Product Description

Integrated Drive and Control Grab Feedback Networking Applications

The ERG series electric rotary gripper is the industry explosive in 2021 and has made outstanding contributions to epidemic prevention and control.

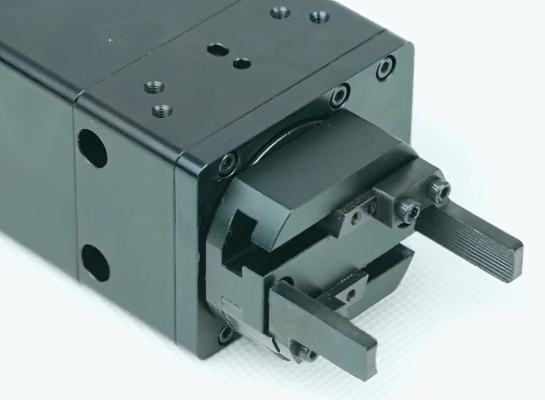

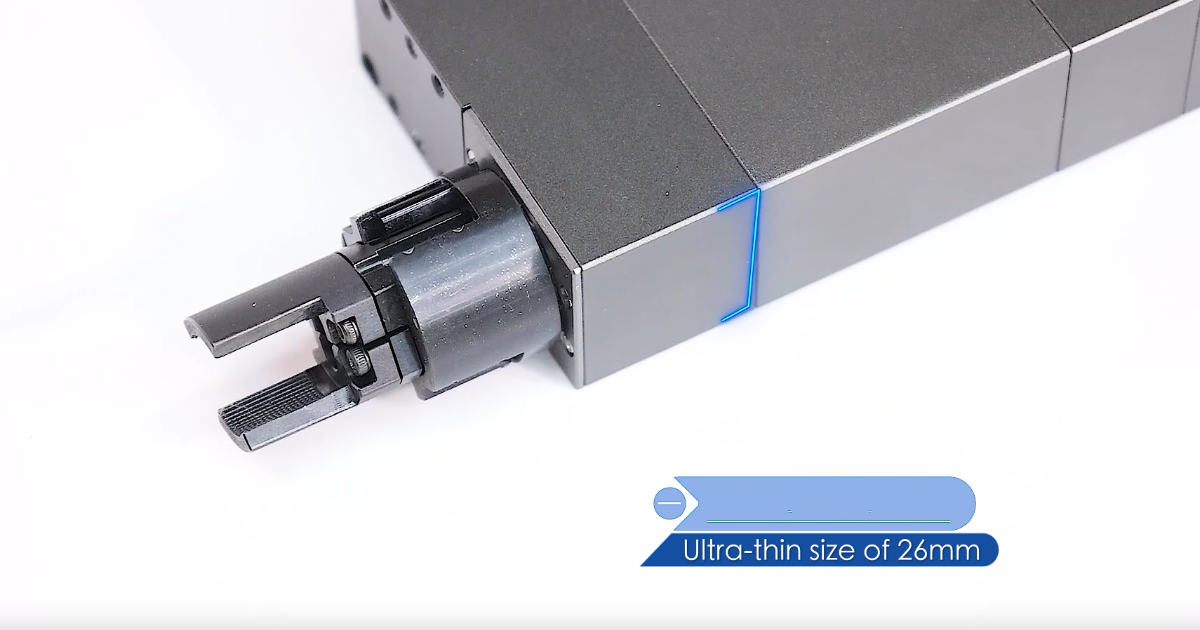

It adopts an integrated drive and control design with a compact structure and simple wiring, which is convenient for rapid deployment and system integration.

It supports unlimited rotation in both directions to meet the needs of complex workstations and multi-angle operations.

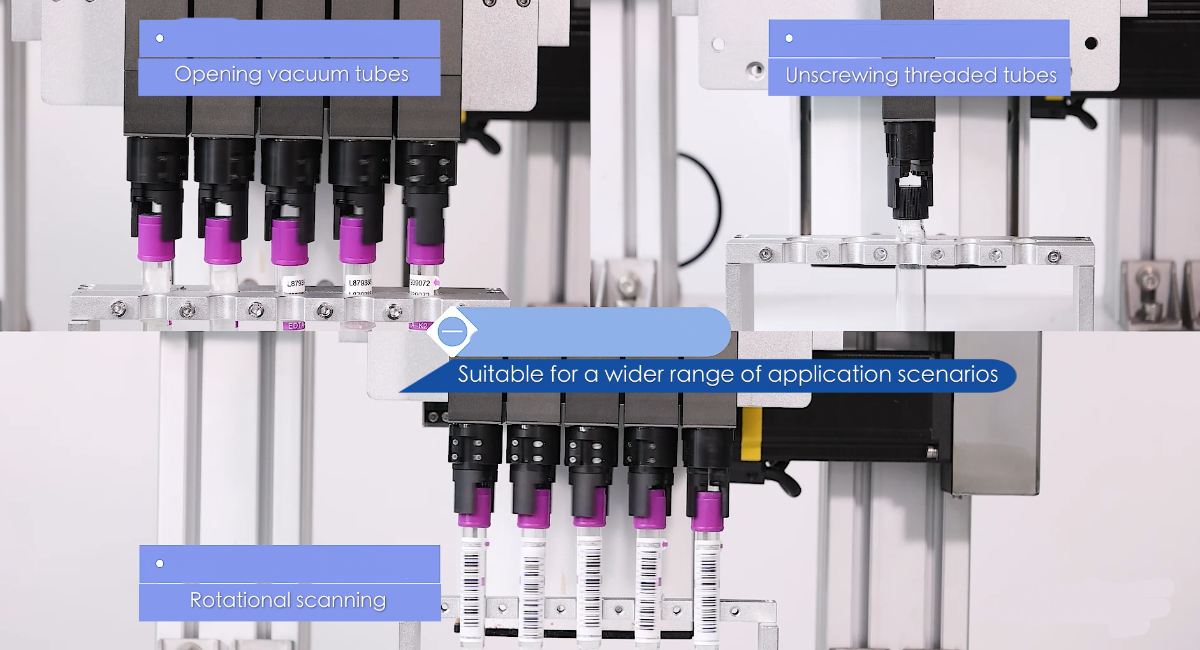

The gripping force, opening and closing position and rotation angle of the gripper can be flexibly set and accurately controlled to adapt to a variety of materials and application scenarios.

The built-in gripping feedback and drop detection functions significantly improve the reliability and safety of the system, especially for intelligent assembly, flexible gripping and high-beat operation scenarios.

It supports multi-device networking communication to help build intelligent collaborative robot work units.

Functional Features

Capable of rotating and opening OD 35mm caps for 20-in-1 test tubes

1. Integrated drive & control

2. Networking capability

3. Infinite rotation in

both directions

Grab feedback

Drop detection

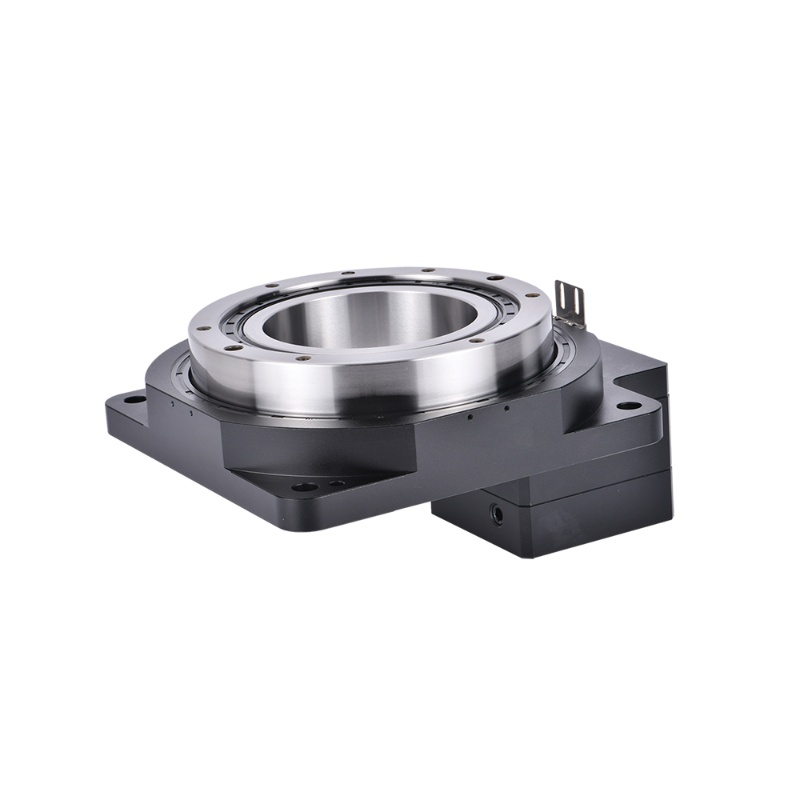

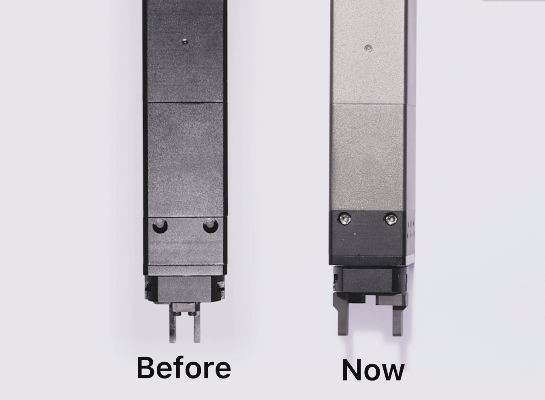

New upgraded version ERG32-150T High Torque Rotating Electric Gripper

Torque increased from 1NM to 1.5NM

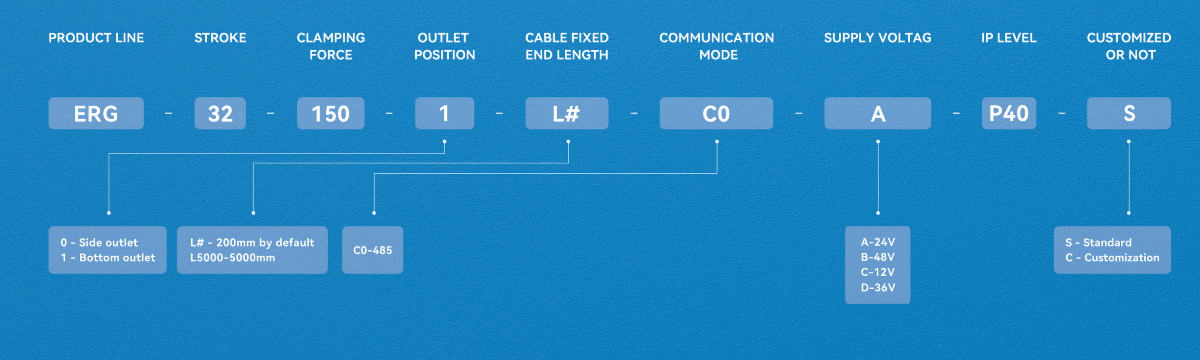

Selection Method

Product parameters

Model | ERG08-023 | ERG25-100L | ERG32-150 | ERG32-150T |

Adjustable stroke | 0-8mm | 0-25mm | 0-32mm | 0-32mm |

Single finger gripping force | 4-23N | 40-100N | 40-100N | 40-100N |

Opening/closing time | 0.15s | / | 0.5s | 0.5s |

Opening/closing speed | / | 80mm/s | / | / |

Peak torque | 0.3 N·m | 1 N·m | 1 N·m | 1.5 N·m |

Rated torque | 0.12 N.m | 0.2 N·m | 0.2 N·m | 0.3 N·m |

Rotation angle | Infinite rotation | Infinite rotation | Infinite rotation | Infinite rotation |

Maximum rotational speed | 1500°/s | 1500°/s | 1500°/s | 1000°/s |

Maximum allowable inertia | 100kg/mm² | 200kg/mm² | 200kg/mm² | 200kg/mm² |

Clamping repeatability accuracy | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

Rotation repetition accuracy | ±0.5° | ±0.5° | ±0.5° | ±0.5° |

*Maximum recommended load | 0.3Kg | 1.5Kg | 1.5Kg | 1.5Kg |

Drop detection | support | support | support | support |

Power outage maintenance | / | support | / | / |

Model | ERG08-023 | ERG25-100L | ERG32-150 | ERG32-150T |

Usage environment | 5-40° C, below 85% RH | 5-40° C, below 85% RH | 5-40° C, below 85% RH | 5-40° C, below 85% RH |

Running noise | <70dB | <60dB | <70dB | <70dB |

Body weight | 0.6Kg | 0.75Kg | 0.7Kg | 0.7Kg |

IP level | IP40 | IP40 | IP40 | IP40 |

Rated voltage | DC 24V±10% | DC 24V±10% | DC 24V±10% | DC 24V±10% |

Maximum current | 2A | 4A | 4A | 4A |

Rated current | 0.4A | 0.5A | 0.5A | 0.6A |

communication protocol | Modbus RTU(RS485) | Modbus RTU(RS 485)+I/O | Modbus RTU(RS 485) | Modbus RTU(RS 485) |

Compliant with international standards | CE、RoHS | CE、RoHS | CE、RoHS | CE、RoHS |

Vertical allowable static load Fz | 100N | 200N | 200N | 200N |

Permissible static moment of slider Mx | 1.5N.m | 2 N·m | 2 N·m | 2 N·m |

The allowable static moment of the slider My | 1.5N.m | 2 N·m | 2 N·m | 2 N·m |

The allowable static moment Mz of the slider | 1.5N.m | 2 N·m | 2 N·m | 2 N·m |

Note: This product does not include finger clips

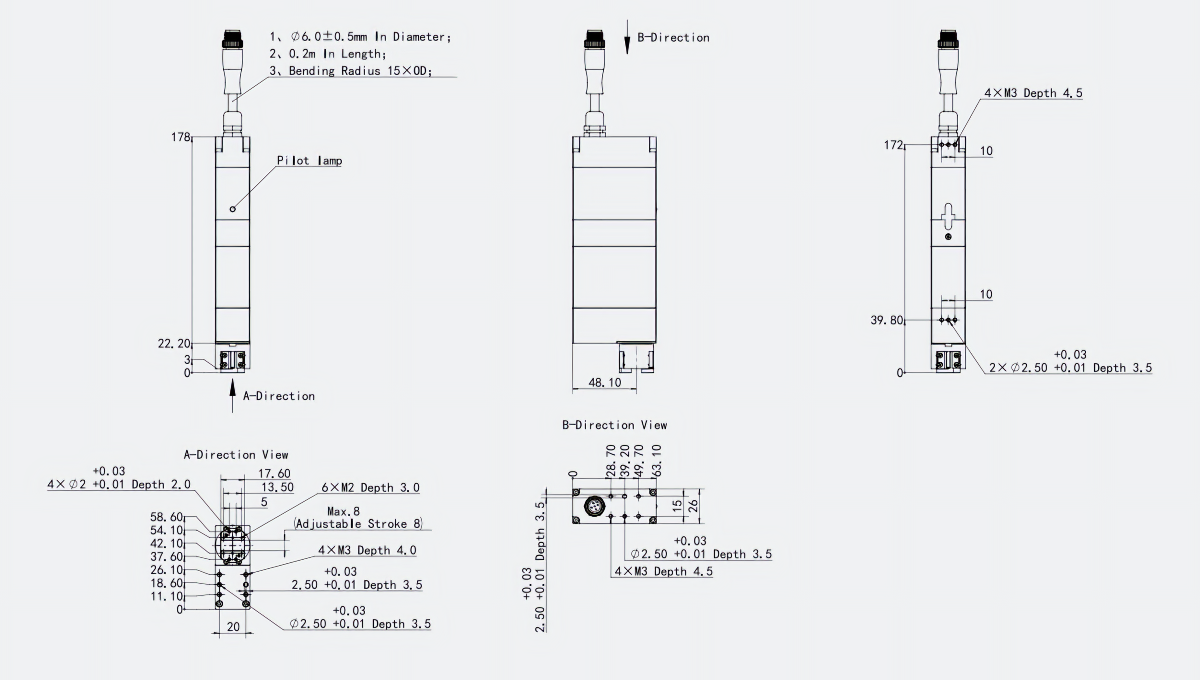

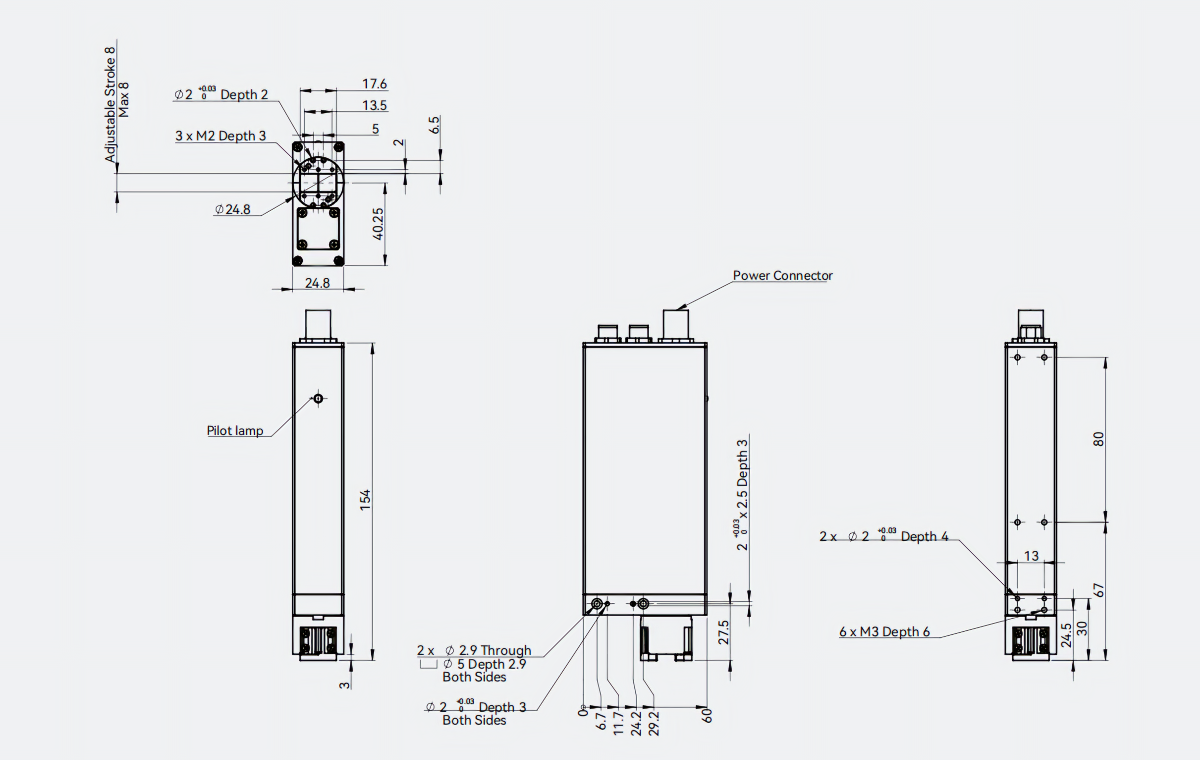

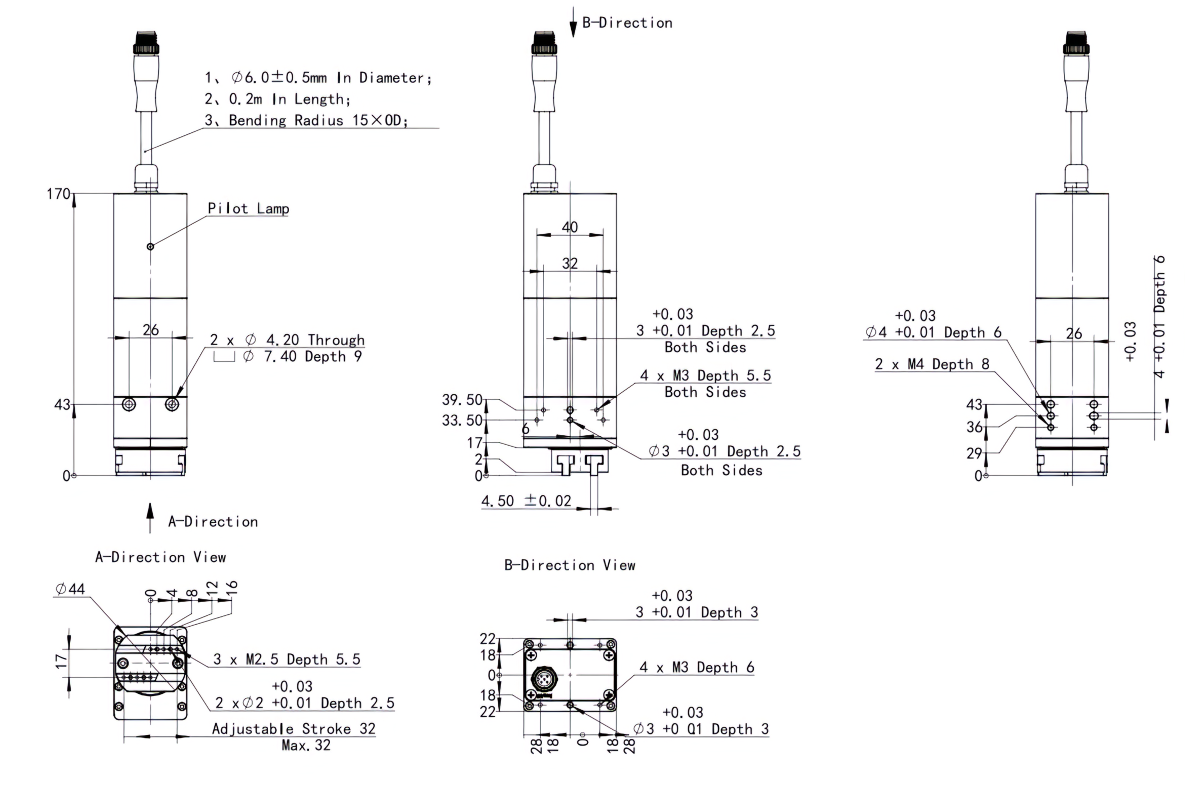

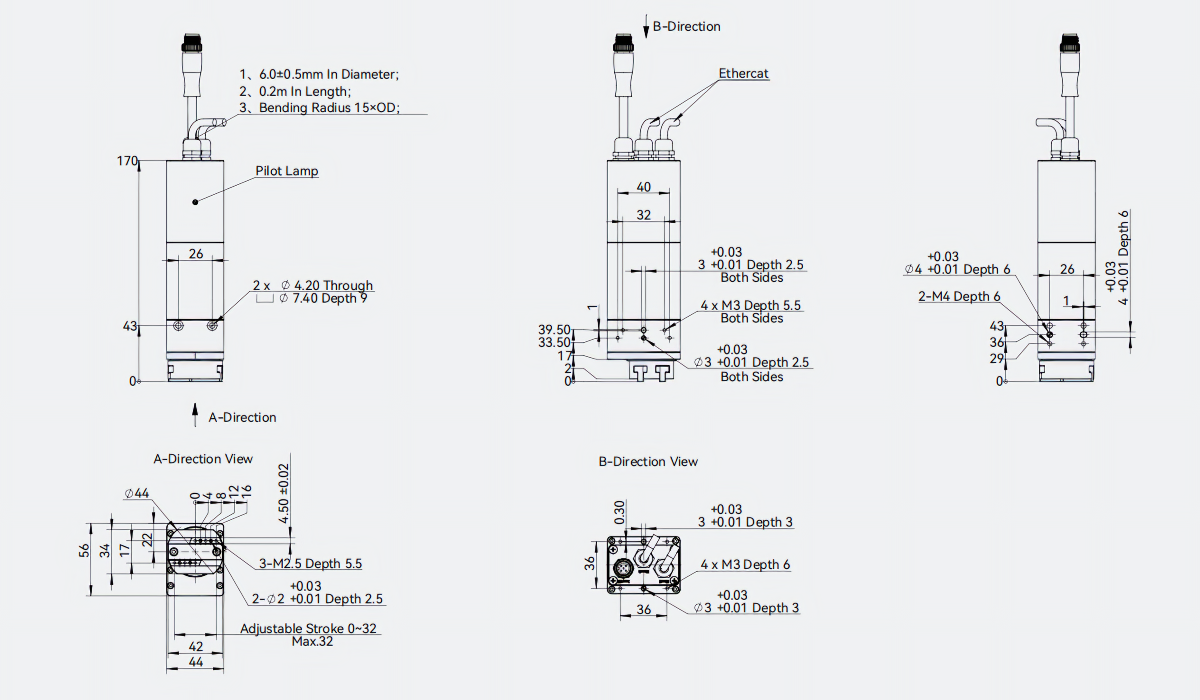

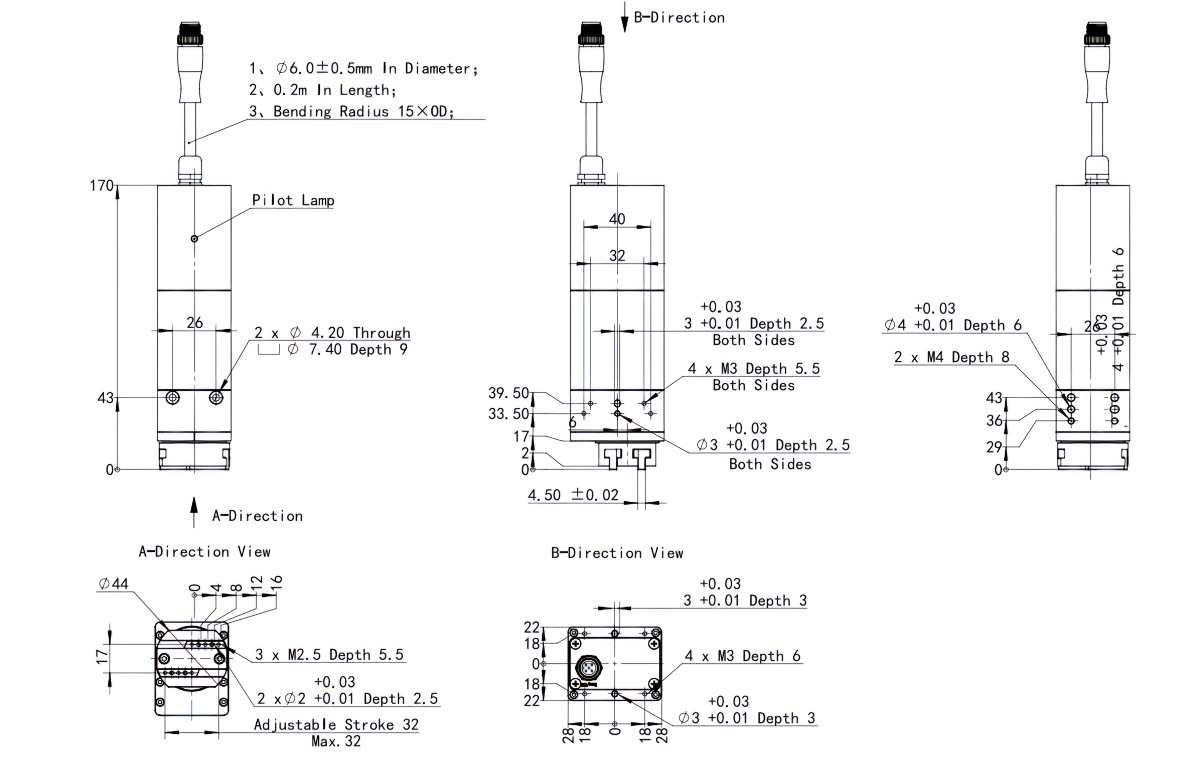

Dimension drawing

ERG08-023

Model: ERG08-023-1PU-L200-C0-N-A-P40-S00

ERG08-030

Model: ERG08-030-1PU-L200-C7-N-A-P40-S00

ERG32-150

Model: ERG32-150-1L#-C0A-P40-S

ERG32-150(E0)

Model: ERG32-150-1PU-L200-E0-N-A-P40-S00

ERG32-150T

Model: ERG32-150T-1L#-C0A-P40-S

Wiring Diagram

ERG32-150 for reference

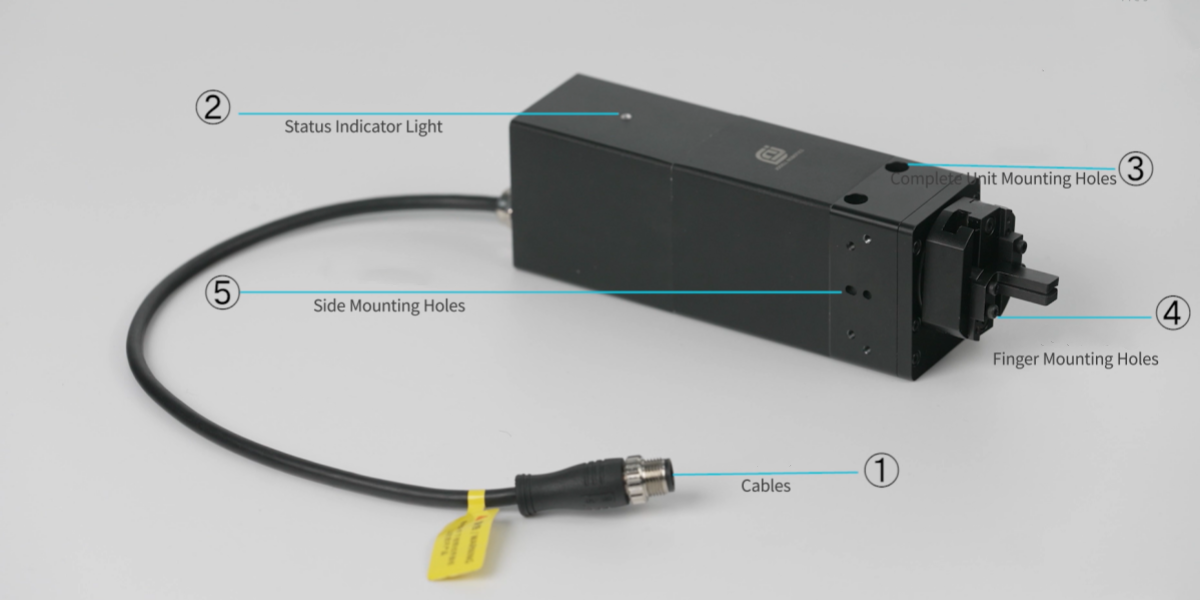

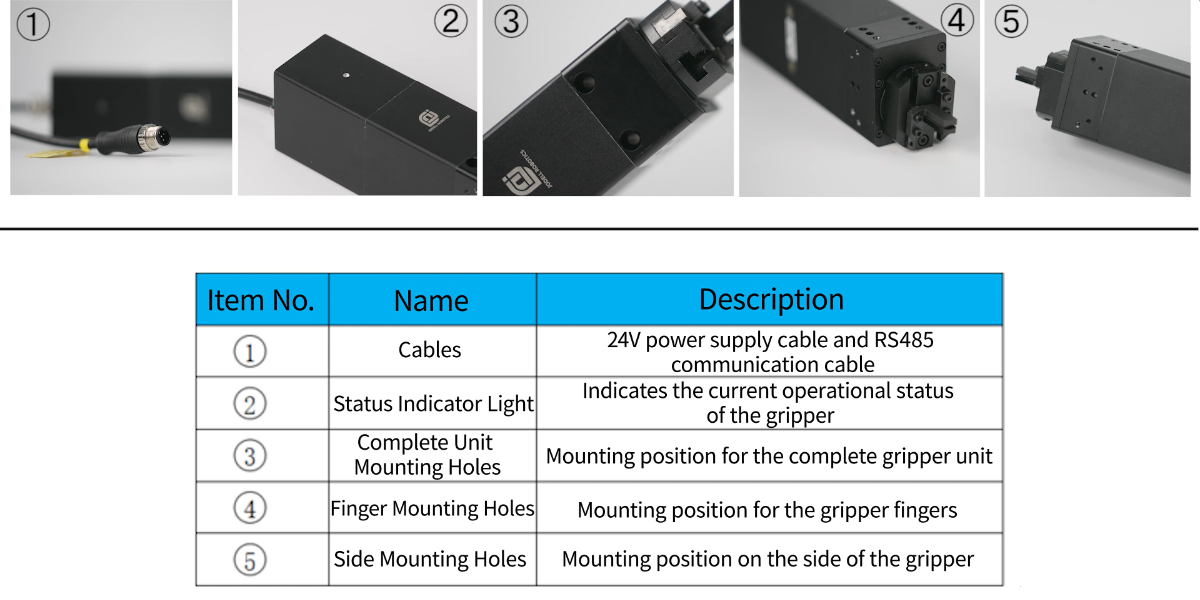

Product Detail

Application

It can be used for medical automation capping, scanning code detection and other scenarios for processing reagents, blood samples, nucleic acids and other samples, as well as 3C electronics, packaging automation, new energy industry positioning assembly, calibration and other scenarios.

Medical Automation Equipment Field

The ERG series electric servo gripper with micro-drive integrated rotary gripper has been applied in many automated inspection equipment. The compact integrated structure greatly simplifies the complicated integrated design of the clamping equipment in the past. Functions such as drop detection, gripping feedback, and power-off self-locking make the equipment more intelligent.

3C Component Assembly Testing Field

In the 3C field, which has extremely high appearance requirements for parts clamping, the ERG series electric grippers for irregular parts have functional characteristics such as high frequency and high precision, making parts clamping in the 3C field no longer difficult.

Packaging Automation Equipment Field

In the food, medicine and other packaging fields, the packaging needs to be intact and used frequently, which requires the packaging to be clamped frequently and stably. The ERG series modular electric grippers perfectly meet the clamping requirements of the packaging industry and provide an excellent industry solution.

Service

1. Warranty commitment

-Provide 12 months warranty (from the date of leaving the factory or delivery)

-During the warranty period, non-human damage can be replaced/repaired free of charge

2. Remote technical support

-Provide English technical support (email, video, remote debugging)

-Response time can be promised within 24 hours

3. Complete technical information

-Provide complete product manuals, installation instructions, wiring diagrams, debugging guides

-Some products can be attached with 3D models (STEP), electrical interface protocols, communication sample codes