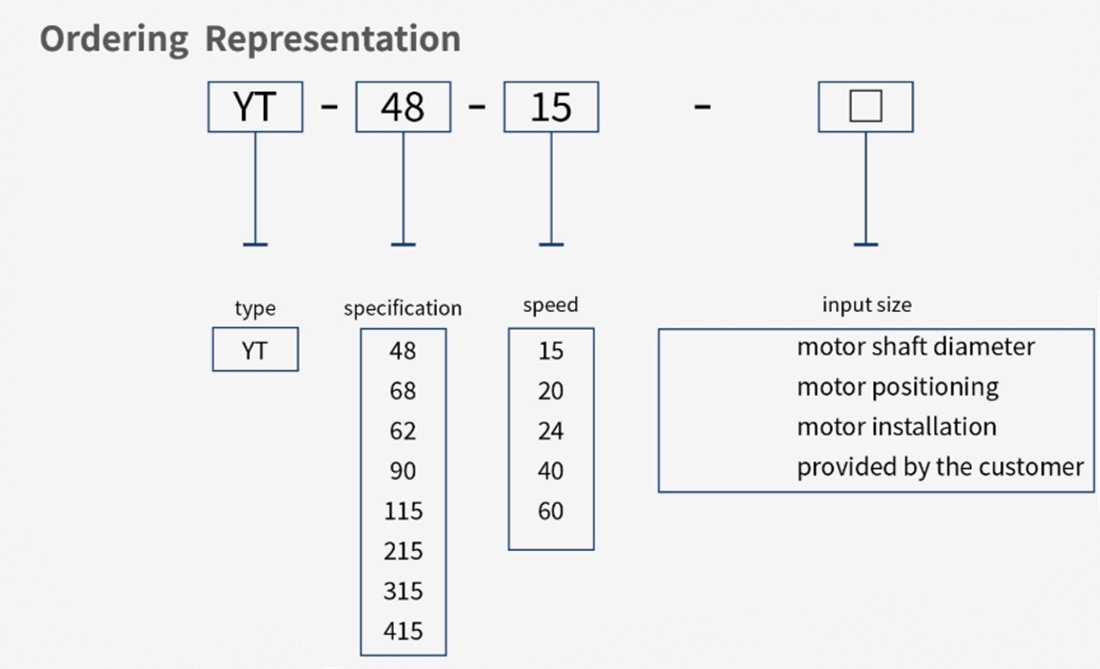

Model Description

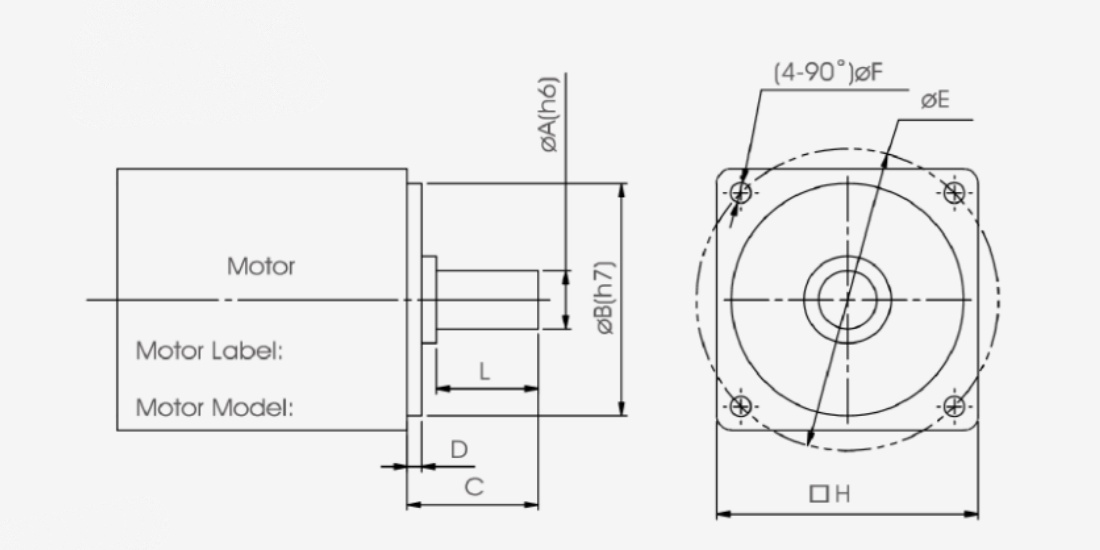

Motor Shaft Dia. | Flange Dia. | Motor Shaft Length | Flange Height | P.C.D of Bore | Bore Dia. | Motor Flange Square | Actual Length of Motor Shaft | Backlash |

∅A(h6) | ∅B(h7) | C | D | ∅E | ∅F | □H | L | P0/P1/P2 |

Product parameters

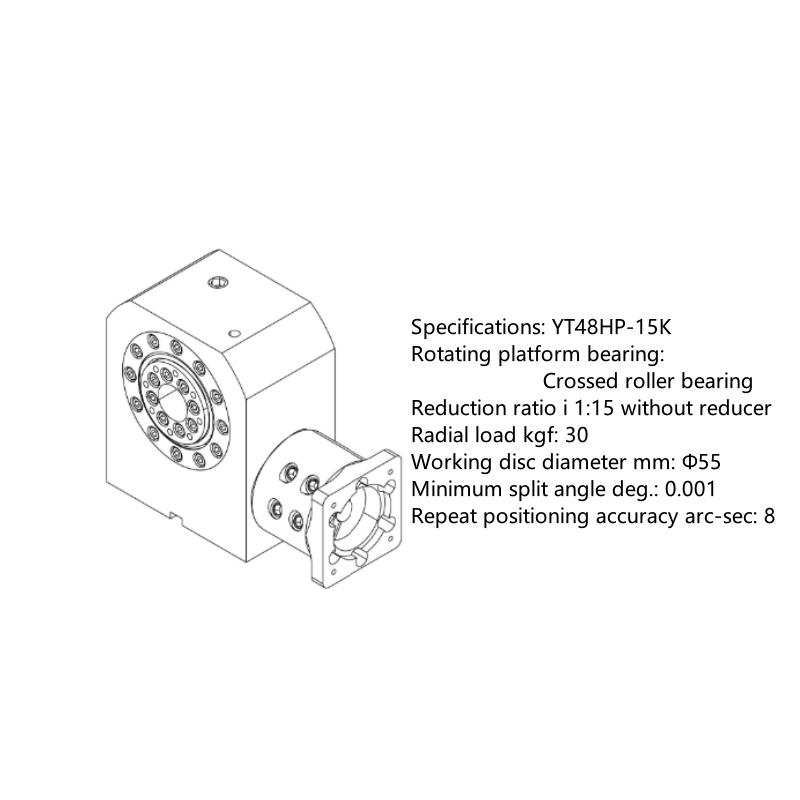

Specification | YT48HP-15K | ||

Rotating platform bearing | Cross roller bearing | Applicable motors | Frame servo :60 servo |

Reduction ratio i | (without reducer) | Center height mm | 90 |

Radial load kgf | 30 | motor | 400 |

Working disc diameter mm | Φ55 | Center hole diameter mm | Φ25 |

Min. Cutting angle deg. | 0.001 | Cutting accuracy s e c | ±25 |

Rotating platform bearing | 8 | Accuracy life hr | 20000 (intermittent operation) |

Warm reminder: The recommended maximum diameter of the rotary tooling disc is 400mm and the load-bearing capacity is 30kg | |||

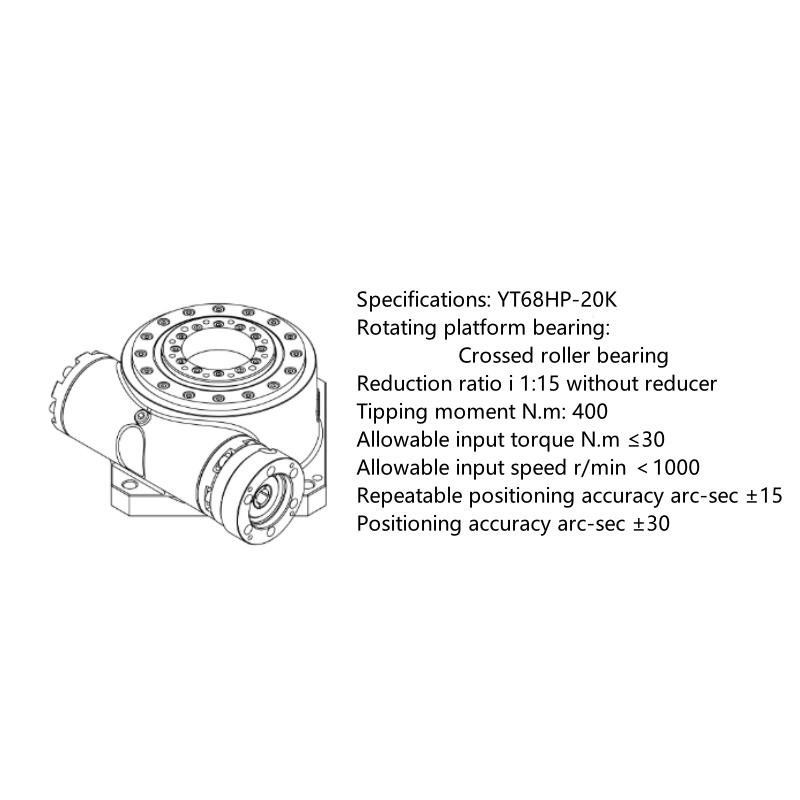

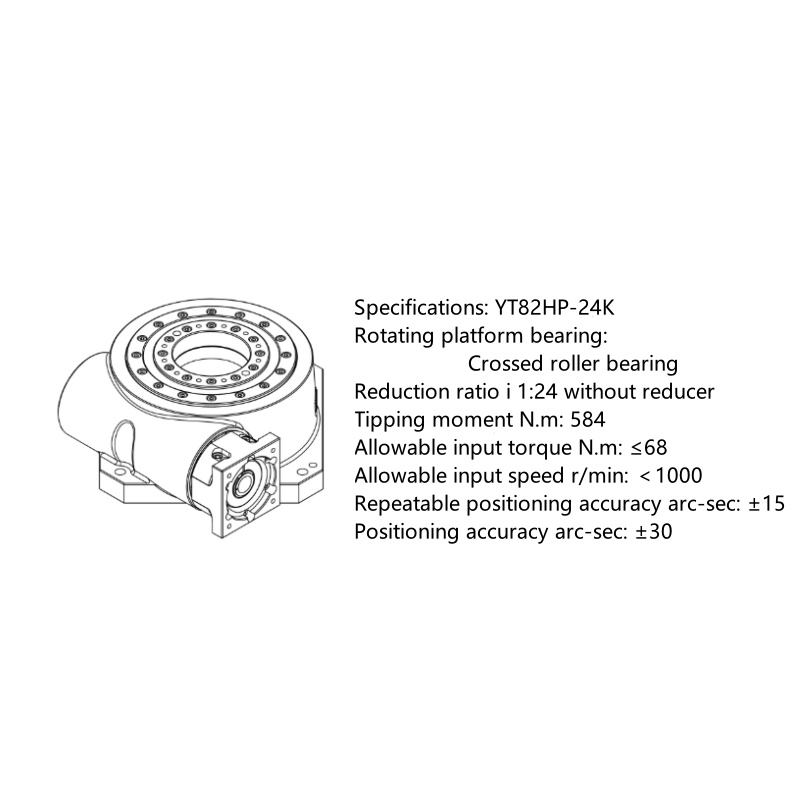

Specification | YT68HP-20K | YT82HP-24K | YT90HP-20K | YT115HP-20K | YT215HP-40K | YT315HP-60K | YT415HP-60K |

Rotating platform bearing | Cross roller bearing | ||||||

Reduction ratio i | 1:15(without reducer) | 1:24Excluding Reducer | 1:20 Excluding Reducer | 1:20Excluding Reducer | 1:40Excluding Reducer | 1:60Excluding Reducer | 1:60Excluding Reducer |

Tilting moment N.m | 400 | 584 | 625 | 1028 | 3749 | 13354 | 30000 |

Allowable input torque N.m | ≤30 | ≤68 | ≤72 | ≤90 | 1.9 | 2.5 | 4.5 |

Allowable input speed r/min | <1000 | <1000 | <1000 | <1000 | <800 | <800 | <800 |

Rotating platform bearing | ±15 | ||||||

Positioning accuracy arc-sec | ±30 | ||||||

Applicable motors | Frame servo :60 servo | Frame servo :80 servo | Frame servo :80 servo | Frame servo :130 servo | Frame servo :130 servo | Frame servo :180 servo | Frame servo :180 servo |

Motor type | Planetary reducer + servo motor + servo | ||||||

N.m Allowable inertia moment load N.m | 75 | 200 | 220 | 250 | 18000 | 28000 | 60000 |

Rotating platform flatness mm | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.03 | 0.03 |

Rotating platform concentricity mm | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.03 | 0.03 |

Accuracy life hr | 20000 (intermittent operation) | ||||||

Protection level | IP40 | ||||||

Reminder: The recommended maximum diameter of the rotary tooling plate is 800mm, and the load-bearing capacity is 500kg | |||||||

Tips: lf you need to install it upside down or sideways, please indicate it in advance when ordering. | |||||||

Application

The hollow rotary platform is integrated into the automation scenarios of multiple industries with high precision and high torque. In industrial manufacturing, it helps electronic assembly lines to accurately fit ultra-micro components and provides precision indexing detection for automobile transmission gears; in the field of robotics, it supports the high-speed sorting of 3C products by robotic arms and helps medical robots to achieve fine micro-operations; in precision instruments, it drives full-surface optical scanning of wafer tables and multi-angle marking of laser equipment, and the hollow structure optimizes the efficiency of wiring harness integration.

Quality Assurance

Product design and development: During the design phase of the central control rotary platform, a team of professional engineers gathered together to use advanced computer-aided design (CAD) and simulation analysis software to perform fine simulation and optimization of core parts such as product structure, power transmission, and control logic to ensure the reliability and stability of product performance from the source. All design plans must undergo multiple rounds of internal review and test verification before they can enter the production stage.

Raw material procurement: Strictly screen raw material suppliers to establish long-term, stable and high-standard cooperative relationships. For each batch of raw materials, strict quality inspections are carried out, covering the composition analysis of metal materials, mechanical performance testing, electrical parameter testing of electronic components, reliability testing, etc. Only raw materials that meet or exceed industry standards will be allowed to be put into production to ensure the basic quality of the product.

Production process control: The production workshop operates in accordance with a strict quality management system, introduces automated production equipment and high-precision testing instruments, and realizes the standardization and refinement of the production process. At each key node of production, quality inspection points are set up to conduct real-time sampling and full inspections of semi-finished products, including component processing accuracy inspection, assembly quality inspection, and initial electrical performance testing. For quality problems that occur during the production process, the traceability and rectification mechanism is immediately activated to ensure that the problematic products do not flow into the next link.

Finished product inspection: Each central control rotary platform must undergo a comprehensive and rigorous finished product inspection process before leaving the factory. Inspection items include but are not limited to no-load operation test, full-load operation test, positioning accuracy test, repeated positioning accuracy test, noise and vibration test, electrical safety performance test, etc. Only equipment whose indicators fully meet the product quality standards will be labeled as qualified and allowed to leave the factory.

After-sale guarantee

If a product fails, our after-sales team will respond immediately and quickly arrange for professional technicians to communicate with you to understand the details of the failure. We will provide you with remote technical guidance and assist you in solving the problem according to the specific situation. At the same time, we also provide you with regular return visits to understand the use of the product and collect your opinions and suggestions in order to continuously optimize products and services. When the product is upgraded, we will also notify you in a timely manner and provide you with corresponding technical support and solutions to keep your equipment in good performance.