Product Description

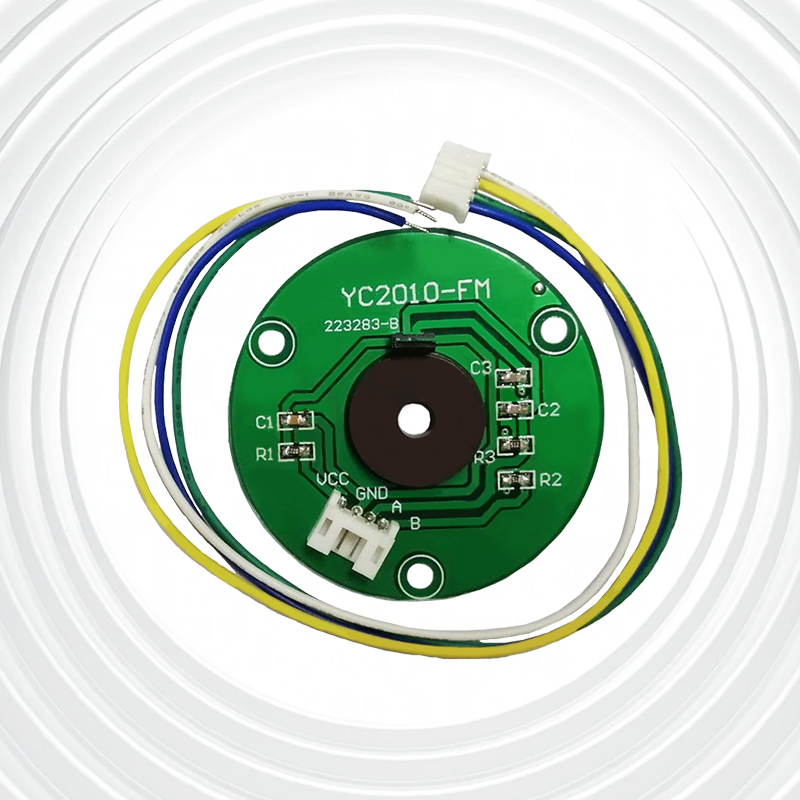

The YC2010-FM series magnetic encoders are high-performance, low-cost, two-channel incremental magnetic encoders suitable for any harsh environment. Each magnetic encoder contains a magnetic gate and a magnetic sensitive detection circuit, outputting square waves with a 90° orthogonal phase Angle between the two channels. The PCB board equipped with sensors, which is produced according to the motor diameter size and the main shaft size, is welded and fixed to the electrode at the motor tail, and the magnetic grid is sleeved on the tail shaft. It features fast response speed, strong shock resistance, long transmission distance, long service life in harsh environments and high reliability.

Product parameters

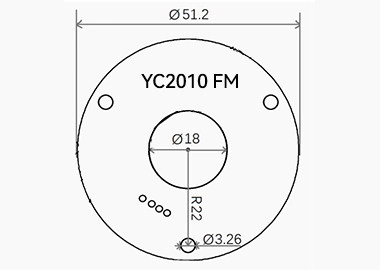

Working parameters | Applicable motor size range (mm)±0.5 | ||||

Type number | YC2010-FM P64 | YC2010-FM P100 | YC2010-FM P72 | Motor model | Brushless motor |

Working voltage (V) | 5~24 | 5 | 5 | Motor diameter A | >ø52 |

Operating temperature (℃) | -20~+80 | -20~+80 | -20~+80 | Fixed hole spacing B | ø44 |

Operating frequency (KHz) | 100 | 100 | 100 | Fixed hole diameter | ø3.2 |

Resolution rate | 16PPR | 25PPR | 18PPR | Tail shaft length | >8 |

Remarks | 12PPR refers to dual-channel output of A and B, with 12 pulse signals (TTL level) in each channel per turn. | Tail shaft diameter C | ø5 | ||

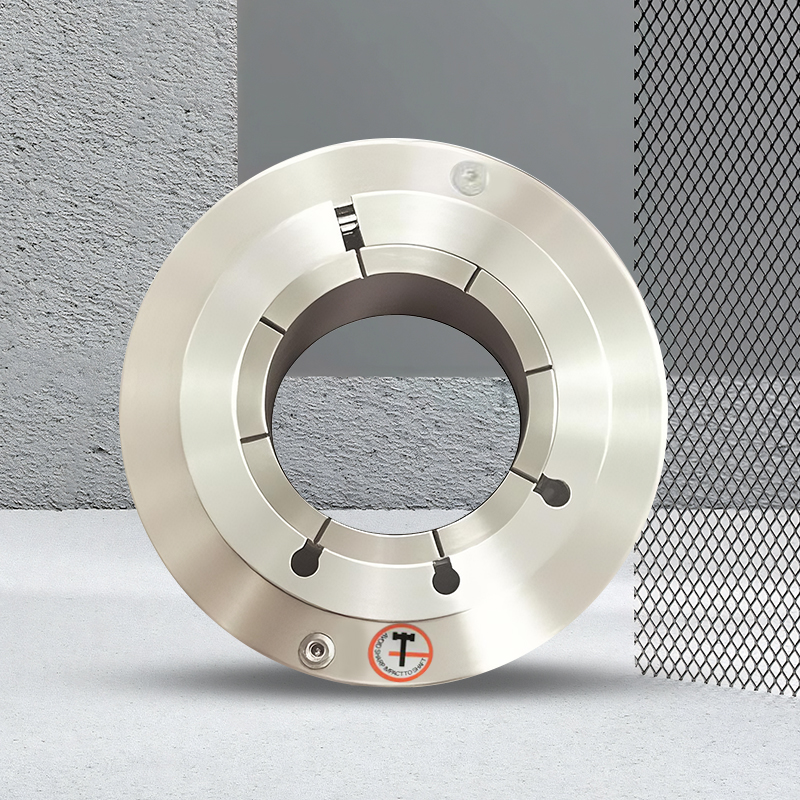

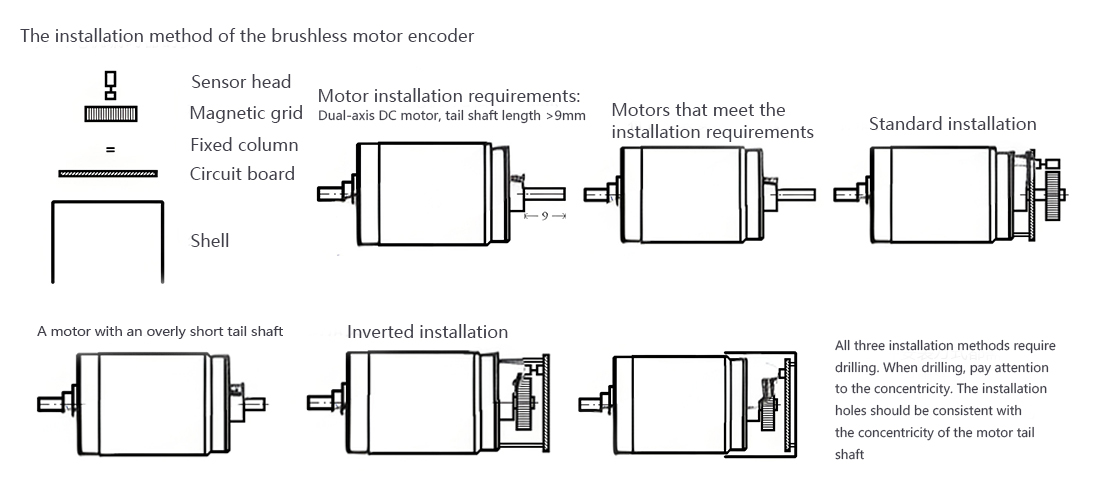

Installation method

| Wiring sequence: (from left to right) | ||

1 | Red | Sensor power supply | |

2 | LAN | Sensor ground wire | |

3 | Yellow | Signal A | |

4 | White | Signal B | |

Notes: | |||

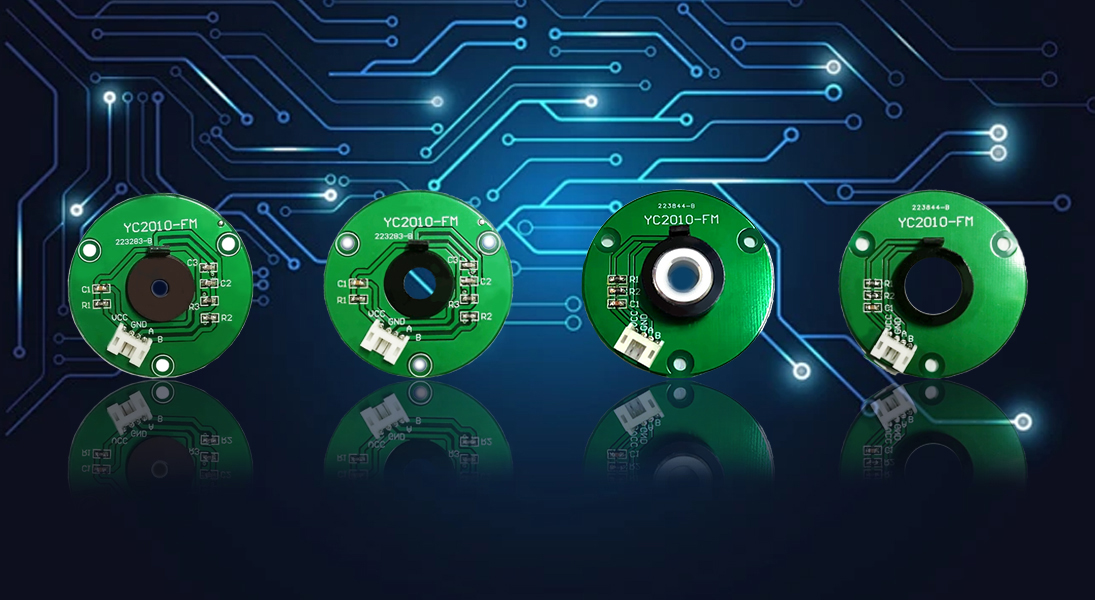

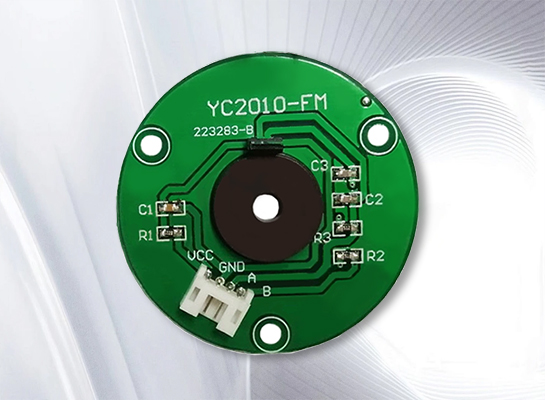

Product Display

Strong anti-interference ability: Adaptable to complex electromagnetic environments, with stable and reliable signals

High-precision positioning: Utilizing Hall magnetic sensitivity technology, it achieves precise Angle detection with high resolution

Wide voltage operation: Supports wide range DC power supply (such as 5-24V), with strong compatibility

Long-life design: Brushless structure with no mechanical wear and excellent durability

Compact and lightweight: Small in size, easy to integrate and install

Multi-functional output: Analog/digital signals are available for selection, suitable for various control systems

Strong environmental adaptability: resistant to temperature and dust, suitable for industrial automation, robotics and other scenarios

Quality Control

Application Cases

Dc brushless Hall magnetic encoders are mainly applied in motor and production line control in the field of industrial automation, steering systems in automotive electronics, mechanical arms and movement control of robots, precise operation of medical equipment, as well as smart home and unmanned aerial vehicles in consumer electronics.

Service

1. Precautions for Using Encoders

A place where the ambient temperature must not exceed the storage temperature; A place where the relative humidity must not exceed the storage

humidity; It cannot be in places with sharp temperature changes and fogging. Places close to corrosive gases and flammable gases; Stay away from

places with a lot of dust, salt and metal powder. Stay away from places where water, oil and medicine are used; Excessive vibration and shock can be

transmitted to the main body

2. Precautions for Installing Encoders

Electrical components must not be subjected to overvoltage or other phenomena. Please conduct static electricity assessment of the setting

environment, etc. Do not allow the motor power line to approach the encoder. The FG wire of the motor and the FG wire of the mechanical device

must be reliably grounded. Since the shielded wire is not connected to the encoder body, the shielded wire must be effectively connected to the

ground at the user end

3. Precautions on Wiring

When used at the specified power supply voltage, please pay attention to the decrease in power supply voltage amplitude caused by the long wiring.

Please do not use the encoder line and other power lines in the same pipe or bundle them in parallel. Please use twisted-pair wires for the signal line

and power line of the encoder. Please do not apply excessive force to the wire harness of the encoder, as there is a risk of wire breakage

4. Regarding the warranty of the encoder

Within twelve months of purchasing the products of our company, if any malfunction occurs due to correct use in accordance with the precautions

in the user manual, warning signs, etc., free warranty will be provided.

The following situations will be charged even within the warranty period: (Freight is at your own expense)

①. Faults and damages caused by the user landing during transportation or handling or improper installation;

②. Faults of this product caused by the machine connected to it;

③. Faults and damages caused by fire, salt water, corrosive gases, abnormal voltages, and other natural disasters such as earthquakes, lightning, wind, and floods;

④. Repair, adjustment or modification without the permission of our company (the label is not present or the outer cover is removed by oneself).

⑤. Malfunctions that occur when the user does not follow the usage methods and precautions described in the user manual.

⑥. Except where there are other agreements signed with the client.