Product Description

The Picknex iArm-600 is a next-generation 6-axis CNC robotic manipulator engineered for high-precision, flexible, and intelligent automation across a wide range of industrial applications. Designed with advanced kinematics, AI-assisted control systems, and seamless CNC integration, the iArm-600 is built to meet the demands of smart factories and high-performance manufacturing environments.

Key Features

6-Axis Articulated Design

Enables complex, multi-directional movement with high repeatability for tasks such as assembly, welding, material handling, and pick-and-place.

CNC-Compatible Control System

Fully integrated with CNC platforms for synchronized operations in automated production lines.

Intelligent Motion Planning

Equipped with real-time adaptive path planning, obstacle avoidance, and AI-powered task optimization.

High Payload & Precision

Supports up to [XX kg]* payload with repeatability up to ±0.02 mm, ideal for both heavy-duty and fine-detail industrial tasks.

Modular Interface & I/O Integration

Compatible with a variety of end-effectors (grippers, welders, cameras) and ready to integrate with PLCs, HMIs, SCADA, and IoT systems.

Smart Diagnostics & Remote Monitoring

Built-in sensors, condition monitoring, and cloud-based maintenance analytics enable predictive service planning and reduced downtime.

Applications

· Automotive and aerospace assembly

· Electronics precision handling

· CNC machine tending

· Welding, cutting, and polishing

· Packaging, palletizing, and logistics automation

· Food and pharmaceutical processing

Why Choose iArm-600?

With its robust construction, intelligent control, and Industry 4.0 readiness, the Picknex iArm-600 empowers manufacturers to scale productivity, enhance quality, and reduce operational costs—making it a powerful tool for the future of automation.

Product Features

1. High reliability

The machine has excellent carrying quality, speed,allowable torque of thewrist axis, etc.in the same class, and strong carrying capacity

2. Compact structure

Compact structure The hollow arm structure with built-in cables is adopted to reduce movement restrictions due to cable interference

3. high working efficiency

By improving the acceleration and deceleration control, there is no need to rely on the posture,the acceleration and deceleration time is shortened, and the production efficiency is improved.

4. Simple maintenance

The original point data can be maintained without connecting the battery when replacing theinternal cable. Reduce the number of cables and connectors to improve work performance

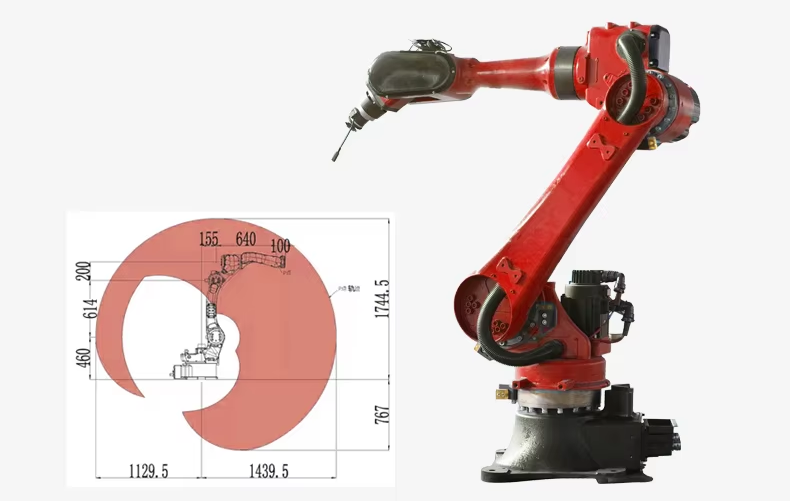

Structure Diagram

Product parameters

Item | Specification |

Model | GC1610 |

Load Capacity | 10 KG |

Structure Type | Vertical multi-joint type |

Power Consumption | 4.5 kVA |

Repeat Positioning Accuracy | ±0.05 mm |

Scope of Work | Contact Sales |

Speed | Contact Sales |

Robot Weight | 180 KG |

Installation Method | Ground rail / Upside down / Gantry / Wall-mounted |

Protection Grade | IP56 / IP67 |

Service

|

| |

High level of control | High precision | Strong structure |

|

|

|

Low noise level | work widely | long lifetime |

SHIPMENT

If you need any favorable or fastshipping welcome to contact us.