คำอธิบายผลิตภัณฑ์

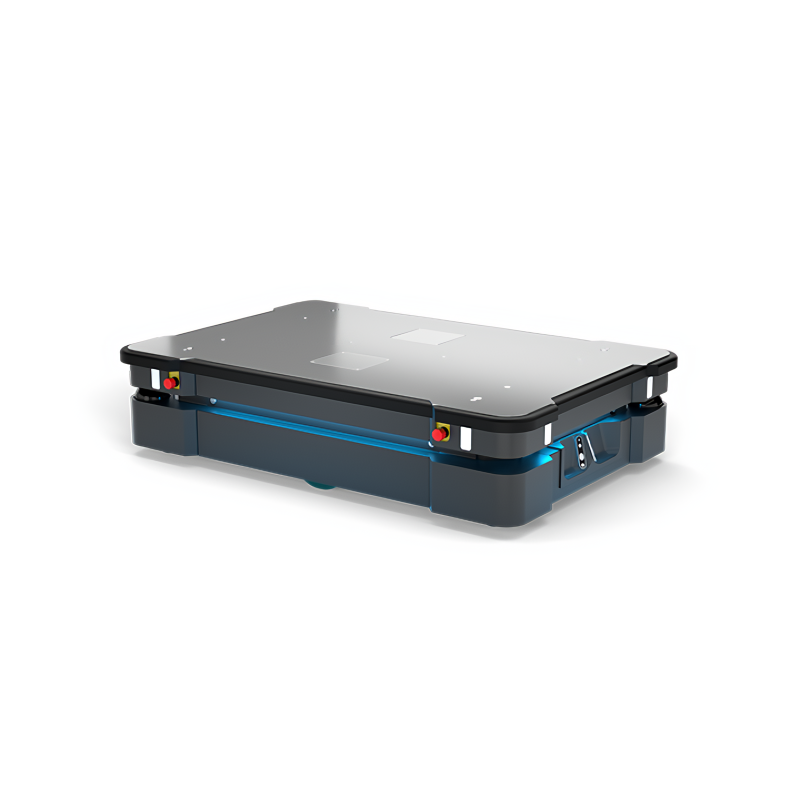

AegisLift 2000 is a next-generation Autonomous Mobile Robot (AMR) engineered for transporting heavy materials within warehouses and manufacturing environments. With a payload capacity of up to 2,000 kg, it operates without the need for fixed infrastructure like magnetic strips or laser guidance. Its smart navigation, dynamic obstacle avoidance, and safety-driven design make it ideal for large-scale operations that demand high efficiency and flexibility.

Product Features

Supports payloads: Up to 2,000 kg

Maximum speed: 2.1 m/s

Power system:

Auto-charging capability

Integrated automation controller:

IoT connectivity

Built-in safety systems

Multi-axis motion coordination

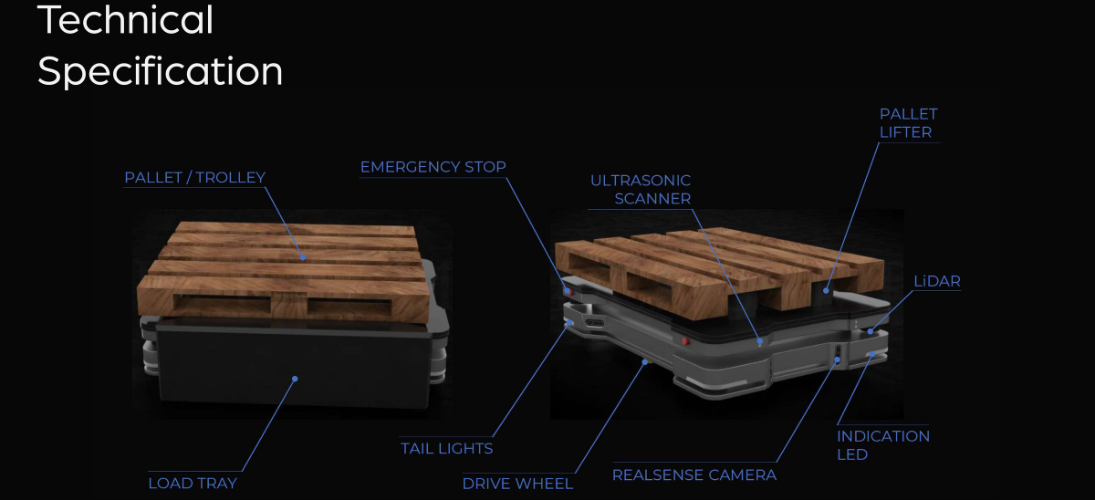

Safety system: 3-layer intelligent protection featuring:

3D Depth Camera

LiDAR

Ultrasonic Sensors

Navigation:

Real-time path planning

Dynamic obstacle avoidance

Operational capability:

Suitable for both day and night operations

System integration:

Supports 3rd-party WMS integration via API

Top module compatibility:

Pallet Lifter

Conveyor

Flat Bed / Tugger

คุณสมบัติของผลิตภัณฑ์

AegisLift 2000 is deployed to transport steel frames and engine blocks, reducing forklift traffic and improving floor safety

Used in the final assembly zone to move completed parts to storage, cutting down 60% of manual cart handling.

Handles palletized containers up to 2 tons with minimal human contact, enhancing compliance with safety regulations.

พารามิเตอร์ผลิตภัณฑ์

AegisLift 2000

Parameter | Specification |

Maximum Payload | 1,500 kg |

Maximum Speed | 2.1 m/s or 7.6 km/h or 4.7 mph |

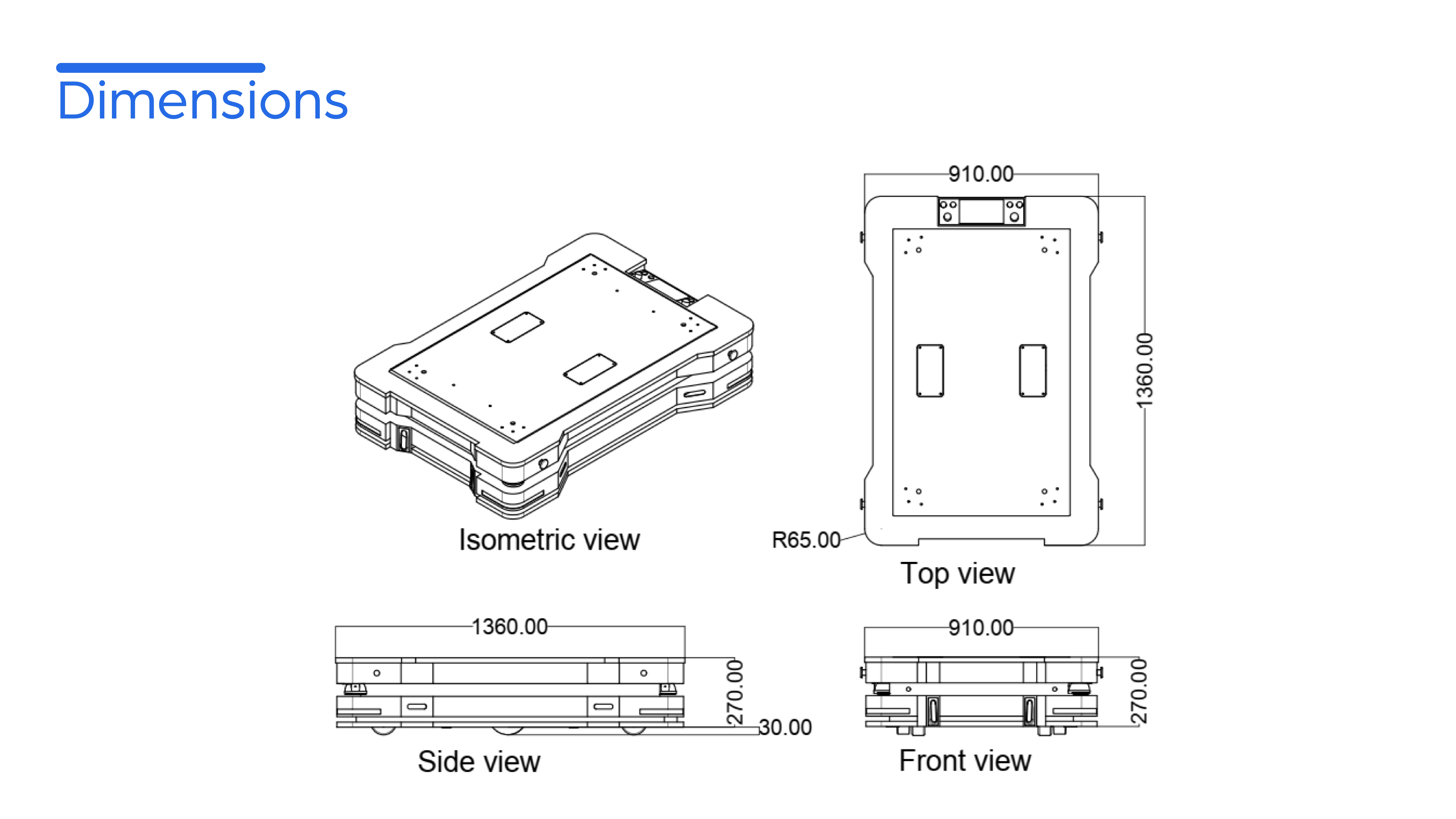

Dimensions | 1,360 mm × 910 mm × 300 mm |

Ground Clearance | 30 mm or 1.2 inches |

Running Time | Up to 12 hours |

Turning Radius | 0 mm (can rotate in place) |

Charging Time | 3.5 hours (standard) / 1 hour (super charger, 0–100%) |

Safety Features | Emergency button, intelligent LED lights, EN-1525 & CE certified |

AegisLift 2100

Parameter | Specification |

Maximum Payload | 1,500 kg |

Maximum Speed | 2.1 m/s or 7.6 km/h or 4.7 mph |

Dimensions | 1,360 mm × 910 mm × 300 mm |

Ground Clearance | 30 mm or 1.2 inches |

Running Time | ≥ 11 Hours |

Turning Radius | 0 mm (can rotate in place) |

Charging Time | 3.5 hours (standard) / 1 hour (super charger, 0–100%) |

Safety Features | Emergency button, intelligent LED lights, EN-1525 & CE certified |

AegisLift 2200

Parameter | Specification |

Maximum Payload | 2,000 kg |

Maximum Speed | 2.1 m/s or 7.6 km/h or 4.7 mph |

Dimensions | 1,360 mm × 910 mm × 300 mm |

Ground Clearance | 30 mm or 1.2 inches |

Running Time | Up to 10 hours |

Turning Radius | 0 mm (can rotate in place) |

Charging Time | 3.5 hours (10–100%) / 1 hour (super charger, 10–100%) |

Safety Features | Emergency button, intelligent LED lights, EN-1525 & CE certified |

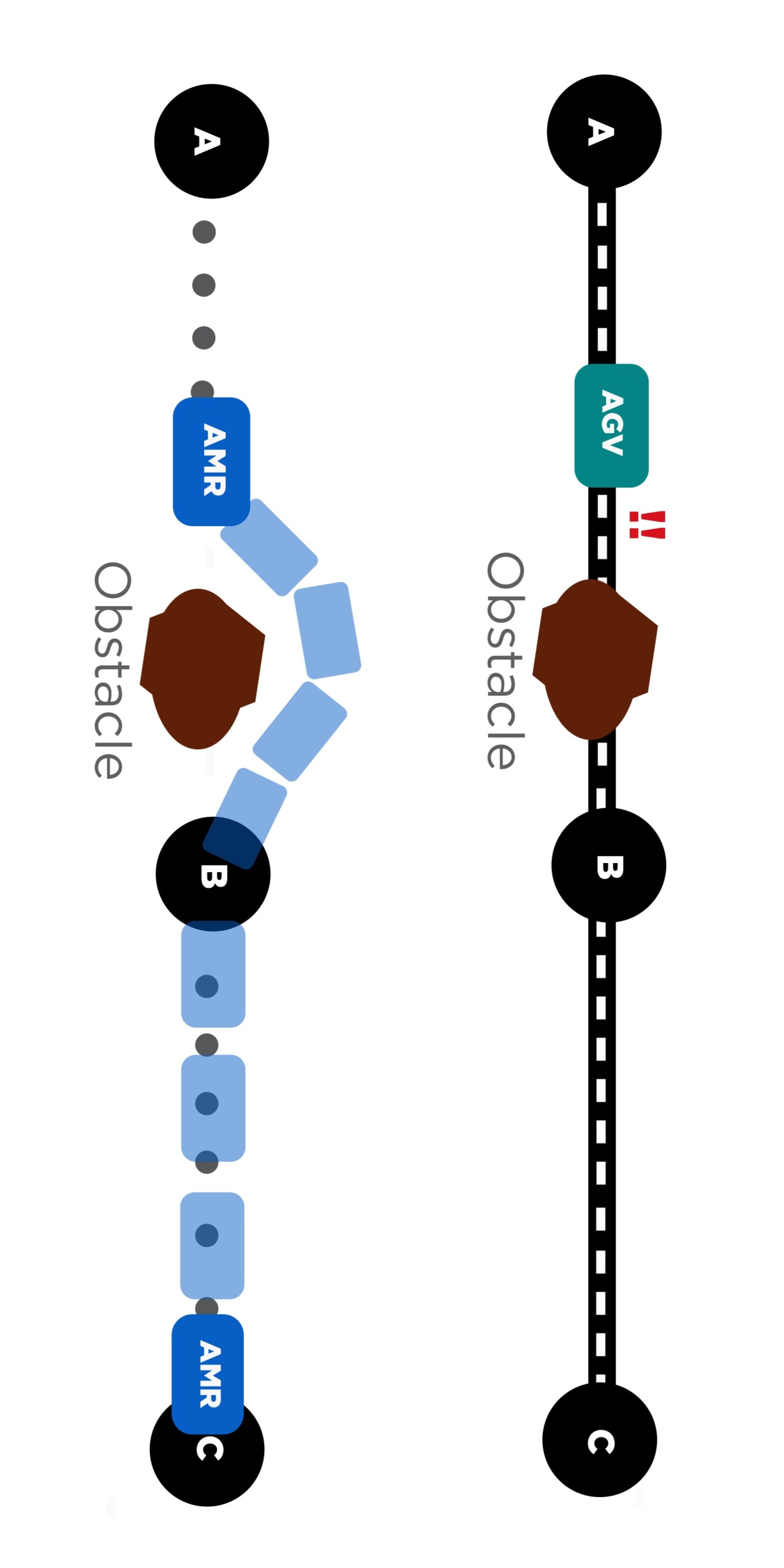

From automated to autonomous: What's the difference?

The words automated and autonomous are often confused or interchanged, but their

meaning is inherently different.

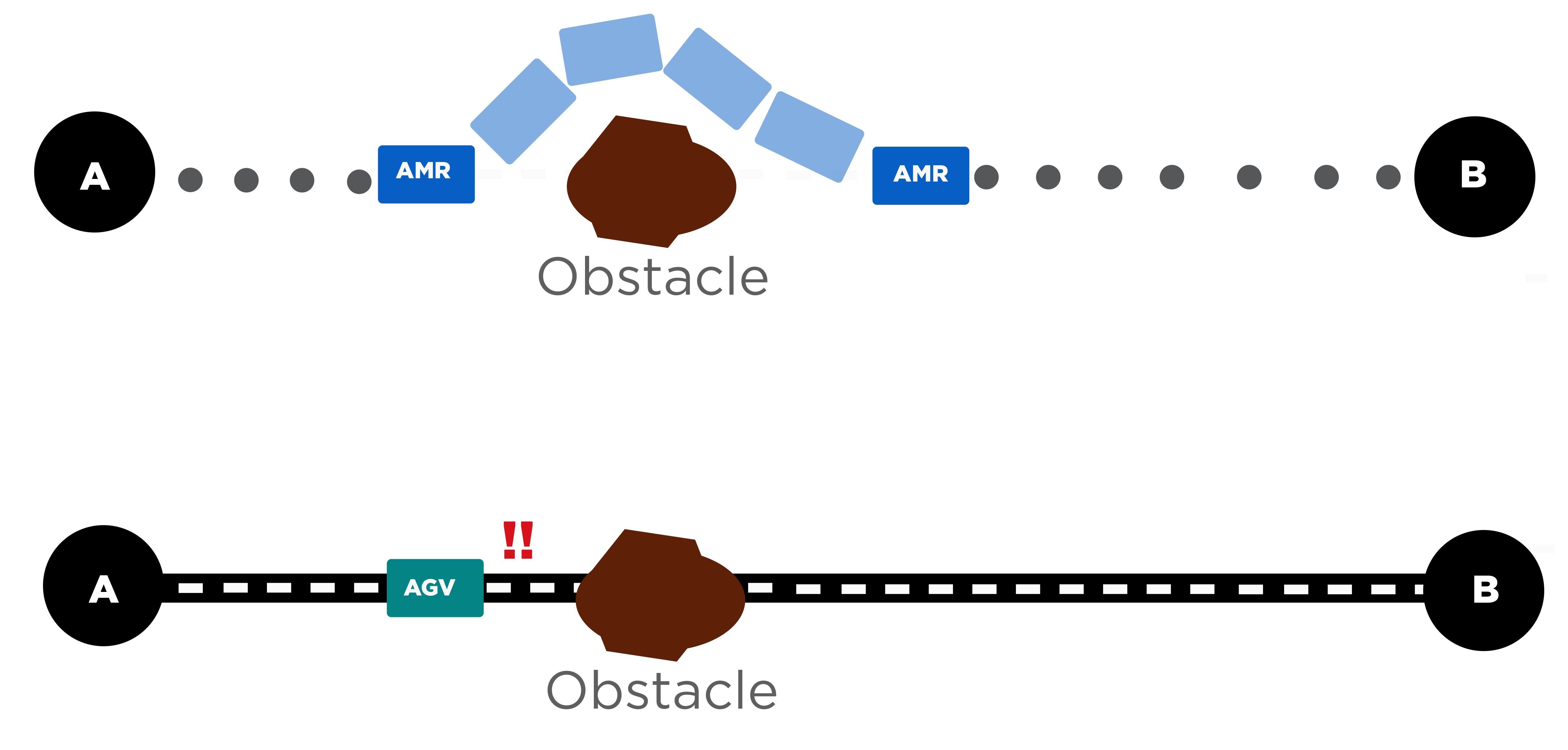

Autonomous:(AMR)

AMRs has the intelligence to make decisions when faced with new or unexpected situations. These robots has the ability to learn as they encounter new scenarios. AMRs are the Self-Drien Robots that can plan, alternate path if it encounter obstacles. lt doesn't require any magnetic tapes or markers.

Automated:(AGV)

An AGV is an unmanned electric vehicle that is controlled by pre.programmed software to move materials around a facility, AGVs rely on guidance devices such as magnetic tape, beacons, barcodes or predefined laser paths that allow the AGw to travel on fixed paths in a controlled space. Lasers and sensors detect obstacles in its path and trigger the vehicle to stop automatically.

AMR VS AGV Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) are also often confused. Each system operates with fundamentally different technology, from perceptionand navigation software to onboard sensors. Therefore, they have different capabilities and potential applications. Autonomous:(AMR) AMRs do notrequire external infrastrcture for navigation, making implementation hassle-free and highly scalable. Impacts:.One AMR unit can be used in multiple applications.Encourages 5S standards for clean aisleways throughout entire facility..AMRs detect, avoid, and dynamically move around obstacles to continue to destination, reducing downtime. Human interaction is not required..Parameters can be customized to navigate through aisleways,personnel zones, and narrow corridors. "AMRs leam which routes are the fastest and take optimal paths, even within unpredictable enironments. Automated:(AGV) AGVs are fixed. They follow predefined paths using lasers. beacons, barcodes or magnetic tape.Impacts:.Multiple AGV units are required for differentapplications..Ongoing infrastructure maintenance is required.Minor debris in the laser's field of view prevents the vehicle from moving until obstacle is manually removed by human personnel.Infrastructure is fixed, changes are rigid and costly..Multiple systems are required in total, despite lowhighseasonal periods.

*AGV's are unable to back up or take alternate routes.

*AGV's cannot easily integrate with other solutions.