Product Description

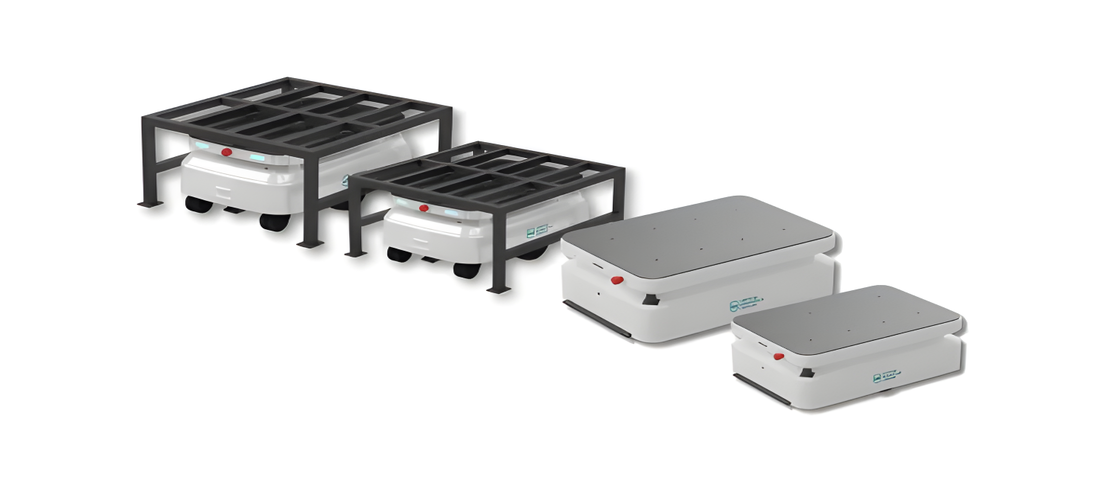

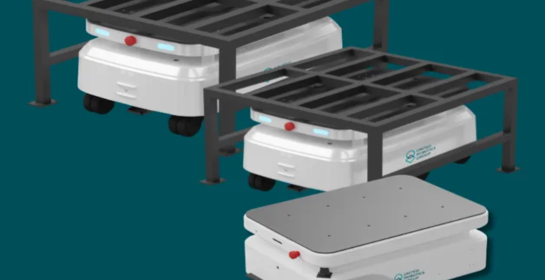

Introducing LiftDrive 300, the advanced autonomous mobile platform engineered for high-load logistics across manufacturing, warehousing, and smart facility operations. Building on the proven success of under-shelf transport systems, LiftDrive 300 offers double the payload capacity, faster charging, and superior navigation intelligence.

With a compact and low-profile design, LiftDrive 300 can seamlessly slide under standardized racks, carts, and pallets to lift and move them autonomously. Designed for easy integration into existing workflows, it eliminates the need for costly infrastructure changes, significantly boosting efficiency, throughput, and labor optimization.

Whether you're optimizing internal logistics in a factory or automating transport in a smart warehouse, LiftDrive 300 is the powerhouse platform you can count on.

Applications

| Industry | Use Case |

| Manufacturing | Raw material delivery, component transfer between stations |

| Warehousing | Autonomous pallet/rack movement, order fulfillment |

| Retail | Stockroom replenishment, in-store restocking |

| Healthcare | Transport of medical carts or heavy equipment |

| Logistics Hubs | Parcel movement, zone-to-zone delivery |

Product Features

PowerLift™ Load System (300kg Capacity)

Equipped with a precision-engineered hydraulic lift system, the PowerLift™ mechanism allows LiftDrive 300 to autonomously raise and transport carts, shelves, or pallets weighing up to 300 kg, doubling traditional capacity while maintaining stability and maneuverability.

AutoNav™ SLAM Navigation with FleetSync™ Integration

Utilizing real-time SLAM (Simultaneous Localization and Mapping), LIDAR, and 360° obstacle detection, LiftDrive 300 accurately maps environments and makes dynamic route adjustments. FleetSync™ allows multiple robots to coordinate efficiently without interference, ideal for large-scale operations.

Structure Diagram

Product parameters

| Specification | Details |

| Dimensions | 900mm (L) x 650mm (W) x 280mm (H) |

| Weight | 85 kg |

| Payload Capacity | 300 kg |

| Platform Height (Lifted) | 400 mm |

| Drive Speed | Up to 1.2 m/s (configurable) |

| Battery Life | 10 – 12 hours (typical operation) |

| Charging Time | 1 hour (fast charge) |

| Navigation System | LIDAR + SLAM + IMU + UWB |

| Connectivity | Wi-Fi 6, 4G/5G ready |

| Safety Compliance | CE, ISO 3691-4, EN1525 |

Customer Case

Hospital

Office

Industry

FAQ

Q: What types of platforms or carts are compatible with LiftDrive 300?

A: It can work with most standard shelves, trolleys, and carts designed with bottom clearance. Custom adapters are available for non-standard bases.Q: Can LiftDrive 300 operate in multi-floor facilities?

A: Yes, it supports elevator integration and can be coordinated to move between floors using building APIs.Q: Is there a need for floor markers or QR codes?

A: No. The AutoNav™ SLAM system uses vision and LIDAR for navigation without requiring fixed infrastructure.Q: Can it operate in mixed traffic environments with people and forklifts?

A: Absolutely. LiftDrive 300 includes multi-sensor obstacle avoidance and dynamic path adjustment for safe operation in human environments.Q: What happens when the battery is low?

A: The robot autonomously returns to its charging dock and resumes tasks once sufficiently charged.