Product Description

DE series

Dc servo driver

Fast | Intelligent | Accurate

CANopen bus EtherCAT bus

Functional Features

Digital control and technical features | |

Digital control loop | Current, speed and position, 100% digital loop control; Dual position loop control using the second encoder input |

Sampling frequency (time) | Current loop :15KHZ(66.7μs) Speed/Position loop :3KHZ(330μs) |

Communication | Sinusoidal magnetic field directional control or trapezoidal control from HALL to brushless motors |

Modulation | Space vector PWM modulation with center weighting |

Broadband | The current loop is generally 2.5KHZ and varies with parameter adjustments and load inductance |

HV compensation | Changing the bus voltage (HV) does not affect the bandwidth |

Minimum load inductance | 50 mH wire inductor |

DE Series Technical Specifications |

◆ Control mode: Position, speed, torque; |

Electrical standard specifications | ||||

Position control | Instruction control mode | Servo enable, external reset, forward/reverse limit, motor operation stop, high-speed analog acquisition control, PWM synchronous signal input, high-speed pulse input, etc | ||

Input signal | Pulse instruction | Input pulse pattern | It includes three instruction forms: "direction + pulse", "A and B phase orthogonal pulse", and "CW/CCW pulse" | |

Signal format | Differential input, collector open circuit | |||

Maximum pulse frequency | Differential input :(maximum 2 Mpps) Collector open circuit :(maximum 500Kpps) | |||

Simulation instruction | Voltage range | Input voltage range ±10V | ||

Input impedance | Differential input impedance = 5KΩ | |||

Speed control | Instruction control mode | PWM, ±10V analog quantity, function generator, software programming | ||

Input signal | PWM | Polarity | PWM =0-100%, polarity =1/0 | |

Non-polarity | PWM =50% +/-50% | |||

Frequency range | Minimum 1kHz, maximum 100kHz | |||

Minimum pulse width | 220ns | |||

Simulation instruction | Voltage range | Input voltage range ±10V | ||

Input impedance | Differential input impedance = 5KΩ | |||

Current control | Instruction control mode | PWM, ±10V analog quantity, function generator, software programming | ||

Input signal | PWM | Polarity | PWM =0-100%, polarity =1/0 | |

Non-polarity | PWM = 50% +/-50% | |||

Frequency range | Minimum 1kHz, maximum 100kHz | |||

Minimum pulse width | 220ns | |||

Simulation instruction | Voltage range | Input voltage range ±10V | ||

Input impedance | Differential input impedance = 5KΩ | |||

I/O signal | Digital input IN | The number of ports | 10(Among them, IN6, IN7, IN8, IN9 and IN10 are high-speed ports, and IN5 is internally used for motor temperature protection) | |

Signal format | NPN(Effective at low level) | |||

Settable functions | Servo enable, external reset, forward/reverse limit, motor operation stop, high-speed analog acquisition and control, PWM synchronous signal input, high-speed pulse input, etc | |||

Digital output OUT | The number of ports | 3 | ||

Signal format | NPN(effective at low level), capable of withstands a maximum current of 300 madC and a maximum voltage of 30Vdc | |||

Settable functions | Fault signal, brake control, PWM synchronization signal, custom event, trajectory status, position trigger, program control | |||

Function | LED indication | Status indication, CAN network indication | ||

Communication function | RS-232 | Baud rate | 9600-115200. | |

Agreement | Full-duplex mode, ASCII or binary format | |||

CAN | Baud rate | 20kbit/s-1Mbit/s | ||

Agreement | Canopen Application Layer DS-301V4.02 | |||

Equipment | DSP-402 device drive and motion control | |||

Protection function | Overvoltage, overcurrent, undervoltage, overload, overheating, encoder abnormality, excessive position tracking error and other protections | |||

Usage environment | Installation location | No corrosive gases, flammable gases, etc | ||

Altitude | Less than 1,000 meters | |||

Altitude | -20℃ to +40℃ | |||

Humidity | 5% to 95%RH, no water droplets condense | |||

Vibration resistance/shock resistance strength | Less than 4.9 m/s ² / less than 19.6 m/s ² | |||

Feedback | Digital A/B orthogonal encoder (-E, maximum rate 5M line/s) | |||

Auxiliary encoder input/output (Full closed-loop control /-OP) | ||||

A resolver (-R) is optional | ||||

Digital Hall (-H(U/V/W, 120-degree electrical phase difference)) | ||||

The absolute value encoder (A17) is optional | ||||

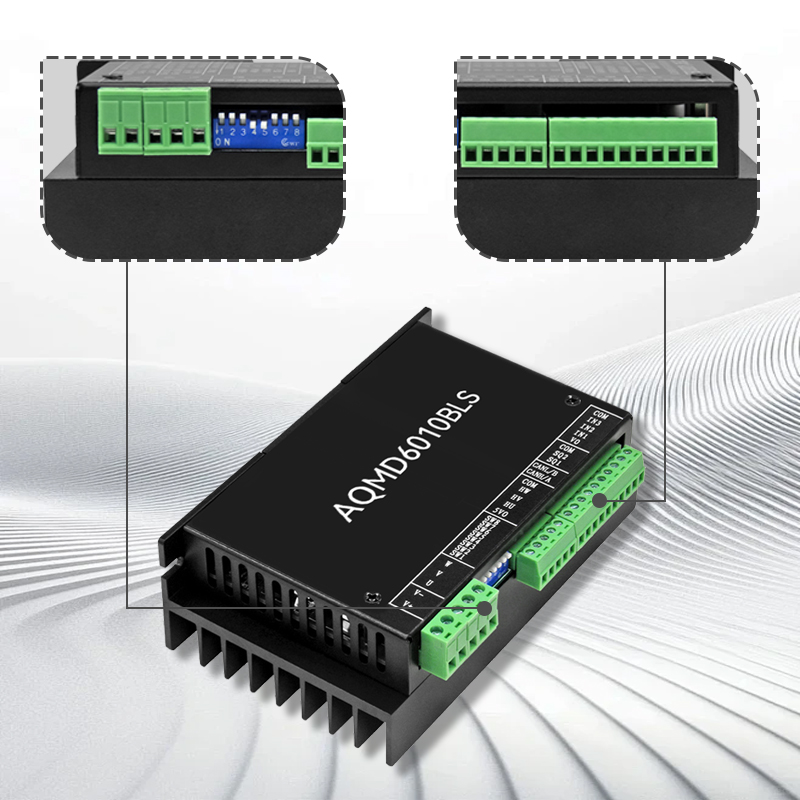

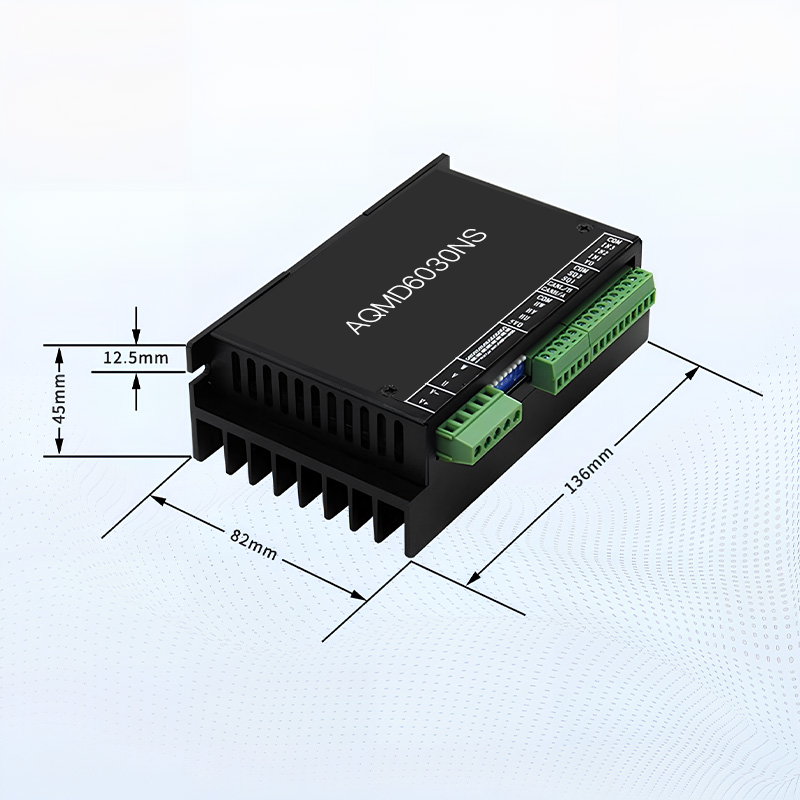

Product Display

REAL PICTURE DETAILS DISPLAY

3A-50A

75A 100A 150A

200A A

300A-MD

300A-LG 350A

Application

Servo drivers are applied in various servo motors, robot fields, new energy fields, automation fields, AGV automotive industries, and control systems. They can convert the input voltage signal into mechanical output on the motor shaft, drive the controlled components, and thereby achieve the control purpose.

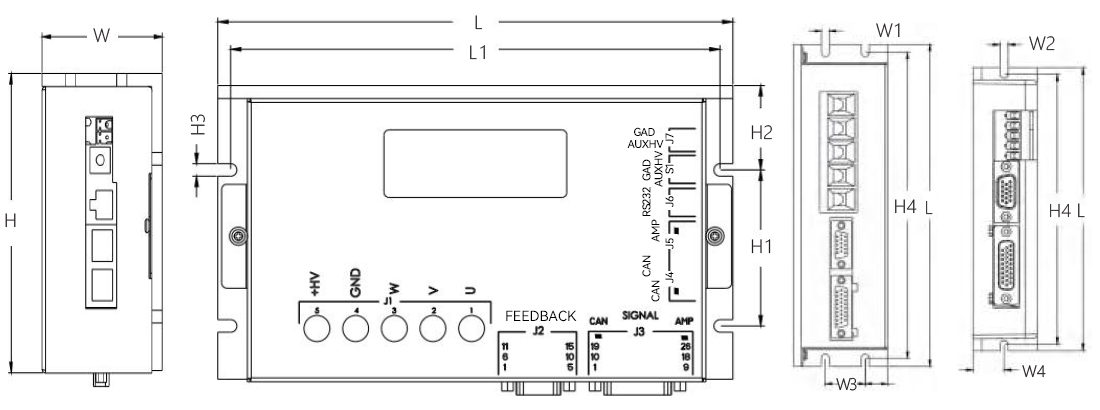

Dimensional drawing

DE series of external dimensions drawings:

Model | L | L1 | W | W1 | W2 | W3 | W4 | H | H1 | H2 | H3 | H4 |

DEPC-3A ~50A | 167 | 160 | 35 | / | 2-4.5 | / | 19. 5 | 100 | 51 | 22 | 4-4.5 | 160 |

DEPC-75A | 200 | 190 | 59 | 4-5.0 | / | 25 | / | 114 | 60 | 32.5 | 4-4.8 | 190 |

DEPC-100A | 200 | 190 | 59 | 4-5.0 | / | 25 | / | 114 | 60 | 32.5 | 4-4.8 | 190 |

DEPC-150A | 221 | 211 | 59 | 5 | / | 25 | / | 140 | 60 | 45 | 4.8 | 211 |

DEPC-200A | 221 | 211 | 85 | 5 | / | 25 | / | 140 | / | / | / | 211 |

DEPC-300A | 221 | 211 | 85 | 5 | / | 25 | / | 140 | / | / | / | 211 |

Model Description

DE | PC | -90 | 16 | -OP | E | MD | |||||||||||||

Series | Special requirements | ||||||||||||||||||

DC/DE/DE2/BC/BC2 | MD: Small size | ||||||||||||||||||

LG: Large size | |||||||||||||||||||

Input instructions | RTR: Reduce temperature rise | ||||||||||||||||||

P:Pulse A:Analog quantity R:RS485 | GT: Green terminal model (BC) | ||||||||||||||||||

C:CANopen E:EtherCAT | |||||||||||||||||||

Feedback | |||||||||||||||||||

Power supply voltage | E: Incremental A/B orthogonal encoder | ||||||||||||||||||

090:18-90VDC 135:18-180VDC | A: Absolute value encoder | ||||||||||||||||||

180:18-180VDC | H: Digital Hall, S: Analog sine and cosine encoder | ||||||||||||||||||

Rated current | Special function | ||||||||||||||||||

16:16Amps(11Arms) 50:50Amps(35Arms) | OP: Pulse output | ||||||||||||||||||

150:150Amps(105Arms) | HUB: Servo hub (BC) | ||||||||||||||||||

Product parameters

Summary table of Driver Specifications | ||||||

Driver model | Power supply voltage | Amps(Arms) | Apk(Arms)6S | Feedback type | External dimensions | Weight |

DEPC-09003-OPEA | 18 ~ 90VDC | 3A(2.1A) | 6A (4.2A) | Incremental or absolute | 167*100*35mm | 0.45kg |

DEPC-09005-OPEA | 5A (3.5A) | 10A(7A) | ||||

DEPC-09010-OPEA | 10A (7A) | 25A(17.5A) | ||||

DEPC-09016-OPEA | 16A(11A) | 48A(33A) | ||||

DEPC-09024-OPEA | 24A(16A) | 50A(35A) | ||||

DEPC-09040-OPEA | 40A(28A) | 80A (56A) | ||||

DEPC-09050-OPEA | 50A(35A) | 100A(70A) | ||||

DEPC-09075-OPEA | 75A(52A) | 150A(105A) | 200*114*59mm | 1.10kg | ||

DEPC-090100-OPEA | 100A(70A) | 200A(140A) | ||||

DEPC-090150-OPEA | 150A (105A) | 250A (175A) | 221*140*59mm | 1.45kg | ||

DEPC-090200-OPEA | 200A(140A) | 300A (210A) | 221*140*85mm | 1.8kg | ||

DEPC-090300-OPEA-MD | 300A(210A) | 420A(294A) | ||||

DEPC-090300-OPEA-LG | 300A(210A) | 420A(294A) | 265*140*85mm | 2.3kg | ||

DEPC-090350-OPEA | 350A(250A) | 465A (330A) | ||||

DEPC-18024-OPEA | 18 ~180VDC | 24A (16A) | 50A (35A) | 167*100*35mm | 0.45kg | |

DEPC-18050-OPEA | 50A (35A) | 100A(70A) | 200*114*59mm | 1.10kg | ||

DEPC-18075-OPEA | 75A(52A) | 150A (105A) | ||||

DEPC-180100-OPEA | 100A(70A) | 200A(140A) | 221*140*59mm | 1.45kg | ||

DEPC-180150-OPEA | 150A(105A) | 250A(175A) | 265*140*85mm | 2.3kg | ||

DEPC-135100-OPEA | 18 ~135VDC | 100A (70A) | 200A (140A) | 221*140*59mm | 1.45kg | |

DEPC-135150-OPEA | 150A (105A) | 250A(175A) | 221*140*85mm | 1.8kg | ||

DEPC-135200-OPEA | 200A(140A) | 300A(210A) | ||||

Note: 1. The supply voltage of the driver must be greater than or equal to the rated voltage of the motor; | ||||||

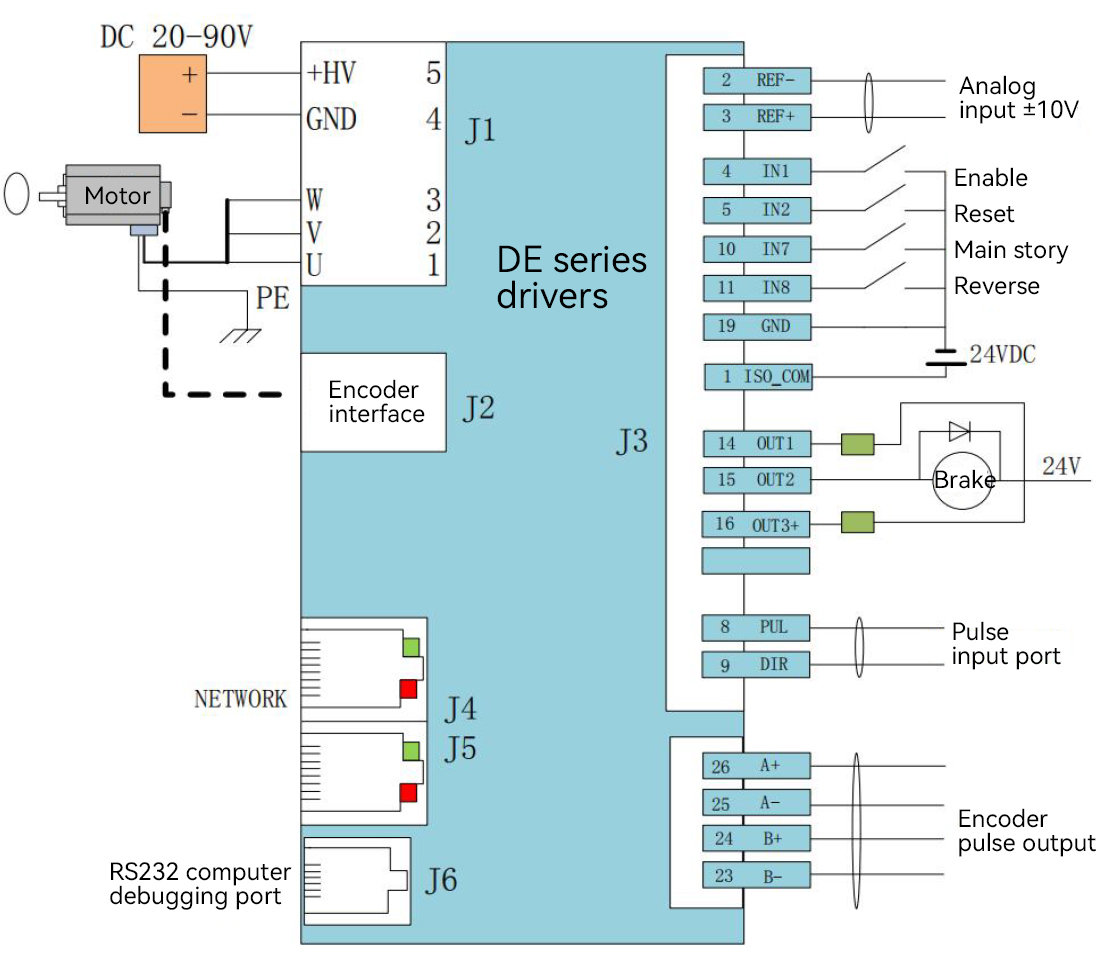

Application wiring diagram

DE series system wiring diagram:

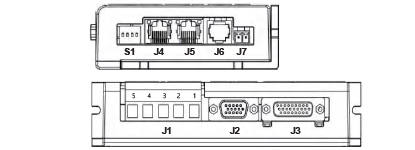

DE series terminal definition

Definition of DE series terminals | |||

J6 RS-232 For debugging | |||

Pin | Definition | Name |

|

2 | RXD | RS232 communication receiving terminal | |

3 | GND | Communication power supply ground | |

5 | TXD | RS232 communication sender | |

J1 motor power supply | J4-J5 CAN communication link | ||||||

Serial number | Definition | Name | Name | Pin | Definition | Name | |

1 | U | Motor power line phase U | It must be connected to the motors one by one according to the labels | 1 | CAN_H | CANH signal | |

2 | V | Phase V of the motor power line | 2 | CAN_L | CANL signal | ||

3 | W | Phase W of the motor power line | +20 ~90V DC | ||||

4 | GND | Input power supply | 3 | GND | Communication power supply ground | ||

5 | +HV | Input power + | |||||

J3 control signal terminal | |||||

Pin | Name | Function | Pin | Name | Function |

1 | ISO_COM | The common terminal of the ISO terminal | 14 | OUT1 | Customize |

2 | Ref- | Analog negative input | 15 | OUT2 | Customize |

3 | Ref+ | Positive input of analog quantity | 16 | OUT3 | Customize |

4 | IN1 | Customize | 17 | MUL_ENC_S- | The second absolute value encoding input |

5 | IN2 | Customize | 18 | MUL_ENC_S+ | The second absolute value encoding input |

6 | IN3 | Customize | 19 | GND | Power supply ground |

7 | IN4 | Customize | 20 | +5V | 5V power output (100mA) |

8 | IN5 | Customize | 21 | EONZ- | The output signal of the motor encoder is Z- |

9 | IN6 | Customize | 22 | EONZ+ | The motor encoder outputs the signal Z+ |

10 | ISO_IN7 | Customize | 23 | EONB- | The motor encoder outputs signal B- |

11 | ISO_IN8 | Customize | 24 | EONB+ | The motor encoder outputs signal B+ |

12 | ISO_IN9 | Customize | 25 | EONA- | The motor encoder outputs signal A- |

13 | ISO_IN10 | Customize | 26 | EONA+ | The motor encoder outputs the signal A+ |

J2 motor encoder feedback | |||||

Pin | Definition | Function | Pin | Definition | Function |

1 | / | / | 9 | W+ | Motor encoder W+ input |

2 | / | / | 10 | ||

3 | U+ | Motor encoder U+ input | 11 | B-(DAT-) | Motor encoder B- input |

4 | +5V | Motor signal line +5V | 12 | B+(DAT+) | Motor encoder B+ input |

5 | 0V | Motor signal line GND | 13 | A- | Motor encoder A- input |

6 | V+ | Motor encoder V+ input | 14 | A+ | Motor encoder A+ input |

7 | Z- | Motor encoder Z-input | 15 | / | / |

8 | Z+ | Motor encoder Z+ input | / | / | / |

The SW dip switch corresponds to the station number | |

SW Switch serial number | Corresponding station number |

1 | 1 |

2 | 2 |

3 | 4 |

4 | 8 |

Service

Dedicated service, along the way

Warranty worry-free, extended repair, often return to promote optimization, peace of mind choice, all in control.

Online customer service Efficient logistics Deliver on time Quality Assurance Technical maintenance Manufacturer support

After-sale guarantee

After-sales service: We provide comprehensive after-sales technical support, if you encounter any problems in the process of use, the professional after-sales engineer team will respond quickly, through telephone, mail or remote assistance, to provide you with detailed solutions. We also provide regular return visits to our products to understand how they are used and to collect your feedback in order to continuously optimize our products and services. In addition, in strict accordance with the quality assurance policy, we provide free repair or replacement services for products with quality problems during the warranty period, so that you have no worries.