Product Description

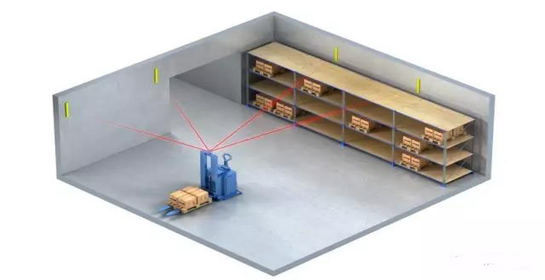

IntelliStack™ 1600SL is a next-generation autonomous forklift robot designed for intelligent material handling in dynamic industrial environments. Featuring laser SLAM navigation with ±10mm precision and no need for reflectors, it ensures rapid deployment and superior handling of standard, Euro, and custom pallets.

Equipped with a comprehensive sensor suite, including 360° laser obstacle detection, 3D cameras, and safety bumpers, IntelliStack™ delivers reliable, high-speed, and safe stacking and transport of goods up to 1.6 tons at 3 meters. With integrated system communication, it connects seamlessly to dispatch systems for real-time dynamic scheduling.

Application Scenarios

| Industry | Use Cases |

| Warehousing & Logistics | Autonomous stacking, transport of Euro pallets, zone-based goods handling |

| Manufacturing | Material delivery between production lines and storage zones |

| Retail Distribution | Goods transfer from inbound to shelf area, order picking support |

| Cold Chain / Pharma | Precise movement in controlled temperature environments |

| Automotive & Parts | Transporting components and crates between workstations and buffer storage |

Advantage

| Feature | Details |

| SLAM Navigation (±10mm) | Reflector-free, laser-based with fast and flexible deployment |

| 1.6T Load @ 3m Lift | Full capacity maintained even at maximum lifting height |

| High Speed Movement | Runs at up to 2 m/s under both full and no load |

| Modular Industrial Design | Easy to disassemble, maintain, and upgrade (sensor brackets, wiring, panel) |

| Smart Pallet Recognition | Supports international, Euro, and custom-size pallets |

| 360° Safety Suite | Laser scanners, 3D vision, bumper sensors, safety edge, E-stop button |

| System Integration Ready | Compatible with dispatch and fleet management systems |

Product Features

Precision Laser SLAM Navigation with ±10mm Accuracy

No need for reflectors — enables quick, flexible deployment and reliable autonomous navigation even in complex warehouse layouts.

Full Load Capacity at Maximum Lift Height

Handles up to 1.6 tons at 3 meters lift height without any loss in performance or stability, perfect for efficient stacking and transport.Product parameters

| Parameter | Specification |

| Navigation Method | Laser SLAM (No reflector), ±10mm accuracy |

| Load Capacity | 1600 kg (1.6T) |

| Lifting Height | Up to 3 meters (full load capacity maintained) |

| Max Running Speed | 2.0 m/s (both full-load and no-load) |

| Braking Distance | ≤30 cm @ 1 m/s; ≤50 cm @ 1.5 m/s |

| Safety Features | 360° Lidar, 3D cameras, bumper strip, E-stop, etc. |

| Lidar Configuration | 1×H1 (front), 2×C2 (sides) |

| Obstacle Detection | Full coverage with real-time object avoidance |

| Fork Accuracy | High-precision forking of various pallet types |

| Hardware Fault Detection | Built-in monitoring and safety alert system |

| Communication | Dispatch system connectivity, real-time data sync |

Customer Case

Item Searching

Sorting by Code

Multi-Pallet Towing

FAQ

1. Does the robot require reflectors for navigation?

No. It uses laser SLAM technology and does not require reflectors, making setup and layout changes much easier.

2. Can it maintain full load capacity at full height?

Yes, it can lift 1.6 tons up to 3 meters without compromising stability or performance.

3. What pallet types does it support?

It supports standard, Euro, and non-standard/custom pallets, with smart identification and precise forking.

4. Is it compatible with fleet management or WMS systems?

Yes, it integrates with dispatch and warehouse systems via open protocols for smart scheduling.

5. What safety systems are built in?

It features 360° laser obstacle detection, 3D cameras, safety bumpers, E-stop buttons, and braking sensors for full-area safety.

Pack

Protective Packaging: Each unit is securely wrapped in anti-static foam padding and heavy-duty shrink wrap to protect against dust, moisture, and mechanical shocks during transit.

Custom Crating: The forklift is mounted on a robust wooden crate with reinforced steel brackets to minimize vibration and movement.

Component Protection: Sensitive components like sensors, LIDAR, and control panels are separately cushioned and secured inside the crate.

Easy Handling: The crate is equipped with forklift slots and lifting points for safe loading and unloading.

Documentation: Each package includes a detailed packing list, user manual, and inspection checklist.

Transport

Domestic Shipping: Delivered via trusted logistics partners specializing in industrial machinery transport with door-to-door service.

International Shipping: Fully compliant with international shipping regulations, including export packaging standards (ISPM 15 wood packaging).

Shipping Modes: Available by sea freight, air freight, or express courier depending on urgency and destination.

Tracking & Support: Shipment tracking and real-time status updates are provided. Our logistics team supports customs clearance and documentation handling.

Installation Support:

On-site Delivery: Optionally, we provide installation and commissioning support at your site to ensure smooth deployment.

Training: Operator and maintenance training can be arranged post-delivery for your team.