Product Description

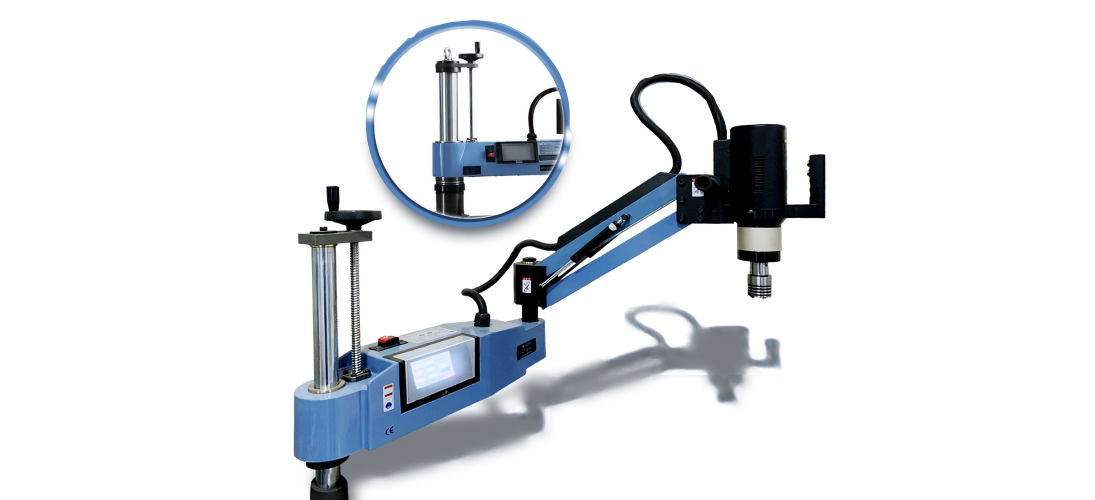

The SFX M36R is a high-precision electric tapping machine designed for efficient threading, drilling, and tapping operations. Featuring a 360-degree flexible arm, it supports thread sizes from M6 to M36 and offers excellent maneuverability for working with various metal components. Ideal for industrial applications requiring accuracy, speed, and ease of use.

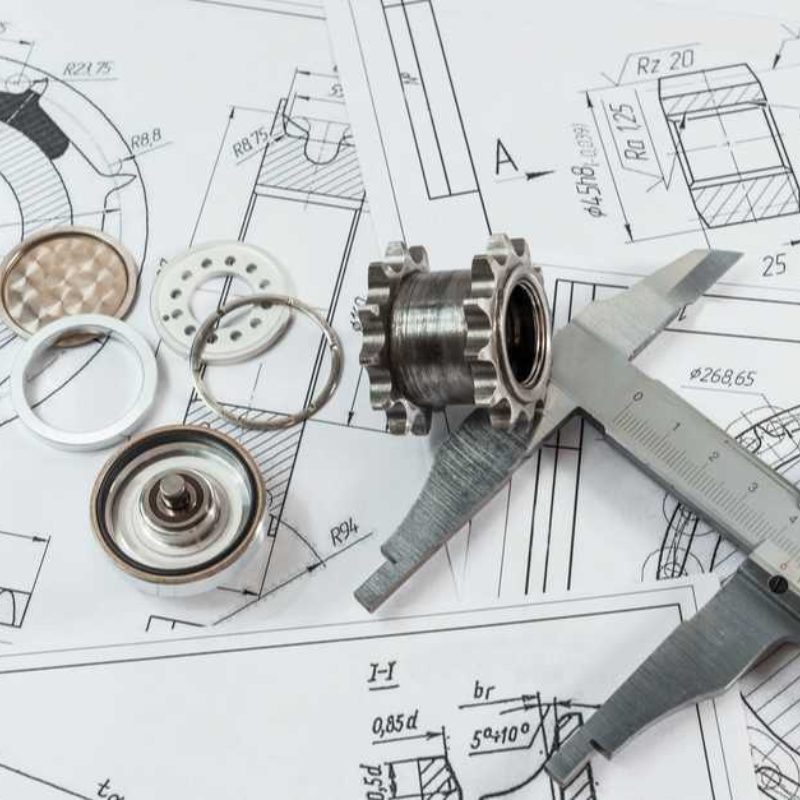

Product Features

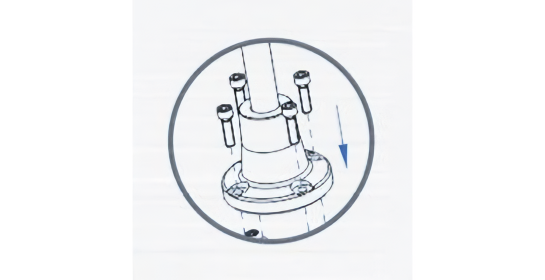

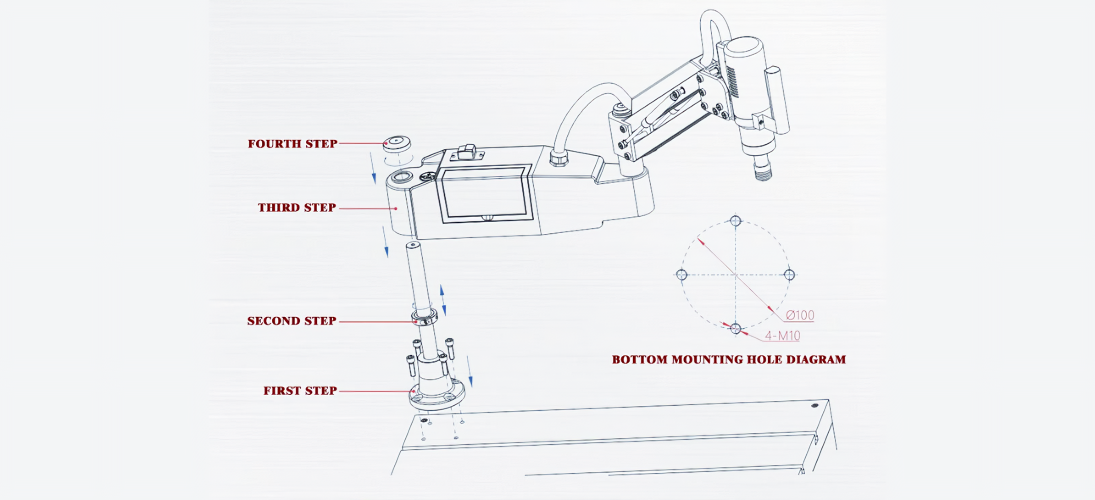

INSTALLTHEFOOTBASE

Align the footbasewith thescrew holes on theworkbench,and installfourscrews.

If the company workbench is not selected, you need to machine four mounting holes

on theworkbench by yourself.The processing dimensions are detailed in the following

"Foot base mounting hole position map".

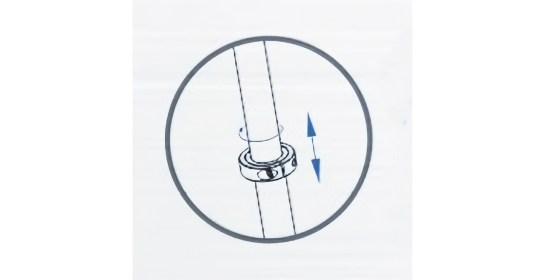

According to the actual situation, adjust the appropriate height,and tighten the screws

on the limit ring.

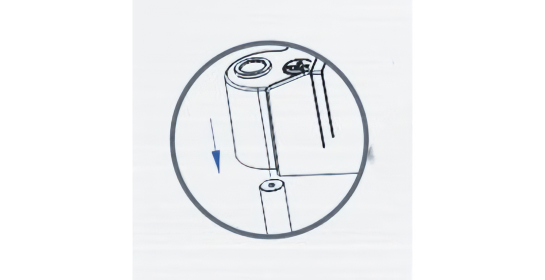

Put thecoppersleeve of thelower bracketof the tapping machineon the optical axis

of the foot base,and make the bottom copper sleeve close to the limit ring.

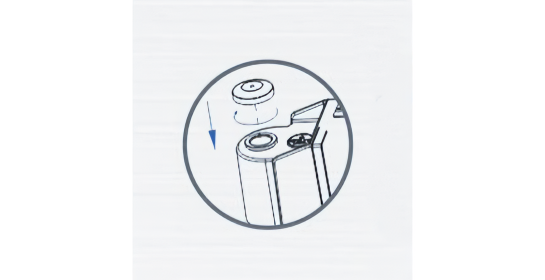

Align the optical axis cover with the screw hole on the top of the optical axis,insert it

correctly and tighten it.

Structure Diagram

Product parameters

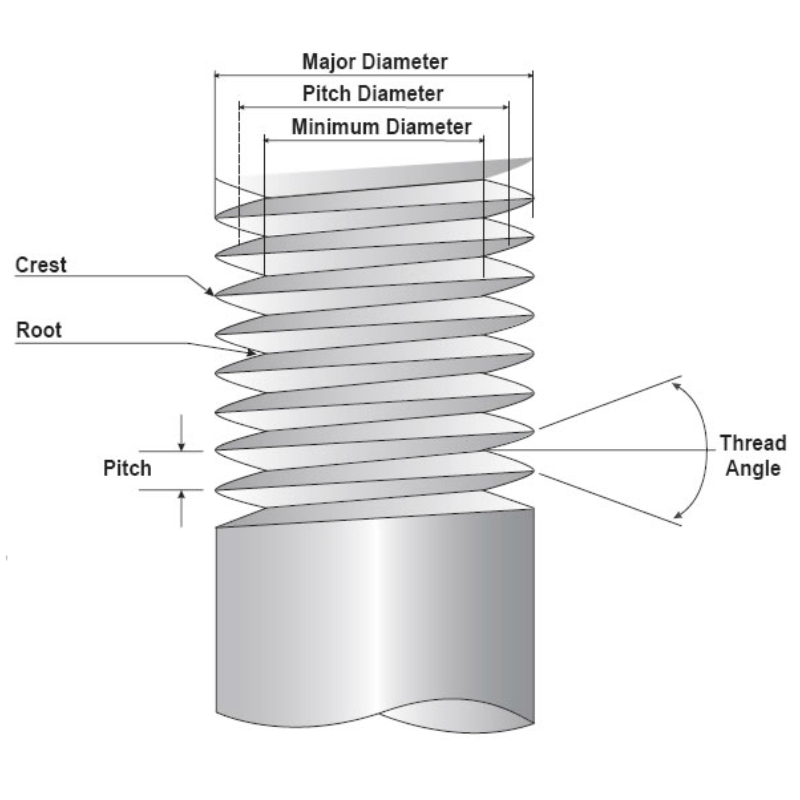

Parameter | Description |

Application Modes | Tapping, Drilling, Chamfering |

Thread Size Range | M6 – M36 (compatible with steel, stainless steel, aluminum, copper, etc.) |

Motor | High-performance 1.2 kW servo motor with overload protection |

Operation Modes | Manual, Semi-Automatic, Deep-Hole Mode; adjustable forward/reverse speed |

Working Radius | Horizontal reach: 1180–1300 mm / Vertical reach: ~400 mm / 360° full rotation |

Control System | Touchscreen HMI for controlling speed, direction, torque, and depth settings |

Collet Set | 14-piece safety collet set (compatible with ISO, JIS, DIN standard taps) |

Power Supply | 110V / 220V, 50/60Hz |

Machine Weight | Approx. 54 kg |

Compatible Materials | Metals: Carbon steel, stainless steel, aluminum, brass, cast iron / Engineering plastics |

Spindle Speed | Adjustable up to 125 RPM (depending on tap size and material) |

Optional Accessories | Magnetic base, mobile workbench, vertical extension arm, additional tap holders |

Warranty | 1-year warranty with after-sales support and user manual included |

Customer Information Required Before Custom Tapping

To ensure accurate and efficient tapping operations with the SFX‑M36R, please provide the following details:

|

|

1.Part Drawing or CAD File: | 2.Quantity Required: |

|

|

3.Material Information: | 4.Thread Specifications & Tolerances: |

|

|

5.Surface Treatment Conditions: | 6.Special Instructions: |

Strengths and Key Advantages of Our Factory

| Expertise and Professional Experience |

| Strict Quality Control |

| Advanced Technology and Modern Equipment |

| Comprehensive and Flexible Services |

| Reliability and Certified Standards |

| Continuous Development and Innovation |

Our Product

|

|

|

|

|

|

SFX-M36R Order Process (8 Steps)

| 1. Product Inquiry |

| 2. Requirement Analysis |

| 3. Official Quotation |

| 4. Order Confirmation |

| 5. Stock Preparation / Production |

| 6. Pre-Delivery Quality Check |

| 7. Shipping & Delivery |

| 8. After-Sales Support |

Comparison of processing technologies

Technology | Description | Advantages | Limitations | Suitable Applications |

SFX-M36R Electric Tapping Arm | Electric servo-driven arm for tapping M6–M36 threads | - Fast setup- Precise torque control- Portable and flexible- Low operator fatigue | - Requires power source- May not suit hard-to-reach internal spaces | Medium-to-large partsWorkshop tapping |

Manual Tapping | Hand-held tapping using tap wrench | - Low cost- Simple setup- Good for small quantity | - Slow- Prone to thread misalignment- Operator fatigue | PrototypingSmall repairs |

CNC Tapping (Rigid Tapping) | Integrated in CNC machining centers | - High precision- Fully automated- Great for large volumes | - High initial investment- Limited to CNC-equipped facilities | Mass productionHigh-precision parts |

Pneumatic Tapping Arm | Air-powered tapping tool with adjustable torque | - Fast operation- Lightweight- Cost-effective | - Requires compressed air- Less torque accuracy than electric | Assembly linesMedium production |

Vertical Tapping Machine | Bench-top or floor-mounted machines | - Stable and powerful- Repeatable results | - Fixed position- Less flexibility | High-volume same-part tapping |