Product Description

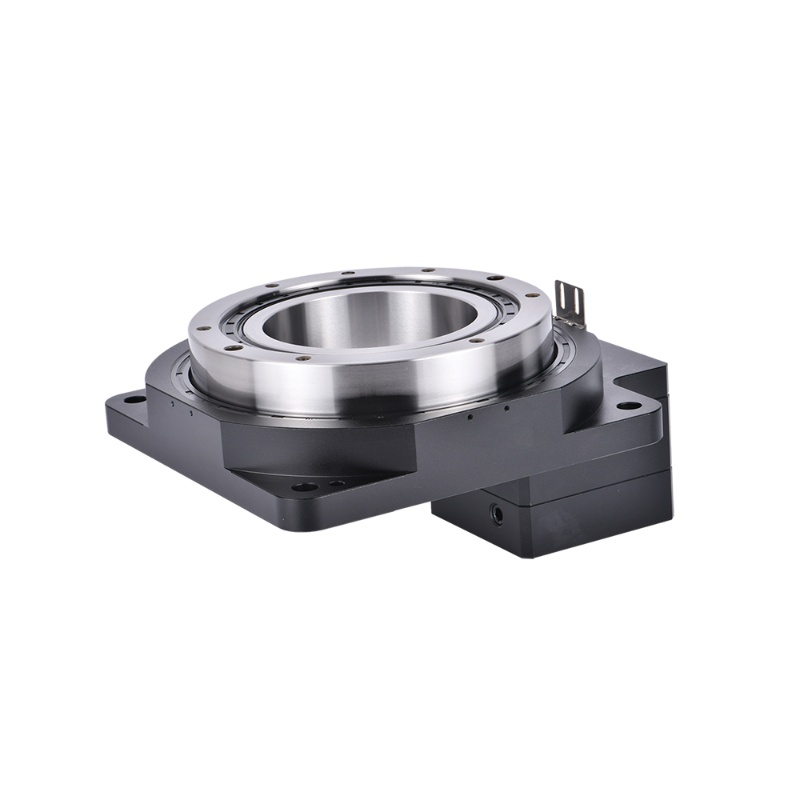

This series of products adopts military-grade crossed roller bearing design, which increases the bending moment resistance by 30%, greatly enhances the load stability, and is suitable for high-dynamic and high-rigidity application scenarios. The integrated dual encoder configuration (absolute + incremental) realizes full closed-loop control, with a position repeatability of ±0.005mm and more accurate dynamic response. The harmonic reducer is deeply integrated with the frameless torque motor, and the torque density is increased by 25%. It also has low backlash (<1arcmin) and low vibration characteristics. Optional temperature and vibration sensors can be used to realize intelligent status monitoring, providing reliable power solutions for collaborative robots, precision equipment and special equipment.

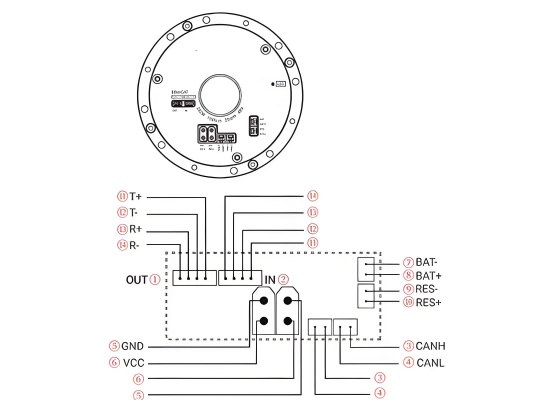

Port Definition | Port Description |

①EtherCAT_OUT | EtherCAT output |

②EtherCAT_In | EtherCAT input |

③CAN_H | CAN_H network signal terminal |

④CAN_L | CAN_L network signal terminal |

⑤GND | Power supply negative pole |

⑥VCC | Power supply positive pole |

⑦BAT- | Multi-turn battery negative pole |

⑧BAT+ | Multi-turn battery positive pole |

⑨RES- | Discharge resistor port |

⑩RES+ | Discharge resistor port |

⑪ T+ | Master sends control command to module |

⑫ T- | Module sends status feedback to master |

⑬ R+ | Master reflects module status data |

⑭ R- | Module reflects master control command |

Application

The integrated harmonic joint module is a precision transmission device that highly integrates harmonic reducer, motor, encoder, sensor and drive control circuit, with the characteristics of high precision, high torque density, light weight and low backlash. It has a wide range of applications, especially in industrial robots, aerospace, intelligent medical equipment, semiconductors and precision manufacturing, special robots and new energy and automation equipment, etc., which require precision motion control.

Product parameters

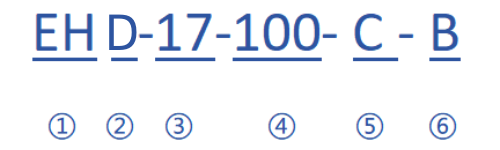

① EH represents the series name: integrated harmonic module ② S: single encoder D: dual encoder

① EH represents the series name: integrated harmonic module ② S: single encoder D: dual encoder

③ Harmonic model For example: 14/17/20/25/32, etc. ④ Reduction ratio 1:100

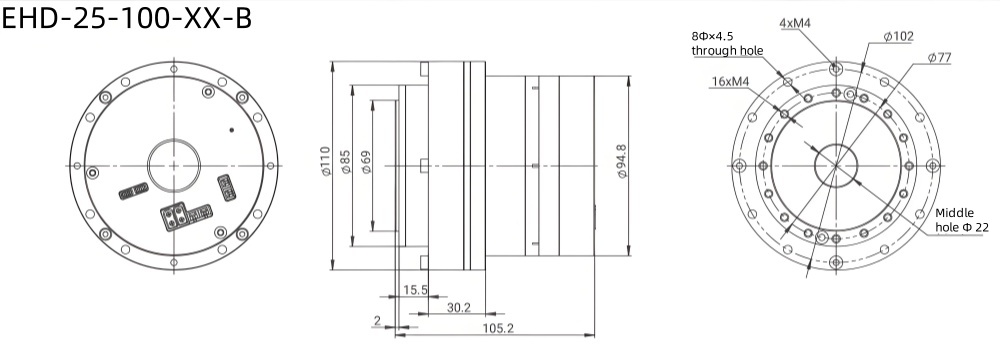

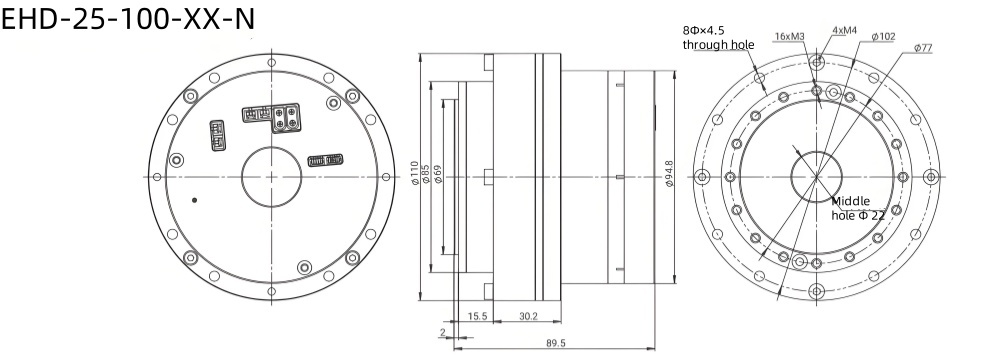

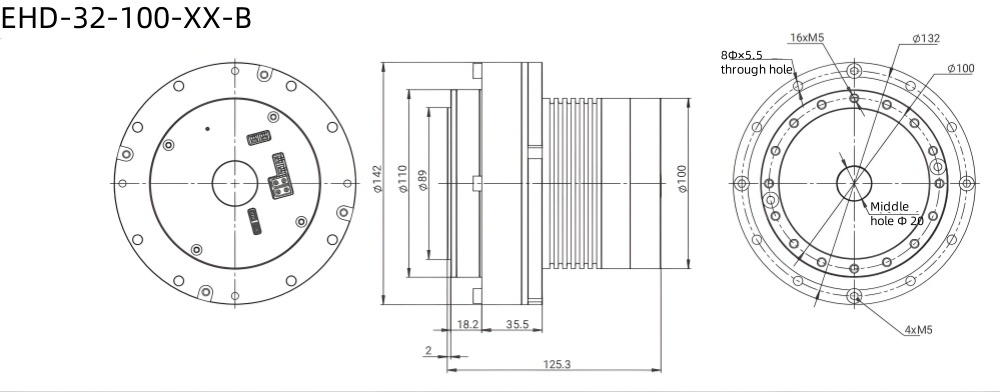

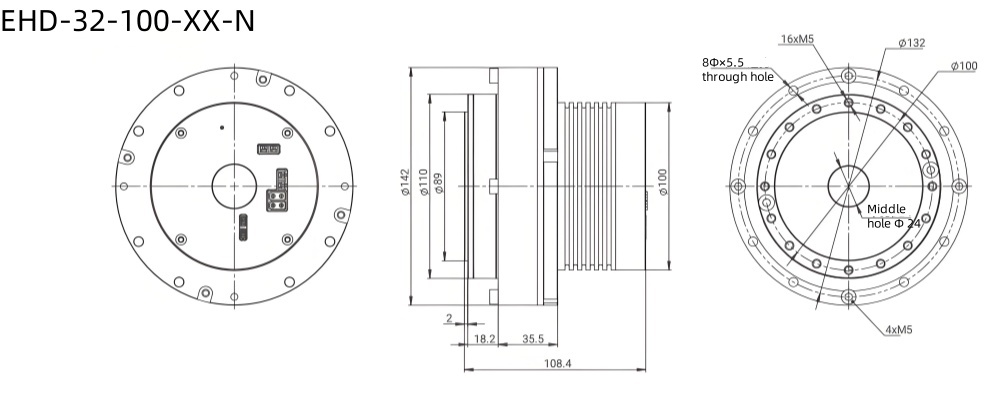

⑤ Communication method C/E: CANbus or EtherCAT ⑥ N: No brake B: Brake

Parameters | Unit | EH - 14 | EH-17 | EH-20 | EH-25 | EH-32 |

Gear ratio | - | 100 | 100 | 100 | 100 | 100 |

Input Voltage | V | 48 | 48 | 48 | 48 | 48 |

No Load Speed | RPM | 30 | 30 | 30 | 30 | 20 |

No Load Current | A | 0.9 | 145 | 2.59 | 1.61 | 3.9 |

Rated Speed | RPM | 25 | 25 | 25 | 25 | 18 |

Rated Torque | N.m | 11 | 35 | 50 | 108 | 150 |

Rated Power | W | 100 | 180 | 250 | 400 | 700 |

Rated Current | A | 6.5 | 9 | 13 | 16 | 20 |

Peak Torque | N.m | 28 | 54 | 80 | 157 | 229 |

Peak Current | A | 16.25 | 13.86 | 20.8 | 23.2 | 33.44 |

Back - EMF Constant | Vdc/kgm | 1.39 | 2.79 | 2.79 | 4.89 | 6.28 |

Torque Constant | N.m/A | 0.02 | 0.04 | 0.04 | 0.07 | 0.09 |

Phase Resistance | Ω | 0.62 | 0.7 | 0.36 | 0.155 | 0.08 |

Phase Inductance | mH | 0.43 | 0.47 | 0.51 | 0.33 | 0.18 |

Pole Pair | - | 10 | 10 | 10 | 10 | 10 |

3 Phase Connection | - | Y | Y | Y | Y | Y |

Backlash | Arcsec | - | <20 | <20 | <20 | <20 |

Encoder Type&Interface | - | Dual encoder/ABS - 17bit | Dualencoder/ABS-17bit | Dualencoder/ABS-17bit | Dualencoder/ABS-17bit | Dualencoder/ABS-17bit |

Repeat Position Accuracy | Degree | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

Communication | - | CAN / EtherCAT | CAN /EtherCAT | CAN /EtherCAT | CAN/ EtherCAT | CAN /EtherCAT |

Insulation grade | - | F | F | F | F | F |

* Rated torque test method: Test at rated speed at an ambient temperature of 24 degrees Celsius (no other heat dissipation method). The motor torque reaches temperature equilibrium under a temperature rise of 60 degrees and can work for a long time. The rated torque value of the motor.

* Standard motors can support brakes or not.

* Standard motors do not have waterproof function. If IP54 is required, please contact sales before ordering.

* Standard motors support CANBUS and EtherCAT

FAQ

1. Does it support waterproof and dustproof? What is the protection level?

Yes, our joint modules can be customized with waterproof and dustproof functions according to customer needs. The standard version is not waterproof for indoor applications, and can be equipped with IP56 protection, which is suitable for certain outdoor or humid environments.

If you have higher protection requirements (such as IP67), you can contact us for customization.

2. Does it support customized reduction ratio?

Yes. We can provide customized solutions with different reduction ratios according to your application requirements.

The conventional reduction ratio range covers: 10:1 ~ 200:1, and the best combination can be matched according to load, speed, and torque requirements.

3. What is the difference between the single encoder and dual encoder versions?

The single encoder version monitors the rotation of the motor end and is suitable for general precision requirements; the dual encoder version monitors the motor end and the output end at the same time, which can effectively compensate for the backlash and elastic error, and is suitable for high-precision control and high safety requirements (such as collaborative robots, medical equipment).

4. What communication interfaces can the joint module support?

The standard version supports analog control (current/voltage command) or pulse command control;

According to the needs, it can be optionally equipped with support for industrial bus protocols such as CANopen, EtherCAT, Modbus-RTU, etc. (customization is required).

5. Does it support integrated drive and control? Can it be directly connected to the controller?

We provide optional integrated drive and control joint modules with built-in motor drivers and position servo controllers.

Users can directly control through the bus or pulse interface without external independent drivers, simplifying wiring and system integration.

6. Is there a standard 3D model file available for download?

Yes. We provide 3D model files in STEP format for all models, which is convenient for customers to quickly integrate mechanical design.

If you need to obtain it, please contact our sales staff to obtain the download link or data package.

7. What is the operating temperature range?

The standard operating temperature range is: -10°C ~ +50°C.

If you need to resist low or high temperature application environments (such as cold storage, hot working environment), you can customize special temperature control solutions.

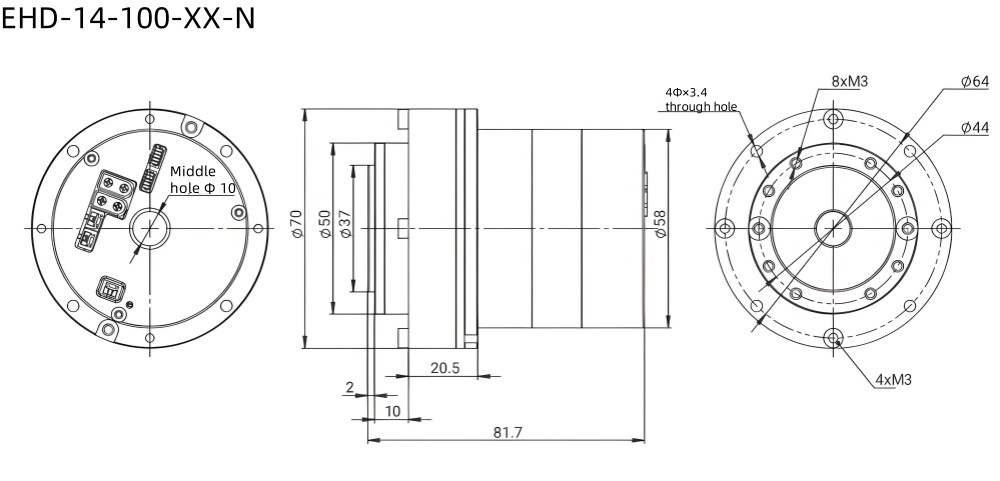

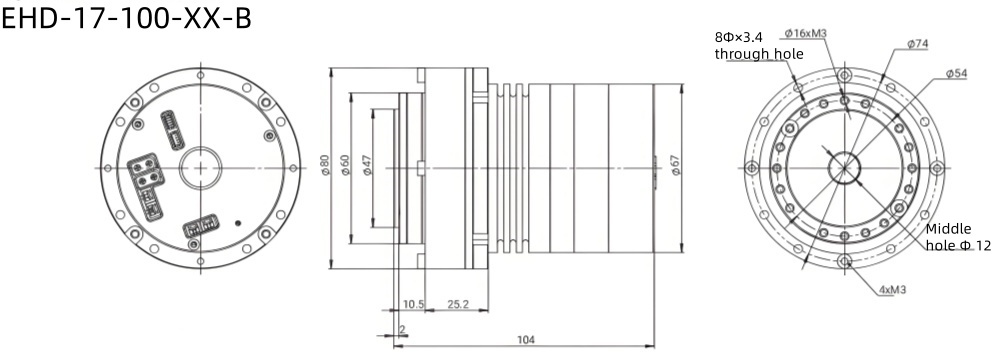

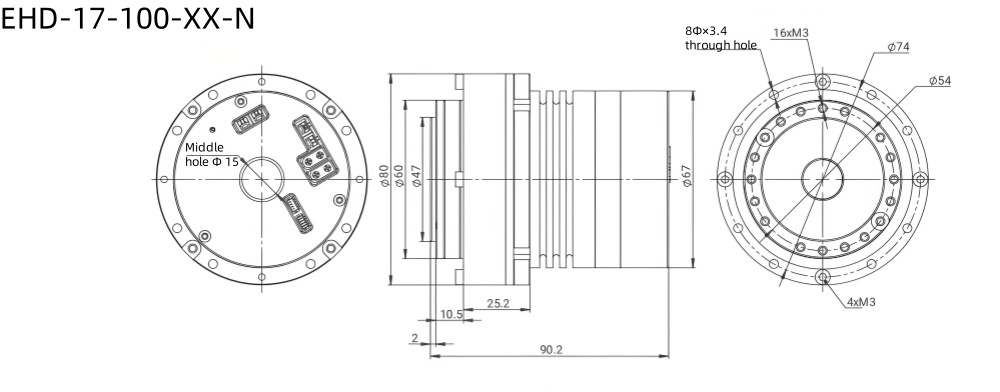

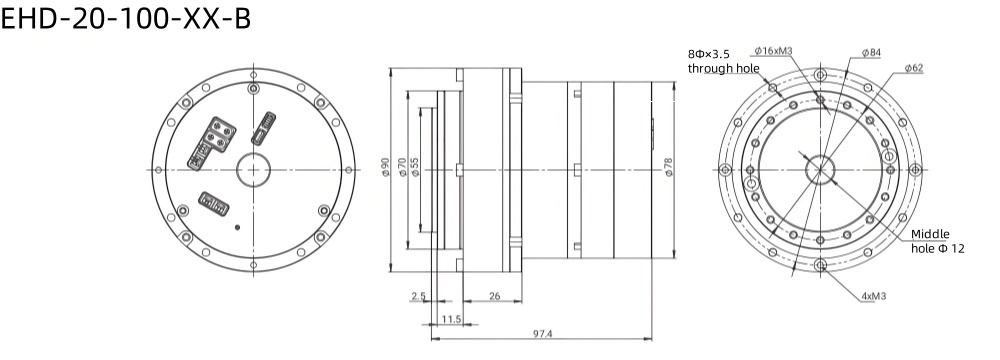

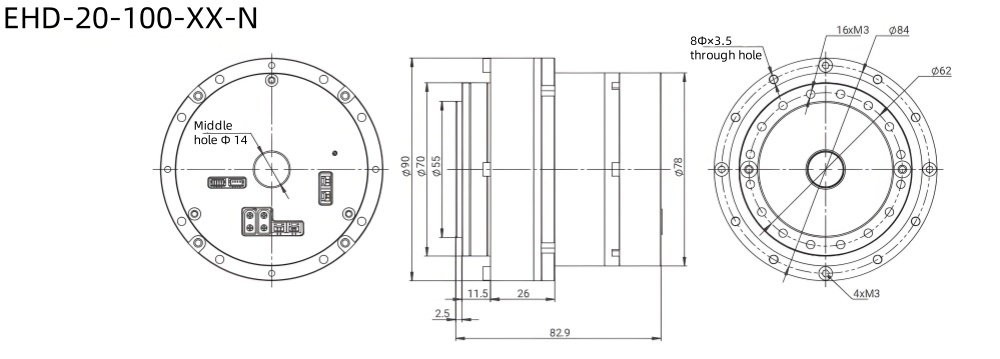

8. Can the joint module be designed to be hollow? Can it be wired?

Some models are hollow shaft designs, and the center aperture can be used for wiring, air pipes, water pipes, etc., which is convenient for realizing the functional layout of complex end effectors.

For specific center aperture dimensions, please refer to the model selection table or consult customer service.

9. How long is the standard delivery period and customized delivery period?

Standard model delivery period: usually 7-14 working days.

The delivery period for customized requirements (such as IP56 waterproof, reduction ratio customization, communication protocol customization, etc.) depends on specific requirements, generally 5-10 weeks.

10. How long is the warranty period? How about after-sales service?

All joint module products have a 12-month warranty period (under normal use).

We provide remote technical support, fault diagnosis guidance, and fast spare parts supply services. Paid repair and maintenance services are also available outside the warranty period.