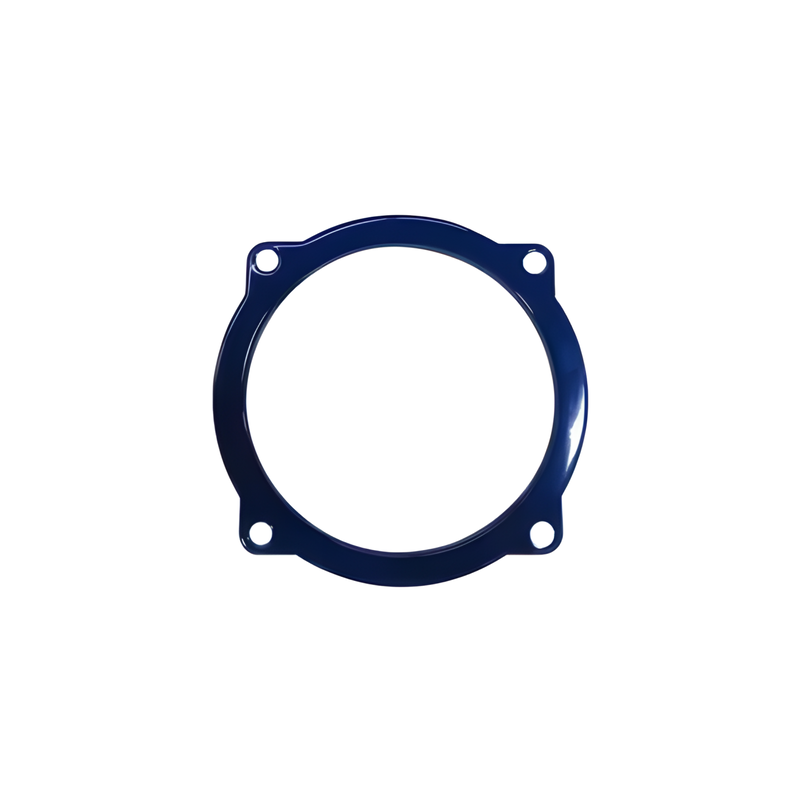

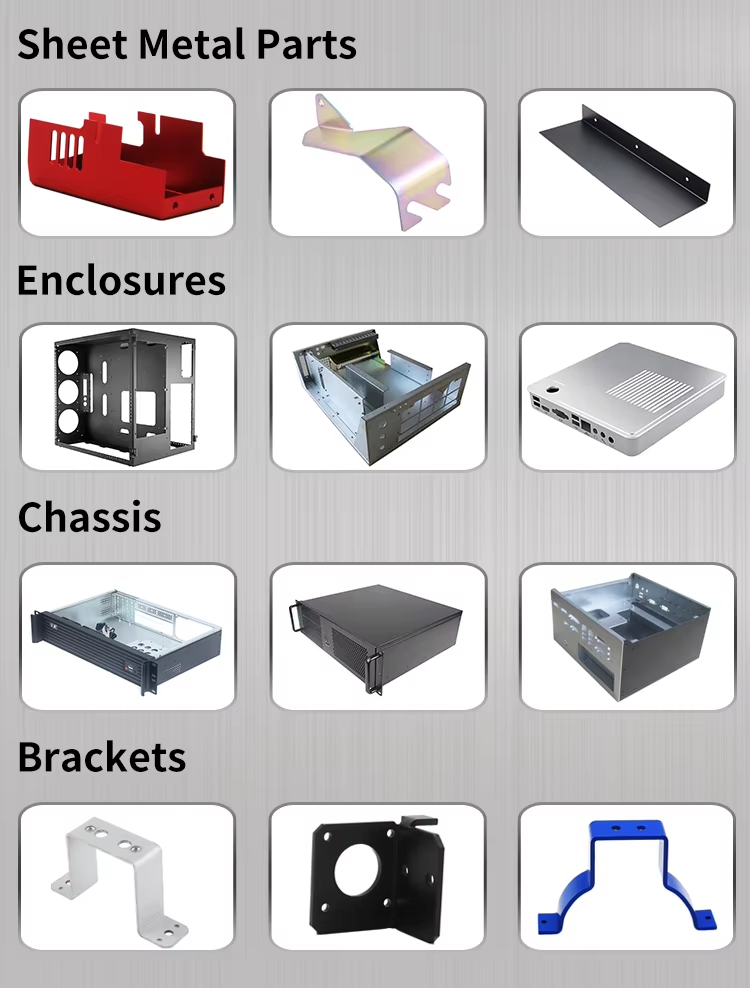

Product Description

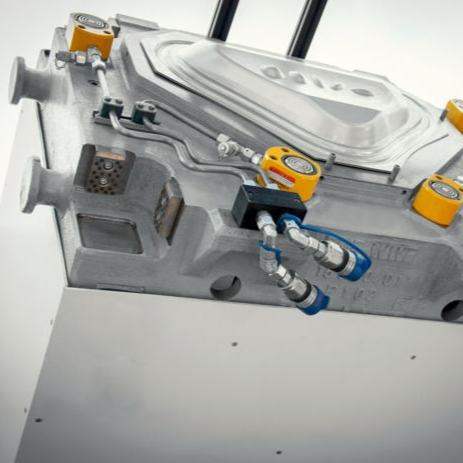

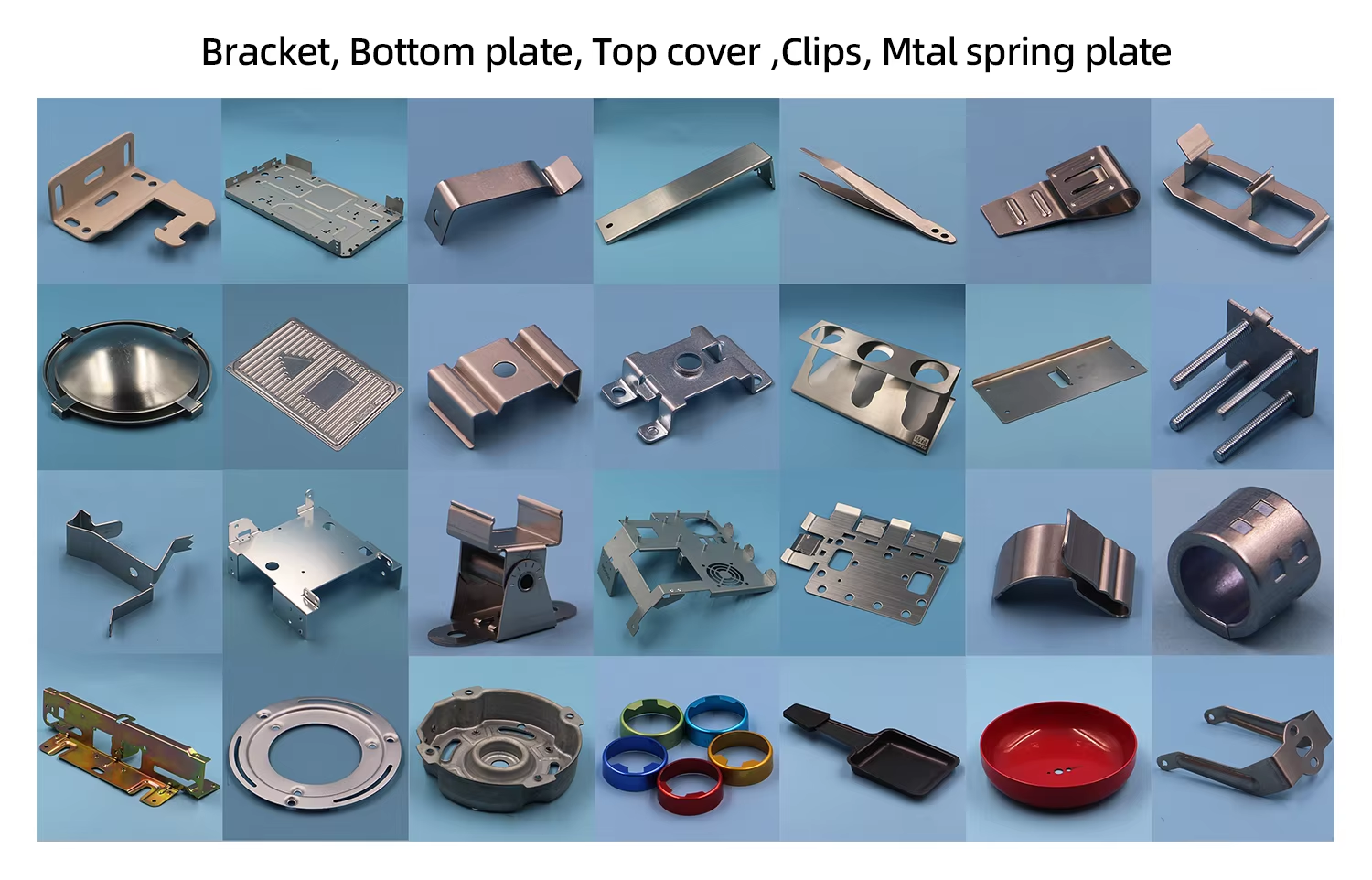

Metal stamping is a high-precision manufacturing process that uses dies and presses to form, cut, bend, or emboss sheet metal into specific shapes. It's ideal for mass production where consistent quality, speed, and cost-efficiency are essential.

✅ Fast and scalable production

✅ Precise and repeatable dimensions

✅ Versatile for complex or simple parts

Our Stamping parts components are engineered to meet the rigorous demands of the electrical industry. These precision-stamped parts are made from high-quality metals such as stainless steel, brass, and copper, ensuring excellent electrical conductivity, durability, and resistance to wear. They are commonly used in a variety of electrical applications, including connectors, terminals, battery contacts, switches, and power distribution systems.

Our stamping process delivers parts with tight tolerances, excellent surface finishes, and the ability to withstand high-temperature environments. With RoHS-compliant materials and customizable designs, our sheet metal stamping solutions provide reliable and long-lasting performance in critical electrical applications.

Supported Materials

Stainless Steel (e.g., SS304, SS316)

Aluminum & Aluminum Alloys

Cold/Hot Rolled Steel (SPCC, SGCC)

Copper & Brass

Specialty alloys based on customer needs

Key Benefits

| Benefit | Description |

| Customized Design Flexibility | Non-standard stamping allows for tailor-made components based on unique shapes, dimensions, or functional requirements that standard parts cannot fulfill. |

| High Production Efficiency | Once the stamping die is developed, production can be highly automated and scaled efficiently, making it ideal for medium to large batch manufacturing. |

| Cost-Effective Manufacturing | Compared to CNC machining or casting, metal stamping reduces material waste and production time, significantly lowering unit costs in mass production |

| High Dimensional Accuracy | Precision dies ensure tight tolerances and consistent part quality, typically within ±0.01 mm, suitable for components with strict fit or assembly requirements |

| Supports Complex Geometries | Enables the integration of multiple forming processes—such as punching, bending, flanging, and deep drawing—into a single step, enhancing design possibilities. |

| Excellent Repeatability and Consistency | The automated stamping process ensures stable quality across high-volume runs, essential for high-reliability applications. |

| Wide Material Compatibility | Compatible with a broad range of materials including carbon steel, stainless steel, aluminum, copper, and specialized alloys for different industry needs. |

| Faster Time to Market | Tooling development for stamping is relatively fast (typically 2–4 weeks), allowing quick prototyping and rapid transition to production |

Functional Features

Application

Power Distribution Equipment |

Connectors & Terminals |

Battery Contacts & Shields |

Switches & Sensors |

Product parameters

| Category | ข้อมูลจำเพาะ |

| Material Parameters | Material Types: Stainless steel, carbon steel, copper, aluminum, alloy steel, galvanized sheet, cold-rolled sheet, etc. |

| Material Thickness: 0.1mm – 10mm (common range) | |

| Hardness Requirements: According to standards such as HV, HRB, HRC (e.g., HRC30-50) | |

| Dimensional Parameters | Outer Dimensions: Customized based on drawings |

| Stamping Tolerance: ±0.01mm ~ ±0.1mm | |

| Hole Size and Spacing: Customized | |

| Process Requirements | Operations: Punching / Drawing / Flanging / Forming / Embossing / Shearing / Trimming |

| Welding: e.g., Spot welding, TIG welding | |

| Heat Treatment: e.g., Annealing, Quenching | |

| Inspection Standards | Appearance Inspection: No burrs, no cracks, no dents |

| Precision Inspection: Measuring tools such as calipers, CMM, projectors | |

| Functional Tests: Elasticity test, fatigue test, etc |

Custom Process

Contact

Negotiation

Mass Production

Logistic

Quality Control

1. Incoming Material Inspection

Material Certification: Verification of composition and properties (e.g., Cu, Sn content) against supplier CoA

Hardness Testing: Using Rockwell/Vickers scale to confirm material condition

Visual Inspection: Check for surface defects like rust, scratches, or warping

Dimensional Check: Thickness and flatness using calibrated micrometers/gauges

2. In-Process Quality Control

Stamping Accuracy: Real-time checks for dimensional tolerances (±0.01 – 0.05 mm)

Burr and Edge Inspection: Ensure all edges are smooth and safe using visual and touch methods

Tool Condition Monitoring: Periodic inspection for wear and deformation of dies

Sampling Plan: AQL-based sampling for dimension, form, and surface

3. Surface Treatment Inspection

Plating Thickness Test: XRF (X-ray fluorescence) used to confirm nickel, tin, or gold thickness

Adhesion Testing: Tape test or bend test to check coating bond

Corrosion Testing: Salt spray test (ASTM B117) for coated parts

4. Final Product Inspection

Functional Testing: Spring force, electrical conductivity, fit in assembly

100% Visual Check: Detect cracks, deformation, and contamination

Packaging QC: Verify quantity, lot labeling, ESD protection, and cleanliness

5. Documentation & Compliance

Inspection Reports: Maintained for traceability

RoHS / REACH Compliance: Documents available upon request

PPAP / FAI: Provided for automotive or OEM projects

SPC & CPK Analysis: For critical dimensions and process capability

Service

Storage

FAQ

1. What materials do you use for stamping parts?

We use high-conductivity and corrosion-resistant materials such as:

Stainless steel (301, 304)

Copper and copper alloys

Brass

Phosphor bronze

2. Can you produce custom designs?

Yes, we offer full custom stamping solutions based on your 2D/3D drawings or technical specifications. We support prototyping, tooling, and mass production.

3. What tolerances can you maintain?

Our precision stamping process allows for tight tolerances of ±0.01 mm, depending on material type and part geometry.

4. What applications are these parts used in?

Typical applications in the electrical industry include:

Electrical connectors and terminals

PCB-mounted components

Battery contacts and shields

Switches, relays, and sensors

Power distribution systems

5. Are your products compliant with environmental standards?

Yes, all materials and finishes used are RoHS and REACH compliant. Compliance documentation can be provided upon request.