Product Description

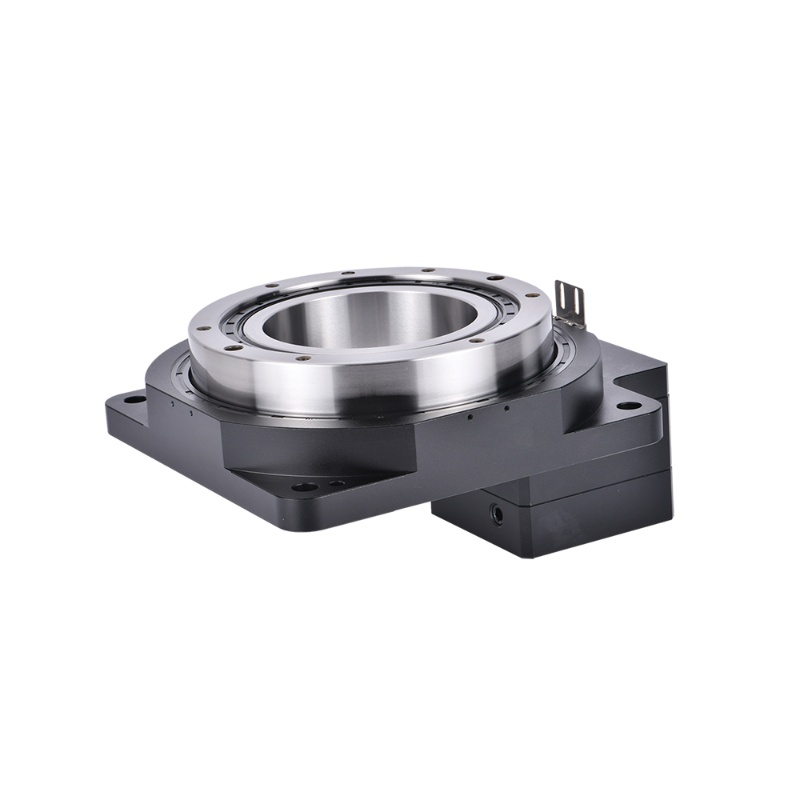

HOLLOW ROTATING PLATFORM

5 arcsec repeated positioning accuracy

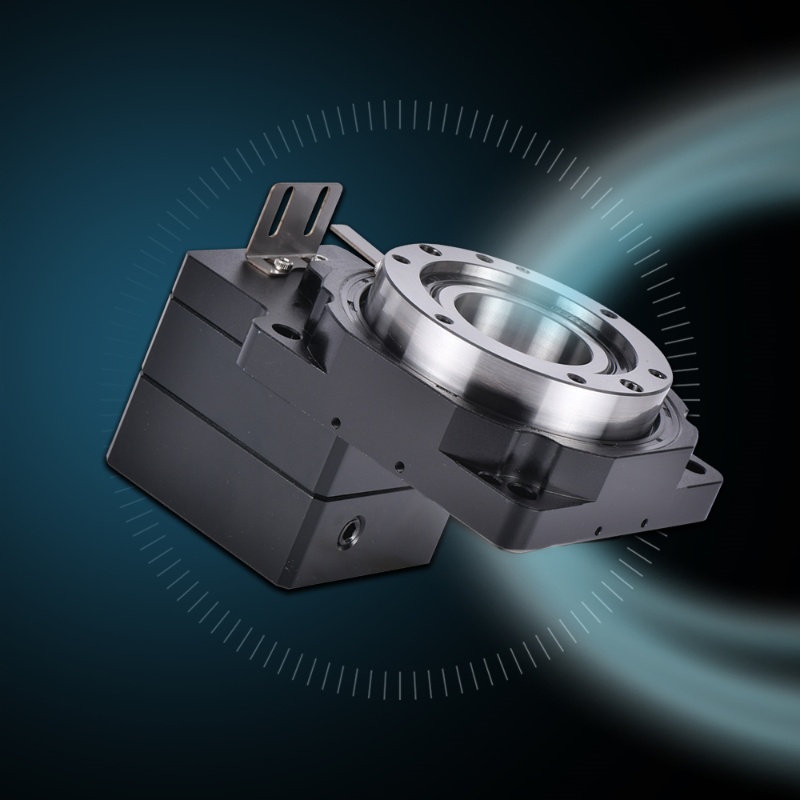

360° arbitrary installation

Can be matched with step motor or servo motor

The servo rotating platform produced by our company is characterized by super-heavy load, high rotation accuracy and low side clearance. Its product categories include coaxial type, paraxial type and right Angle type, which are mainly suitable for robot arm, CNC turntable, alignment mechanism, automation and measurement and test in the field requiring high precision.

Features

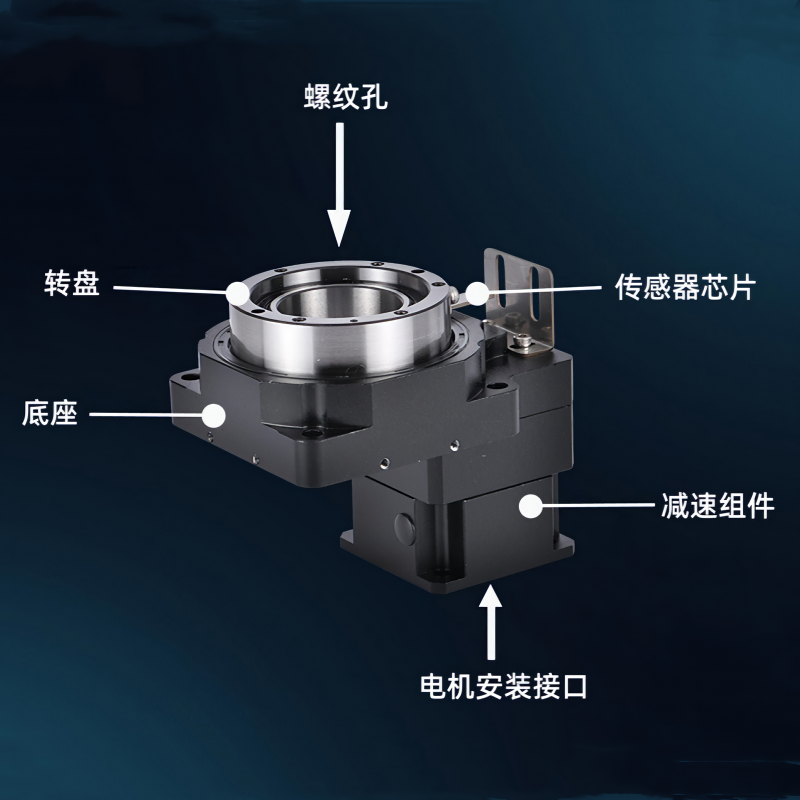

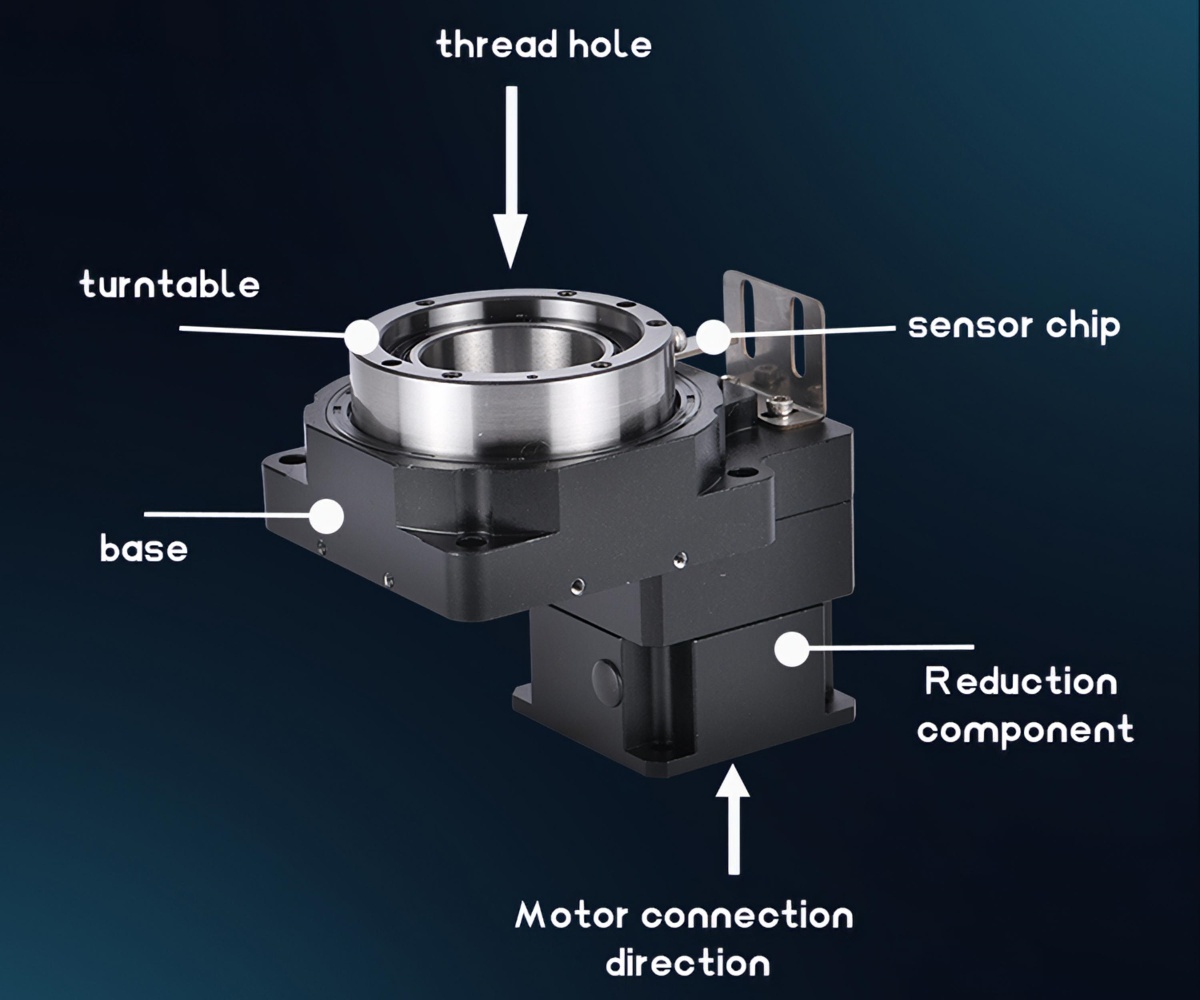

This product includes the following important components: Thread hole, Sensor chip, Turntable, Base, Reduction component, Motor connection direction. The turntable of the hollow rotating platform is hollow structure, and the motor is connected on the side to facilitate the installation of the gas pipe and wire in the fixture.

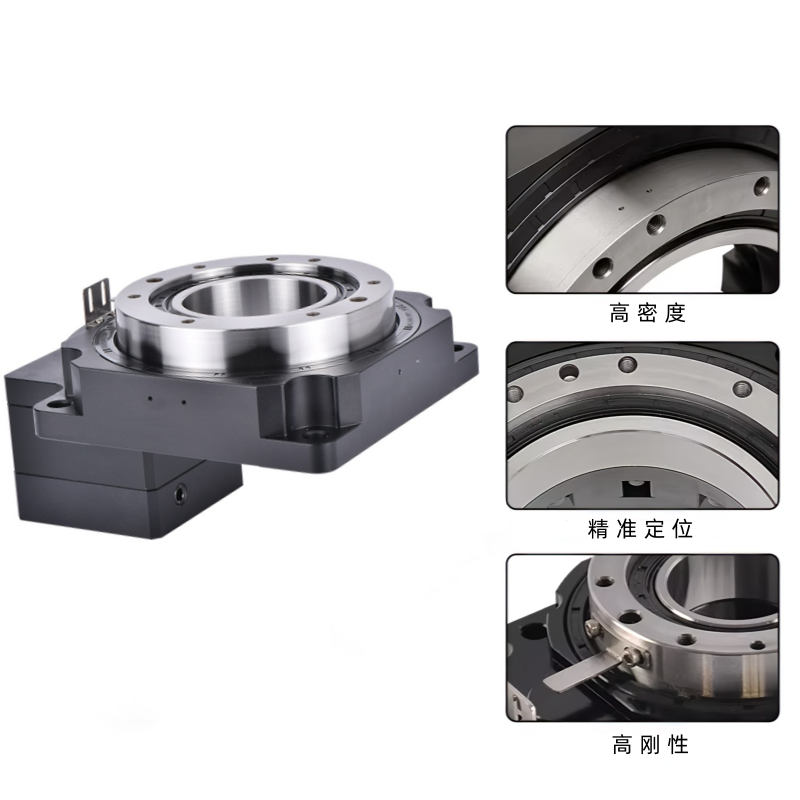

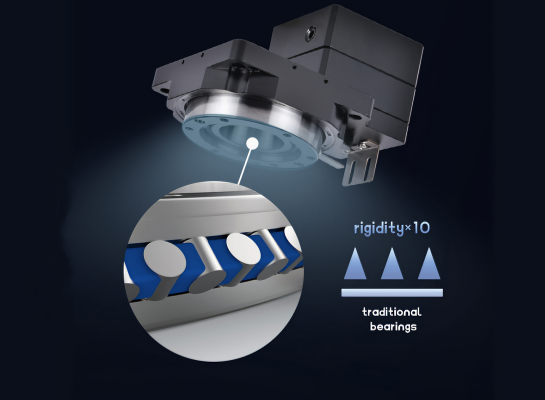

The turntable of this series servo

rotating platform is supported by a set of precision cross roller bearings

High Rigidity

High Rotation Accuracy

The repeat positioning accuracy can below 10 arcsec

High Repeat Positioning Accuracy

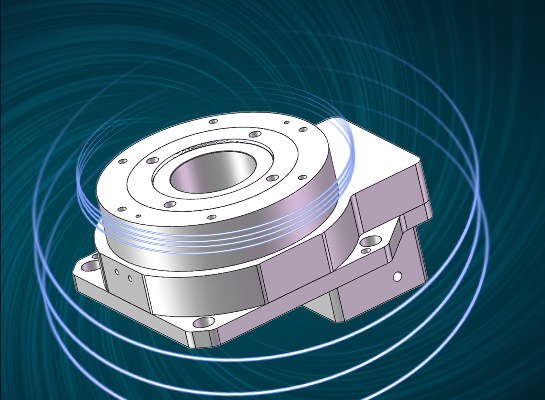

This series of rotating platform can

be combined with planetary deceleration

to increase the output torque.

High Torque Low Backlash

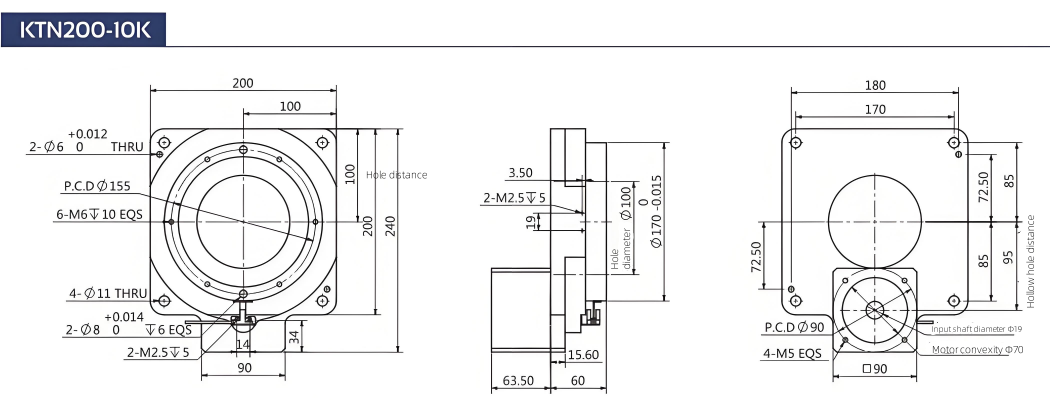

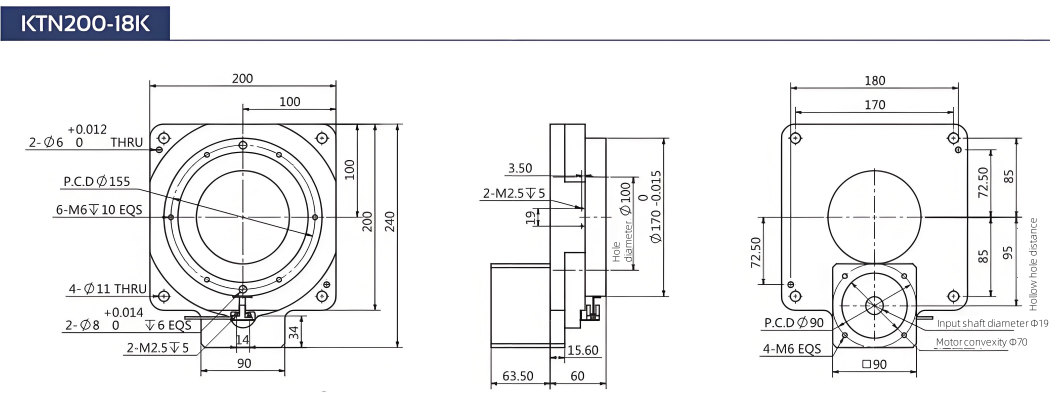

Dimensional drawing

Product parameters

Model | TN60-5K | TN60-10K | TN85-5K | TN85-10K | TN85-18K | TN110-5K | TN110-10K |

Rotary platform bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing |

Reduction ratio | 1:05 | 1:10 | 1:05 | 1:10 | 1:18 | 1:05 | 1:10 |

Allowable input torque(Nm) | ≤5.2 | ≤5 | ≤40 | ≤35 | ≤20 | ≤47 | ≤35 |

Allowable platform speed(rpm) | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

Positional accuracy(arcsec) | ±30 | ±30 | ±30 | ±30 | ±30 | ±30 | ±30 |

Repeated positioning accuracy(arcsec) | ±15 | ±15 | ±15 | ±15 | ±15 | ±15 | ±15 |

Allowable axial load(N) | 200 | 200 | 400 | 400 | 400 | 800 | 800 |

Rotating platform flatness(mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

Rotating platform concentricity(mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

Protection level | IP40 | IP40 | IP40 | IP40 | IP40 | IP40 | IP40 |

Precision life(hrs) | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 |

Weight(kg) | 1.2 | 1.2 | 1.8 | 1.8 | 1.8 | 2.6 | 2.6 |

Model | TN130-10K | TN130-18K | TN170-10K | TN200-10K | TN200-18K | TN280-10K | TN280-18K |

Rotary platform bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing |

Reduction ratio | 1:10 | 1:18 | 1:10 | 1:10 | 1:18 | 1:10 | 1:10 |

Allowable input torque(Nm) | ≤55 | ≤55 | ≤72 | ≤90 | ≤90 | ≤135 | ≤135 |

Allowable platform speed(rpm) | 100 | 100 | 100 | 100 | 100 | 60 | 60 |

Positional accuracy(arcsec) | ±30 | ±30 | ±30 | ±30 | ±30 | ±30 | ±30 |

Repeated positioning accuracy(arcsec) | ±15 | ±15 | ±15 | ±15 | ±15 | ±15 | ±15 |

Allowable axial load(N) | 1000 | 1000 | 1000 | 2000 | 2000 | 4000 | 4000 |

Rotating platform flatness(mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

Rotating platform concentricity(mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

Protection level | IP40 | IP40 | IP40 | IP40 | IP40 | IP40 | IP40 |

Precision life(hrs) | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 |

Weight(kg) | 4 | 4 | 10 | 10 | 10 | 19 | 19 |

Adaptive motor | 57 stepper motor | 57 stepper motor | 86stepper motor | 86stepper motor | 86stepper motor | 130frame servo motor | 130frame servo motor |

Application

Hollow rotary platforms are widely used in collaborative robots, automated assembly lines, visual inspection systems, semiconductor equipment and other fields. They are suitable for scenarios that require high-precision rotation positioning and hollow routing.

Product Delivery

Our Advantages

Direct connection can improve reliability and reduce costs. The workbench and robot arm that need to be installed can be directly installed on the rotating platform. Compared with the use of mechanical parts such as pulleys, the time and cost of mechanical design, parts allocation, belt state adjustment and other links can be reduced.

Motor configuration

You can freely choose stepper motors or servo motors of various brands, except for the KTN series dedicated stepper motors.

High-precision positioning without backlash

No backlash, positioning accuracy ≤15sec, and repeated positioning accuracy can reach ±5sec.

Large-diameter hollow structure

Wiring and piping are more convenient and simple, and this feature is particularly prominent in wiring and piping environments with complex wiring.