Product Description

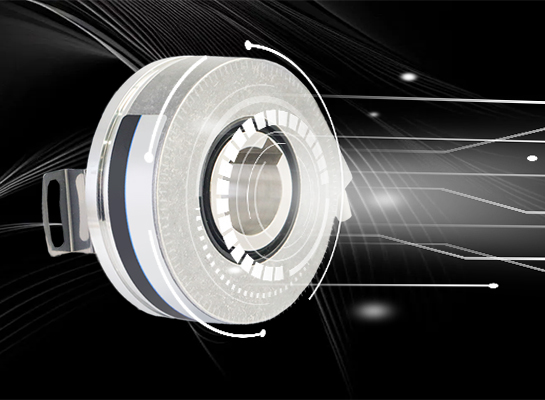

KC76 incremental photoelectric encoder is a through-hole encoder with keyway that can output incremental and UVW signals. It has a compact and durable structure and is widely used in servo motors and industrial automation

Product features: |

|

Product parameters

Project | Basic parameters | |

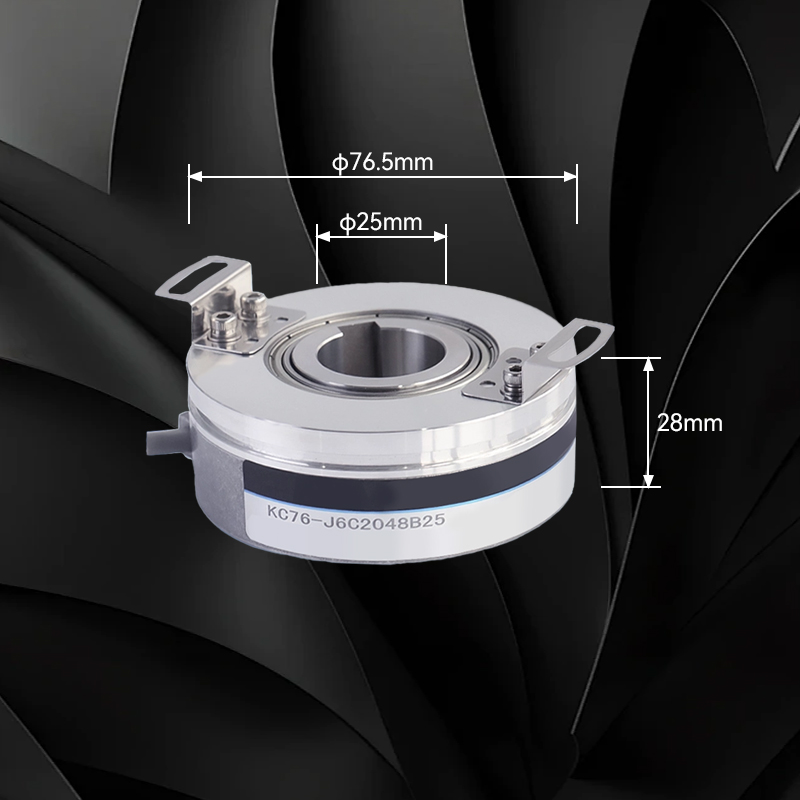

Dimensions | Outer diameter:76.5mm | |

Thickness:28mm | ||

Shaft diameter: 6mm/8mm/10mm | ||

Pulse | 100;200;250;256;360;500;512;600;512;600;700;800;900;1000;1024;1200;2000;2048;2500;3000; | |

Output phase | Phase A,B,Z A -B- Z- | |

Power supply voltage | DC5V & DC8-30V | |

Output mode | Cable side outlet | |

Output type | NPN open collector output | |

Voltage output | ||

Push-pull output | ||

Differential output | Long line driver (26LS31) | |

Compatible with RS422 | ||

Long line driver (RT7272) | ||

Ambient temperature | Working temperature: -20~+80° (non-condensing) | |

Storage temperature: -25~+85° (non-condensing) | ||

Ambient humidity | Working and storage: 35~85%RH (non-condensing) | |

Protection level | IP50 | |

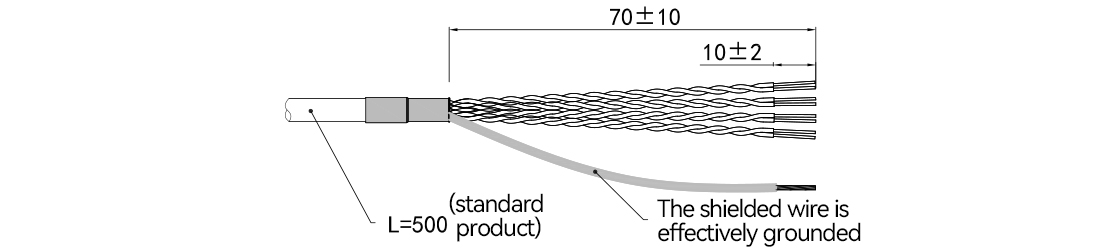

Line length | 1M(The cable length can be extended according to customer requirements) | |

Casing | Die-cast aluminum alloy | |

Packing method | Paper Box | |

Weight | 350g | |

Certificate | CE | |

Instructions

1. Selection guide

Model composition (selection parameters)

KC76- | J | 6 | C | 1024 | B25 | - | 000 | |||||||||

↑ | ↑ | ↑ | ↑ | ↑ | ↑ | ↑ | ↑ | ↑ | ||||||||

Series | Connection interface: |

| Electrical interface: | Resolution PPR:

| Shaft diameter: | Supply voltage: H=DC8-30V | Special requirement: | Management |

Notes:

①Z phase signal is valid at low level.

②Z phase signal is valid at high level.

③None means IP50, cable length is 1M, if you need to change the length, C+number, the maximum length is 100M (indicated by C100)

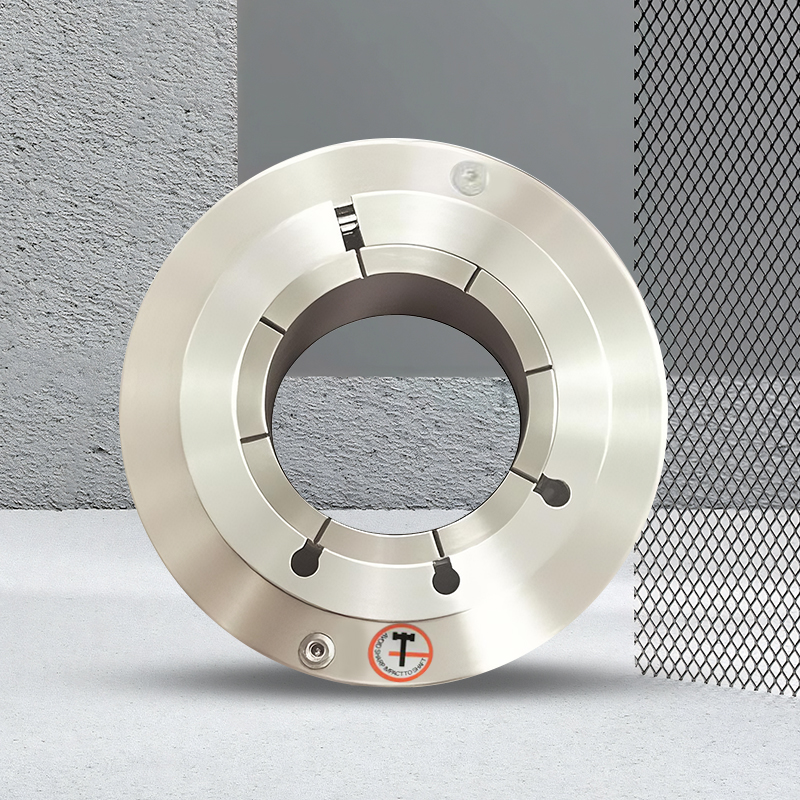

2. Output mode

2.1 Incremental signal

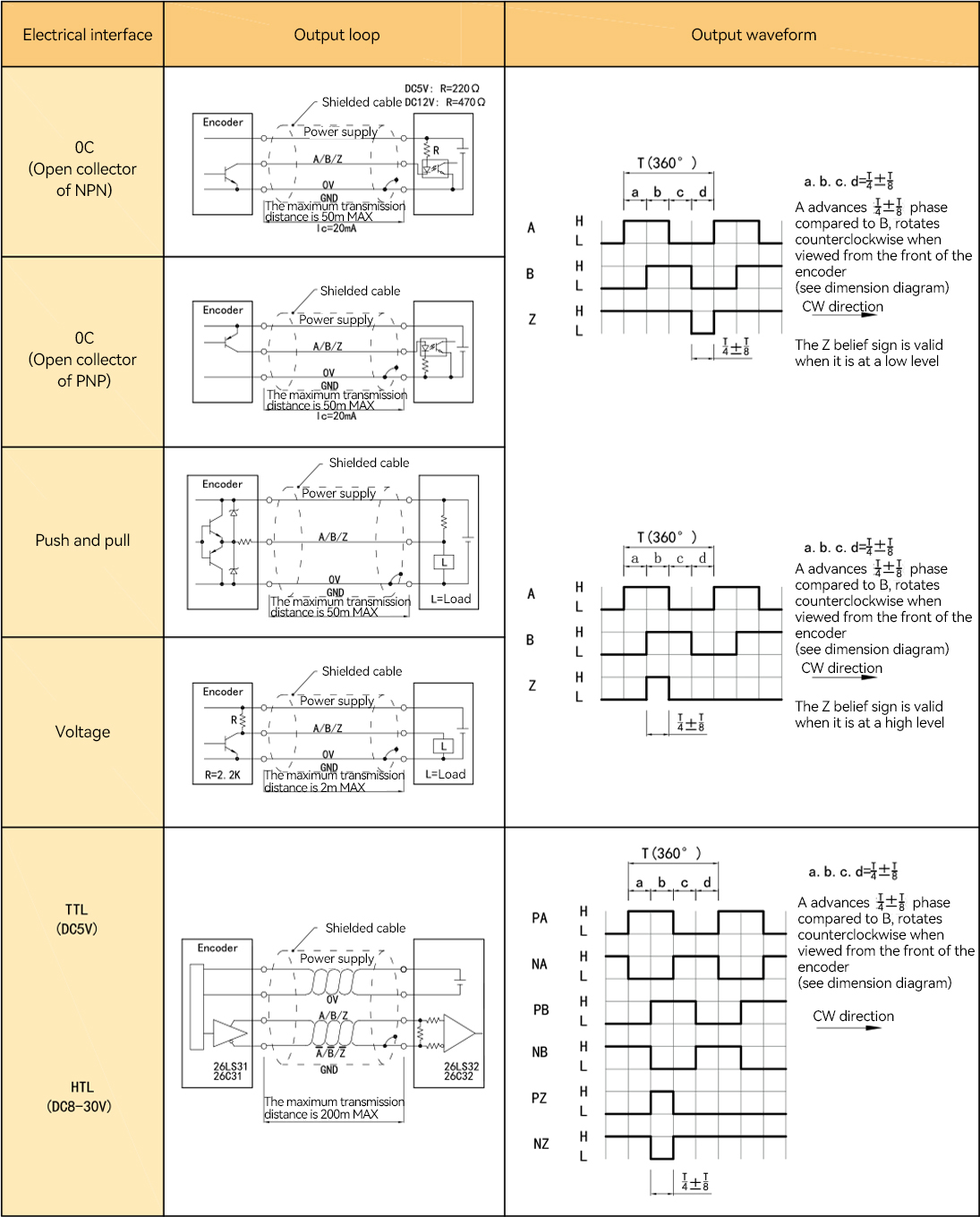

2.2 Dedicated to servo motor (with U.V.W)

3. Electrical parameters

Project | Output method | ||||||

OC | Voltage | Push-pull | TTL | HTL | |||

Supply voltage | DC+5V±5% ; DC8-30V±5% | DC+5V±5% | DC8-30V±5% | ||||

Current consumption | 100mA Max | 120mA Max | |||||

Allowable ripple | ≤3% rms | ||||||

Maximum response frequency | 100KHz | 300KHz | 500KHz | ||||

Output capacity | Output | Inflow | ≤30mA | Load resistance 2.2K | ≤30mA | ≤±20mA | ≤±50mA |

Outflow | — | ≤10mA | |||||

Output | "H" | — | — | ≥[(power supply voltage)-2.5V] | ≥2.5V | ≥Vcc-3 VDC | |

"L" | ≤0.4V | ≤0.7V(20mA or less) | ≤0.4V(30mA) | ≤0.5V | ≤1 VDC | ||

Load voltage | ≤DC30V | — | — | ||||

Rise and fall time | 2us or less (wire length: 2m) | ≤100ns 1μs or less (wire length: 2m) | ≤100ns | ||||

Insulation withstand voltage | AC500V/60s | ||||||

Insulation impedance | 10MΩ | ||||||

Duty cycle | 45%~55% | ||||||

Reverse polarity protection | ✔ | ||||||

Short circuit protection | — | ✔① | |||||

A.B Phase Difference | 90°±10° (at low frequency) | ||||||

90°±20° (at high frequency)) | |||||||

Shielded wire | Encoder body not connected | ||||||

Note: ① Short circuit with another cable or GND, the maximum allowed time is 30 seconds | |||||||

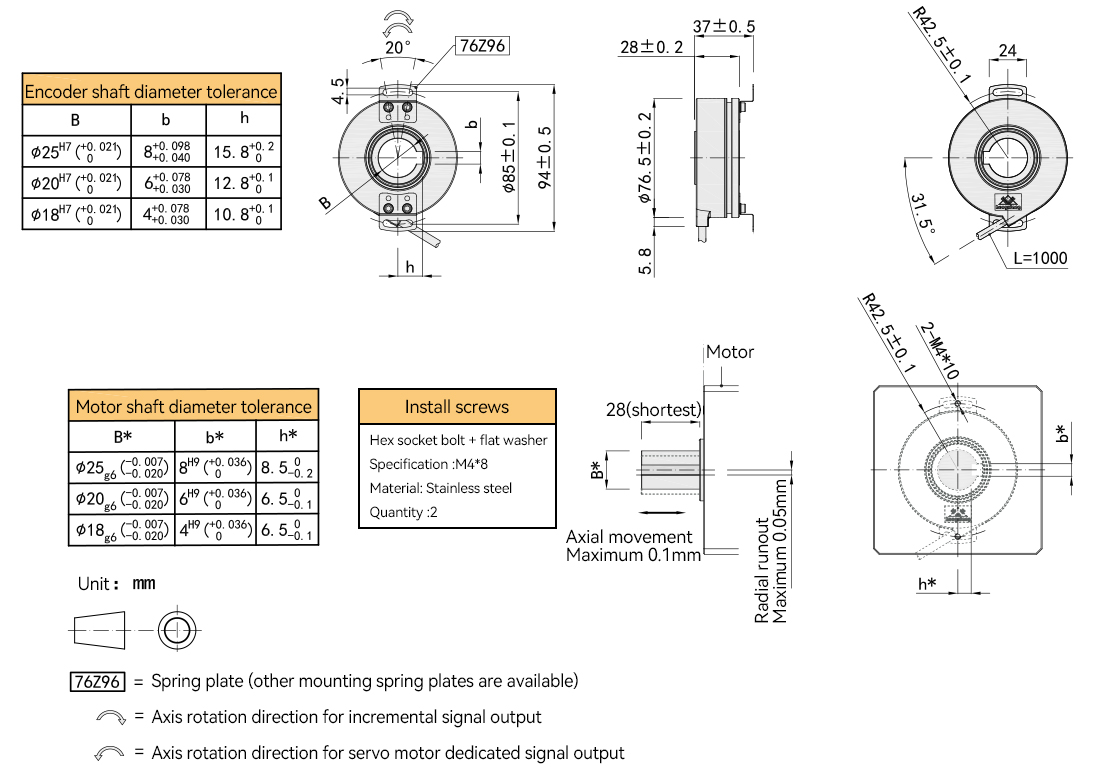

4. Mechanical specifications

Project | Parameter |

Shaft diameter | Φ18mm、Φ20mm、Φ25mm (optional) |

Shaft material | Stainless steel |

Starting torque | 80×10⁻³ N・m or less |

Moment of inertia | 100×10⁻⁶ kg・m² or less |

Allowable static shaft displacement | ±0.2mm (radial); ±0.3mm (axial) |

Allowable dynamic shaft displacement | ±0.05mm (radial); ±0.1mm (axial) |

Allowable shaft force | Radial 70N; Axial 50N |

Maximum allowable speed |

|

Housing | Die-cast aluminum alloy |

Weight | Approx. 200g |

5. Environmental parameters

Project | Parameter |

Enclosure protection grade | IP50 |

Permitted relative humidity | During operation, during storage: 35~85%RH (no condensation) |

Operating temperature range | During operation: -20~+85℃ (repeated bending of cable: -10℃℃) |

Storage temperature range | During storage: -25~+90℃ |

Shock resistance | 1960m/s², 11ms 3 times in each direction of X, Y, Z |

Frequency range of vibration resistance | Amplitude 0.75mm, 5~55HZ, 2h in each direction of three axes |

6. Wiring table

6.1 OC/voltage/push-pull

Supply voltage | Incremental signal | ||||

Line color | Red | Black | White | Green | Yellow |

Function | Up | OV | A | B | Z |

6.2 TTL/HTL

Supply voltage | Incremental signal | |||||||

Line color | Red | Black | White | White / Black | Green | Green/Black | Yellow | Yellow/Black |

Function | Up | OV | A+ | A- | B+ | B- | Z+ | Z- |

Twisted Pair | |  |  |  | ||||

6.3 Servo motor only

Supply | Incremental signal | |||||||||||||

Line color | Red | Black | White | White / | Green | Green/ | Yellow | Yellow/ | Blue | Blue/ | Gray | Gray/ | Pink | Pink/ |

Function | Up | OV | A+ | A- | B+ | B- | Z+ | Z- | U+ | U- | V+ | V- | W+ | W- |

Twisted Pair |  |  |  |  |  |  |  | |||||||

Up = power supply voltage.

The shielded wire is not connected to the internal circuit of the encoder.

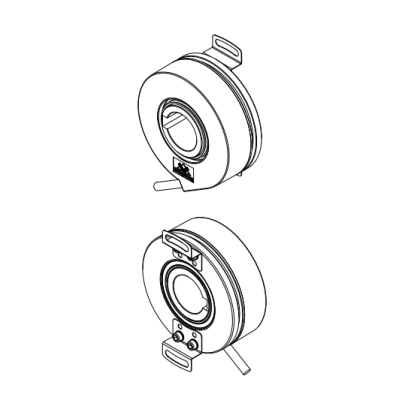

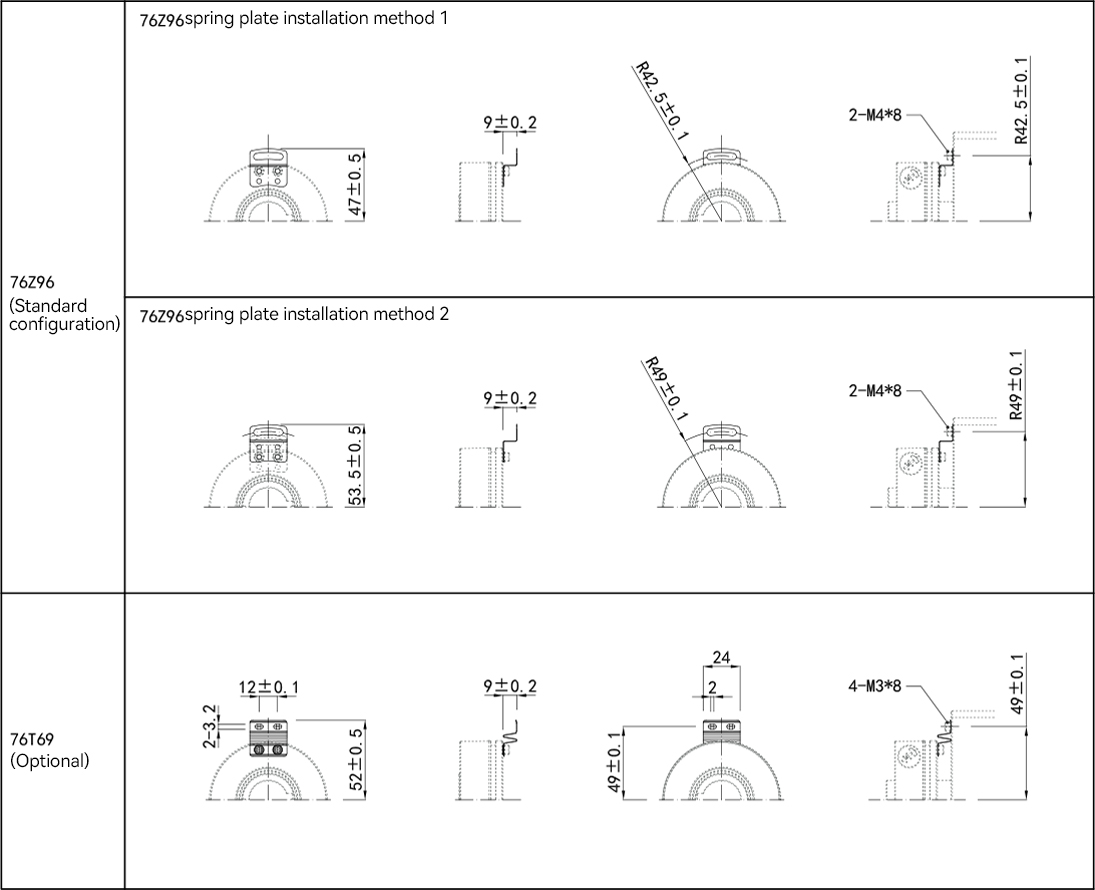

7. Basic dimensions and installation requirements

8. Accessories (spring plate optional)

Product Display

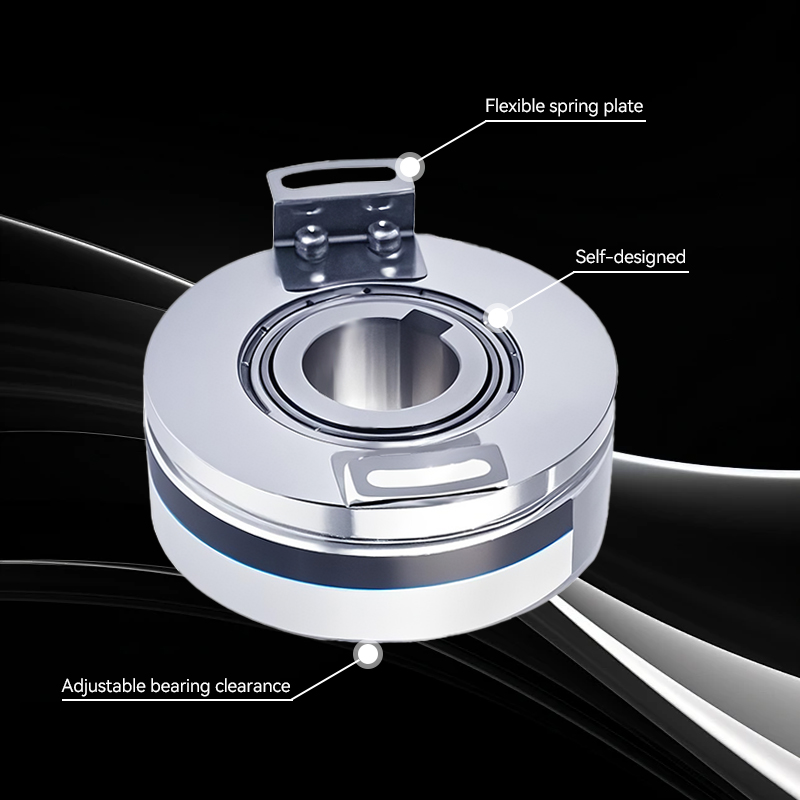

Through-shaft keyway design: shaft diameter up to 25mm, keyway installation, stable connection

High resolution: up to 65536PPR, accurate feedback of position and speed

Compact and durable structure: 76.5mm diameter, die-cast aluminum alloy housing, suitable for industrial environment

High speed tolerance: allows up to 3000rpm, meeting dynamic control needs

Multiple electrical interfaces: adapt to different control systems, strong compatibility

Protection and protection: reverse polarity, short circuit protection, improve system reliability

Anti-interference ability: non-contact photoelectric principle, reduce mechanical wear and interference

Quality Control

The quality of encoders is directly related to the stability and reliability of industrial automation systems. We have built a full-process quality control system, strictly screening suppliers from raw material procurement to ensure that the performance of core components meets standards; in the production process, we use high-precision equipment and standardized processes, and cooperate with online detection technology for real-time monitoring; in the finished product stage, we conduct rigorous tests such as high and low temperature, electromagnetic compatibility, and life aging to eliminate performance risks. Each encoder has passed multiple quality inspection levels, and its excellent quality has laid a solid foundation for intelligent manufacturing, providing customers with long-term and stable use guarantees.

Application Cases

With its through-shaft keyway design (maximum shaft diameter 25mm) and high resolution (up to 65536PPR), the KC76 series encoders achieve precise angle feedback through non-contact photoelectric principles in the servo motor field and support motor closed-loop control. In subway and elevator scenarios, reverse polarity/short-circuit protection improves system reliability, and keyway connection ensures stable installation. In the CNC field, a variety of electrical interfaces are compatible with different controllers, and the compact structure and high speed tolerance (≤3000rpm) meet the high-precision processing requirements of machine tools.

Service

I. Precautions for using the encoder

Places where the ambient temperature does not exceed the storage temperature; places where the relative humidity does not exceed the storage humidity; places where the temperature changes sharply and fogging occurs; places close to corrosive gases and flammable gases; places away from dust, salt, and metal powder; places where water, oil, and medicines are used; places where excessive vibration and impact will be transmitted to the body

II. Precautions for installing the encoder

Electrical components must not be subjected to overvoltage and other phenomena. Please conduct an electrostatic assessment of the setting environment, etc. Do not bring the motor power line close to the encoder; the FG line of the motor and the FG of the mechanical device must be reliably grounded; due to shielding The wire is not connected to the encoder body. Please make sure that the shielded wire is effectively connected to the ground at the user end.

III. Precautions on wiring

When used under the specified power supply voltage, please pay attention to the power supply voltage amplitude drop caused by the long wiring; please do not use the encoder wire and other power wires in the same pipe or bundle them in parallel; please use twisted pair wires for the signal wire and power wire of the encoder wire; please do not apply excessive force to the encoder harness, there will be a risk of disconnection

IV. About encoder warranty

Within twelve months after purchasing our company's products, users can get free warranty when they use them correctly according to the instructions,warning signs and other precautions and cause failures.

The following situations will be charged even during the warranty period: (freight is at your own expense)

1. Failures and damages caused by the user falling to the ground during transportation and handling, improper installation;

2. Failures of this product caused by the machine connected to it;

3. Failures and damages caused by fire, salt water, corrosive gas, abnormal voltage and other natural disasters such as earthquakes, thunder, wind, floods, etc.;

4. Repairs, adjustments, and modifications without the permission of our company (labels are not there or the outer cover is disassembled by yourself).

5. Failures that occur when the product is not used in accordance with the instructions and precautions in the instruction manual.

6. Except when other agreements are signed with the customer.