Product Description

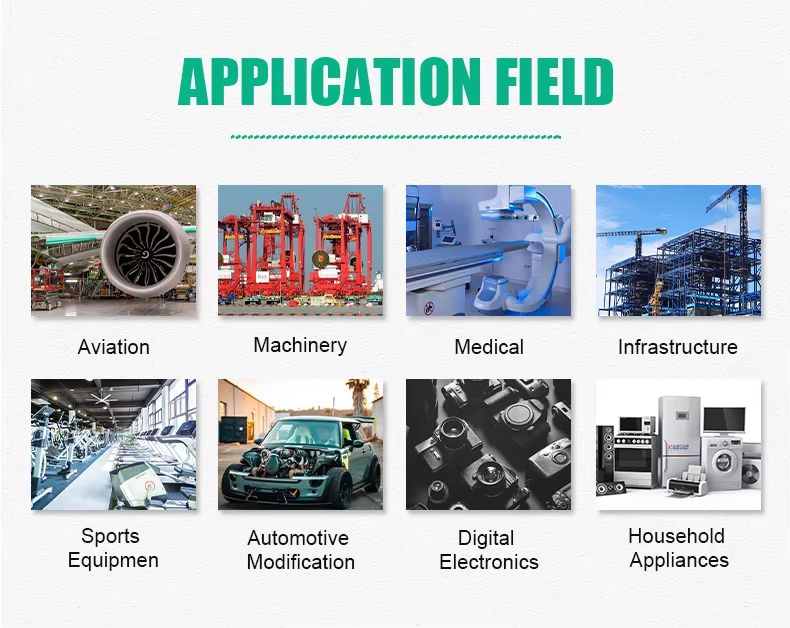

Our Swiss CNC Machining Services offer ultra-precise manufacturing solutions for complex and miniature components across industries such as aerospace, medical, electronics, robotics, and automotive. Using advanced Swiss-type CNC lathes, we can achieve extremely tight tolerances and high repeatability in both prototype and high-volume production.

These machines are especially effective for long, slender, and intricate parts that require exceptional dimensional accuracy and superior surface finishes. With multi-axis machining capability, we minimize setups and deliver faster lead times without compromising quality.

Functional Features

| Feature | Description |

| High Precision | Achieves tight tolerances down to ±0.005 mm, suitable for intricate parts. |

| Superior Surface Finish | Delivers finishes as smooth as Ra 0.4 µm, reducing or eliminating post-processing. |

| Multi-Axis Capability | Up to 7-axis simultaneous machining for complex geometries in one setup. |

| Optimized for Small Part | Specializes in long, slender, or miniature components |

| Fast Turnaround | High-speed machining with efficient cycle times for prototypes to mass production. |

| Versatile Material Support | Compatible with a wide range of metals and plastics |

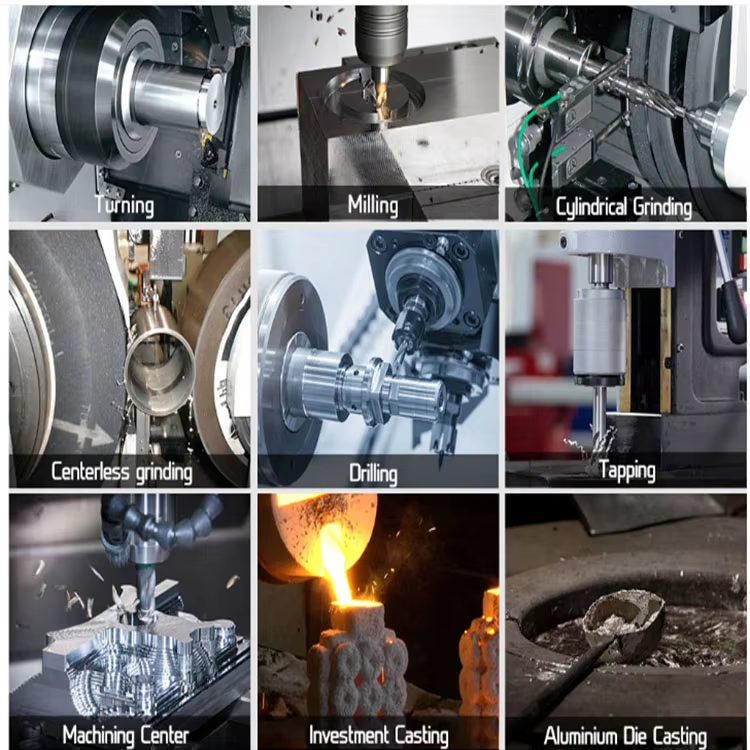

Product Display

Application

Product parameters

| Parameter | Specification |

| Material | Aluminum, Stainless Steel, Brass, Copper, Titanium, Plastics |

| Aluminum Grades | 6061, 7075, 2024, 5052, 6063, 5083, MIC-6 |

| Max Part Diameter | Ø 2 mm – 32 mm (up to 38 mm on request) |

| Max Part Length | Up to 600 mm |

| Tolerance Accuracy | ±0.005 mm or better |

| Surface Finish | Ra 0.4 µm or finer (machined) |

| Threading | Internal & external (metric, UNC, UNF, custom) |

| Hole Diameter Range | Ø 0.3 mm – Ø 25 mm |

| Volume Capacity | From 1 prototype to 1,000,000+ pcs |

Custom Process

Contact

Quotation

Production

Transportation

Quality Control

We are committed to delivering parts that meet or exceed industry standards through a rigorous quality control process at every stage—from incoming materials to final inspection before shipment.

| QC Item | Details |

| Certifications | ISO 9001:2015 / ISO 13485 (for medical applications) |

| Inspection Equipment | CMM (Coordinate Measuring Machine), Vision Systems, Micrometers, Calipers |

| First Article Inspection (FAI) | Available upon request with full dimensional report |

| In-Process Inspection | Continuous inspection during production using SPC (Statistical Process Control) |

| Final Inspection | 100% inspection of all critical dimensions before packaging |

| Material Certification | Available for all aluminum grades with full traceability |

| Surface Finish Verification | Ra surface roughness testing plus visual and tactile inspection |

| Documentation | QC reports, Certificate of Conformance (CoC), RoHS compliance (if required) |

| Tolerance Verification | Measurement accuracy up to ±0.005 mm or better, depending on part requirements |

Service

FAQ

1. What is Swiss CNC machining, and how is it different from conventional CNC turning?

Swiss CNC machining is ideal for producing small, high-precision parts. Unlike conventional CNC lathes, Swiss machines support the material very close to the cutting tool, significantly reducing deflection and improving accuracy—especially for long, slender, or intricate components.

2. What aluminum alloys do you work with?

We commonly machine the following aluminum grades:

6061-T6

7075-T6

2024-T3

5052-H32

5083

6063

MIC-6 (cast plate)

Custom aluminum alloys are also available upon request.

3. What tolerances can you achieve?

We routinely achieve tolerances of ±0.005 mm (5 microns) or better, depending on the part’s geometry and material. Tighter tolerances can be discussed for specialized applications.

4. What is your typical lead time?

Prototypes: 3–7 business days

Small to medium production runs: 1–2 weeks

High-volume production: 2–4 weeks, depending on complexity and quantity

Expedited services are available upon request.

5. Do you offer secondary processes like anodizing or assembly?

Yes, we provide a range of secondary services, including:

Anodizing (clear, black, or custom colors)

Bead blasting and polishing

Laser marking

Assembly and packaging