Product Description

The AXR MPA24A Modular Mold Positioner is a high-precision mold alignment system designed to optimize mold centering and positioning in high-speed, high-accuracy manufacturing environments. Engineered with dual-end precision pins, the MPA24A ensures exceptional repeatability and alignment reliability in cleanroom settings, automotive injection molding, and high-volume metal stamping applications.

Its modular design allows seamless integration with various mold sizes and toolsets, reducing setup time and enhancing production efficiency. Constructed from durable, wear-resistant alloys and treated with anti-corrosion coatings, this positioner guarantees long-term stability, even in intensive production cycles.

Ideal for use in medical device manufacturing, automotive part molding, and precision die operations, the MPA24A provides manufacturers with the confidence of perfect mold engagement, reduced maintenance needs, and superior process control.

Product Features

Wide Adjustable Stroke (110 mm)

Capable of handling a wide range of part sizes without the need to change fingers, increasing operational versatility.

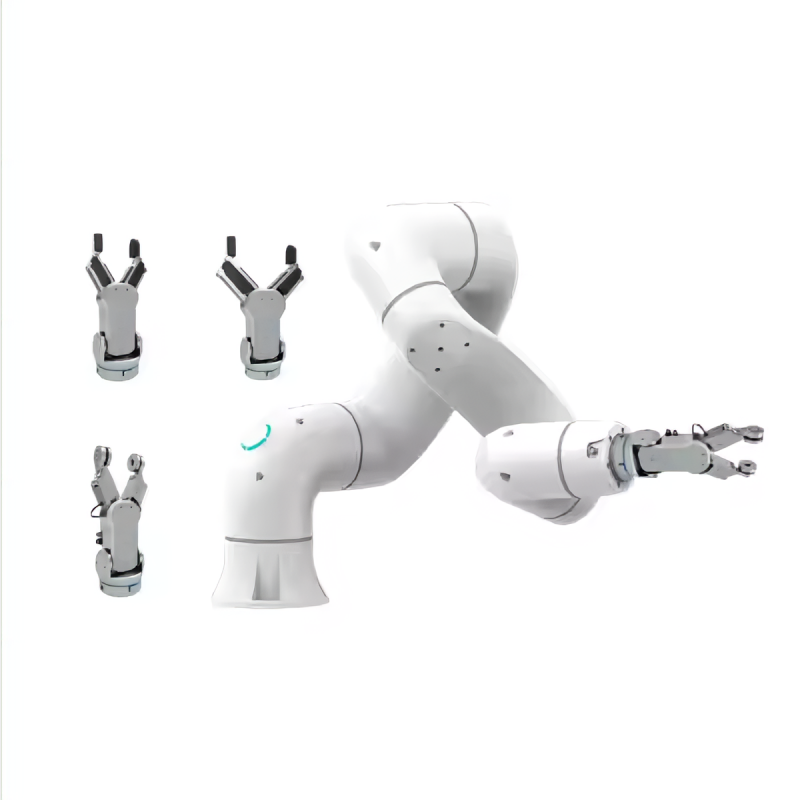

Plug & Produce Integration

Seamlessly integrates with collaborative robots (Cobots) such as UR, Han’s Elfin, Aubo, and others with minimal setup time.

Built-in Proximity Sensors

Includes internal sensors to detect object presence and adjust gripping force for enhanced safety and precision.

Lightweight and Compact Design

Compact form factor and lightweight construction make it ideal for payload-limited robotic arms.

Flexible and Customizable Fingers

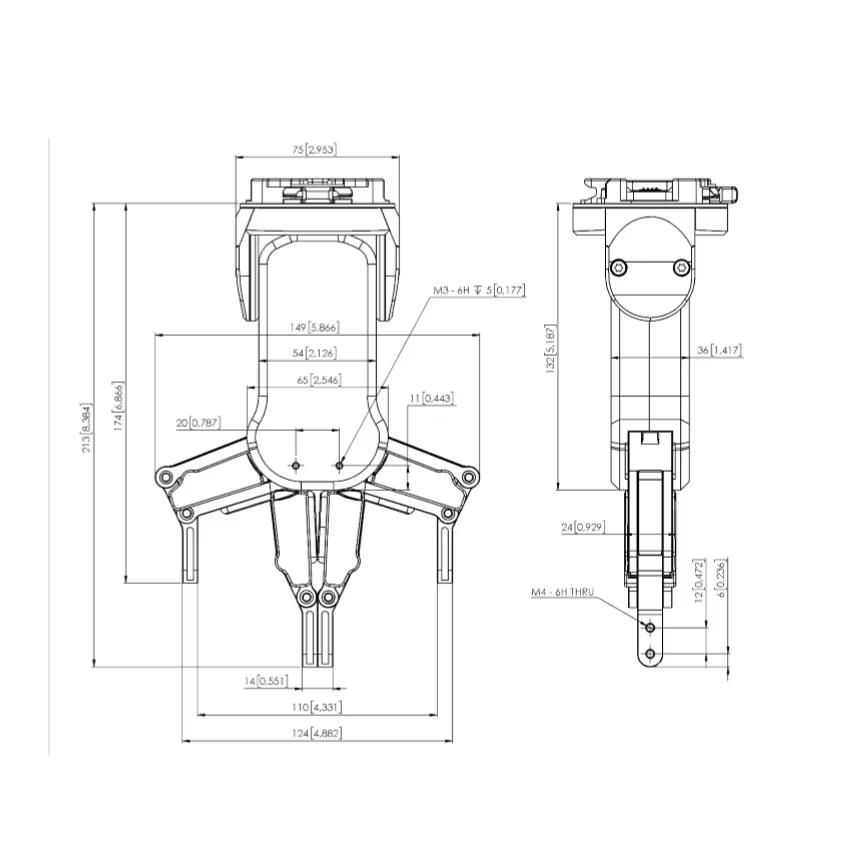

Finger pads can be customized or modified to securely grip various shapes and delicate parts.Structure Diagram

Product parameters

Payload Force Fit | 2kg/5kg |

Total stroke | 110mm |

Repetition accuracy | 0.1-0.2mm |

Gripping speed | 38-127 mm/s |

Dimensions | 213 x 149 x 36 |

Weight | 0.78 |

Customer Case

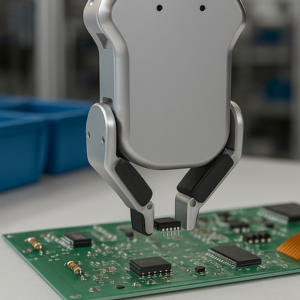

Precision Electronics Assembly – Electronics Manufacturing

Customer: PCB Assembly Plant

Application: The RG2 gripper is used to pick and place small electronic components such as resistors, IC chips, and ribbon cables with delicate handling.

Outcome: Reduced damage rate by 25% and increased production speed by 40%.

Packaging Automation – Food and Beverage Industry

Customer: Leading Snack Manufacturer

Application: The RG2 gripper handles lightweight packaged goods (e.g., snack pouches) and places them into shipping boxes or trays.

Outcome: Minimized manual labor in packaging and reduced downtime when switching between package sizes.

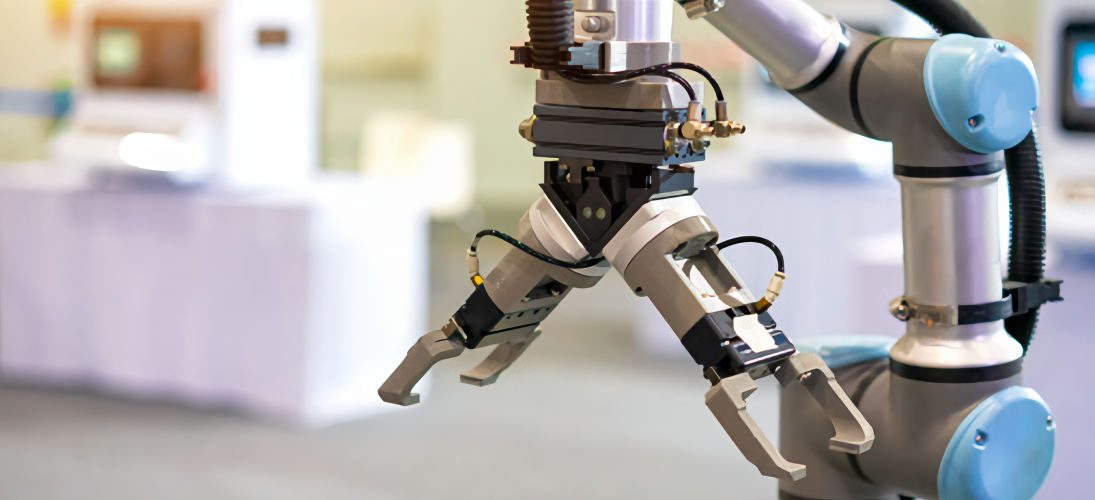

CNC Machine Tending – Precision Metalworking

Customer: Automotive Parts Machine Shop

Application: The gripper loads and unloads metal parts to and from CNC machines with high precision and reliability.

Outcome: Improved production efficiency by 35% and enabled unattended night shifts with reduced labor costs.