Product Description

Metal Surface Finishing

Elegant Appearance · Smooth Surface · Long Service Life

Custom manufacturing available based on customer requirements

| Direct Manufacturer | Custom Production Support | Reliable Quality | Installation Support | Multiple Specifications Available | After-Sales Service |

Our Services

| Core Business | Product surface polishing / Grinding and polishing / Surface sandblasting / Deburring of stamped parts / Mirror polishing /Brushed finishing / Mechanical polishing |

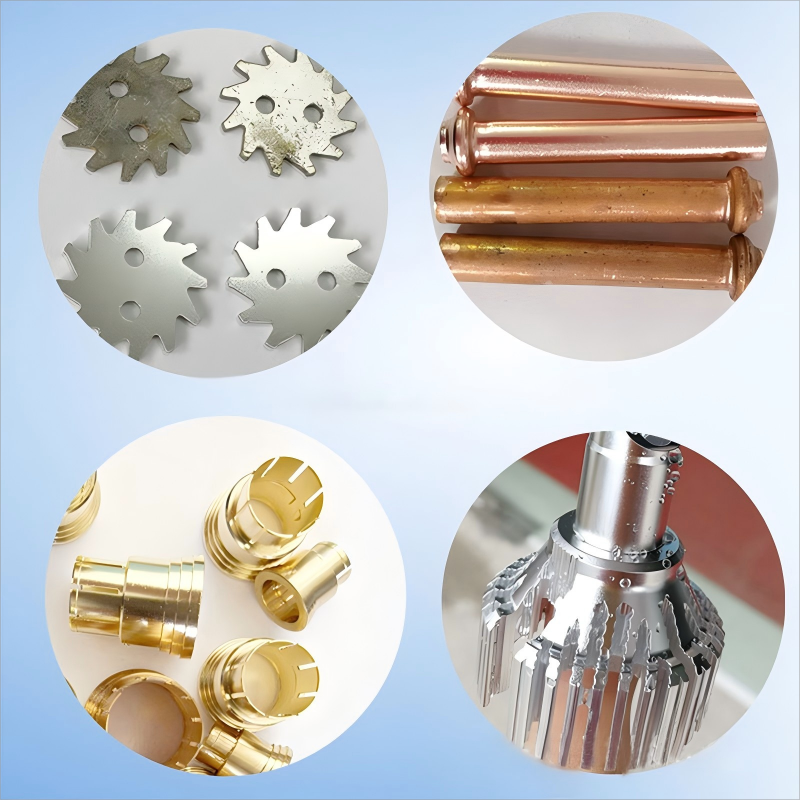

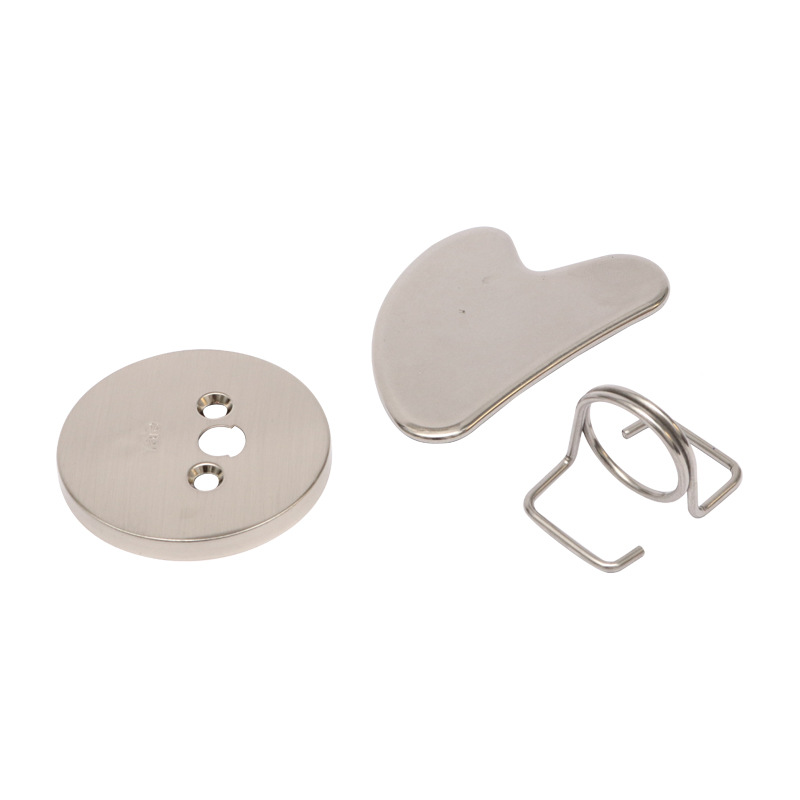

Processing Techniques | Metal components / Hardware parts / Stainless steel / Sapphire / Flat lapping of seals and valve plates / Surface polishing /Double-sided lapping / Double-sided polishing / Mirror finish polishing / Flatness correction / Combined surface and mirror polishing / Surface grinding / End-face polishing / Surface sandblasting / Precision fluid polishing for small components |

Supported Materials | Stainless steel / Alloy steel / Cold-rolled steel / A3 steel / Brass / Sheet metal / Red copper / Low-carbon steel / Zinc alloy / Aluminum alloy / Plastic |

Our Strengths

|

|

|

|

|

|

| Attractive appearance | Smooth surface finish | Fast sample delivery | Supports a wide range of materials | Excellent value for money | Long service life |

Materials

Materials We Can Process

Meeting your diverse custom manufacturing needs

Stainless Steel |

Alloy Steel |

Cold-Rolled Steel |

A3 Steel |

Brass |

Sheet Metal |

Copper |

Low-Carbon Steel |

Zinc Alloy |

Aluminum Alloy |

Processing

Expertise in a wide range of surface finishing techniques

We apply a variety of manufacturing methods to ensure product quality and quantity meet your exact requirements.

Grinding and polishing |

Surface sandblasting |

Mirror polishing |

Brushed finishing |

Examples of Our Processing Techniques

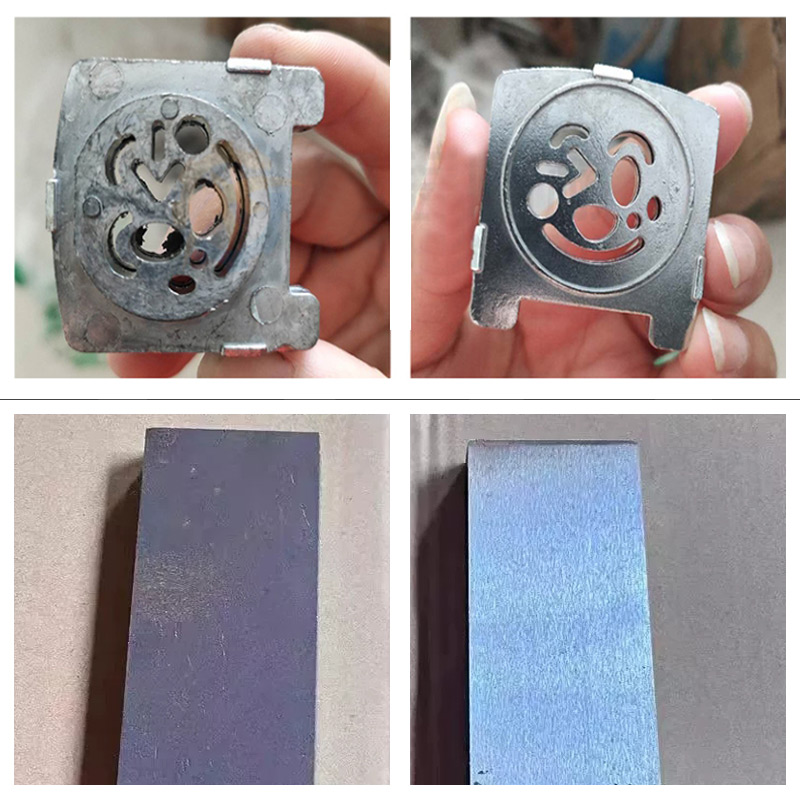

Stainless Steel Polishing Stainless steel tools and components must be corrosion-resistant, visually appealing, and hygienic. human health. Therefore, surface finishing for these products emphasizes the complete removal of harmful materials to ensure both safety and quality. |

Zinc Alloy Polishing This polishing technique is commonly used in precision machinery and optical industries. Polished zinc alloy components feature smooth surfaces and excellent light reflectivity. |

Aluminum Alloy Wire Drawing This process creates a metallic film on the surface that contains components of the alloy itself,revealing fine, linear grain patterns that produce a soft matte finish with a delicate lust. |

Aluminum Alloy Polishing Surface polishing enhances aluminum products with a mirror-like shine, |

Product Display

Applications

|

|

|

|

|

|

Product parameters

Parameter Name | Unit | Parameter Description | Typical Application Scenarios |

Polishing Velocity | m/s (meter per second) | Relative motion speed between polishing tool and workpiece, affecting efficiency and surface quality. Excessive speed may cause overheating, while too low speed reduces efficiency. | Steel polishing: ~25 m/s; Aluminum alloy polishing: 30-50 m/s |

Polishing Force | N (Newton) | Pressure applied by the polishing tool on the workpiece surface. Excessive force causes surface damage, while insufficient force reduces polishing effect. | Precision parts polishing: 5-15 N; Mold polishing: 10-20 N |

Feed Rate | mm/r (millimeter per revolution) | Feed distance per revolution or per minute, determining polishing uniformity and needing to match the polishing velocity. | Injection mold steel grinding: 50 mm/min |

Surface Roughness | μm (micrometer) | Quantitative index of surface micro-irregularities. Smaller Ra value means smoother surface, a core parameter for polishing quality. | High mirror stainless steel: Ra 0.01 μm; General polishing: Ra 0.8 μm |

Abrasive Grain Size | mesh | Thickness of abrasive particles. Larger mesh number means finer particles (suitable for fine polishing), while smaller mesh number means coarser particles (suitable for rough polishing). | Rough polishing: #80-#240 mesh; Fine polishing: #1500-#2000 mesh |

Polishing Time | min (minute) | Duration of polishing treatment, adjusted according to material and roughness requirements. Excessive time may cause over-polishing. | Aluminum alloy small parts: 10-30 min; Large molds: 2-4 h |

Grinding Depth | μm (micrometer) | Depth of grinding tool cutting into the workpiece surface. Larger depth for rough polishing, reduced depth for fine polishing to avoid excessive material removal. | Mold pre-grinding: 20-50 μm; Mirror polishing: <5 μm |

Custom Process

Initial Inquiry

Design Confirmation

Quotation & Pricing

Project Approval

Order Placement

Production Start

Product Delivery

Final Inspection

Equipment

|

|

|

| Roughness Tester Used to measure surface roughness and evaluate smoothness after polishing. | Gloss Meter Used to test surface gloss; commonly available in 60° and 85° measurement angles. | Microscope Used to observe microstructures on the surface, especially for detecting fine defects and surface irregularities. |

|

|

|

|

| Friction and Wear Tester Used to evaluate the wear resistance of polished surfaces and assess long-term performance. | UV-Visible Spectrophotometer (UV-Vis) Used to test surface brightness and gloss using ultraviolet and visible light. | Microhardness Tester Used to measure the hardness of metal surfaces at a microscopic level. | Salt Spray Test Used to assess the corrosion resistance of metal surfaces after polishing. |

Workshop

Service

Introduction to Mechanical Polishing Process

We apply a variety of finishing techniques to ensure that the products we deliver meet both the quality and quantity expectations of our customers.

| Polishing Method | Mechanical polishing removes surface protrusions through cutting and plastic deformation. Common abrasive materials include oilstones,wool wheels, and sandpaper. These are typically operated by hand on dedicated polishing machines, which include an electric motor and 1–2 rotating discs (200–600 rpm) covered with various types of polishing cloth. This method has low cost and simple operation, but lower efficiency, inconsistent results, and limited time control. It is most suitable for polishing small areas. |

| Polishing Process | Rough Polishing abrasives tumble and collide randomly inside the drum. This process removes surface protrusions and reduces roughness, removing approximately 0.01 mm of material. |

Fine Polishing shine. For polishing fine line rulers, the surface is immersed in a slurry made of chromium oxide powder (W5–W0.5) mixed with emulsion. Polishing wheels are made from degreased wood or fine felt. Their movement forms a dense, even mesh pattern. After polishing, surface roughness is ≤ Ra 0.01 µm, with no visible defects under 40× magnification. | |

| Features | - Significant surface smoothing - Reduces surface roughness effectively, resulting in a much smoother surface |

| Limitation | Not ideal for ultra-high precision surface finishing |

| Comparison | Mechanical polishing features simple equipment and ease of use. It supports simultaneous processing of multiple pieces and is suitable for complex shapes. However, it's less effective for large parts or surfaces. |

Guarantee

Product Quality

We have a standardized production line and quality inspection system in place to ensure product quality. Please feel confident when placing your order.

Product Dimensions

Due to manual measurement, slight discrepancies may occur. If you require precise measurements, please consider this before placing an order.

Shipping & Delivery

Actual shipping fees may vary depending on the delivery distance. Please contact us prior to ordering to discuss shipping arrangements. Shipping costs will vary by destination. For details, please consult our online customer service or call us directly.

After-Sales Inspection

Please carefully inspect the product for completeness and condition before signing for receipt.