Product Description

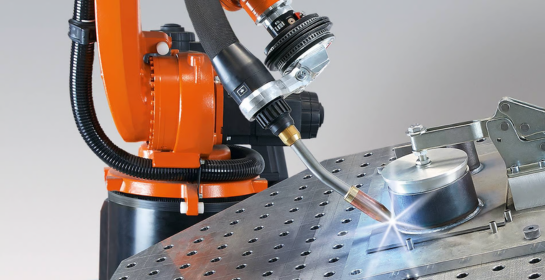

The 6-axis intelligent welding robot is engineered for precision and versatility across a wide range of welding applications. With a 6 kg payload and an impressive 2005 mm reach, this robotic system is capable of handling both small-scale intricate welds and large-scale structural assemblies with exceptional efficiency.

Equipped with advanced motion control algorithms and intelligent path planning, the robot ensures consistently high welding accuracy and repeatability, making it ideal for automotive, heavy machinery, metal fabrication, and general manufacturing industries. Its compact design, combined with long reach and agile movement, enables it to access complex weld seams and confined workspaces.

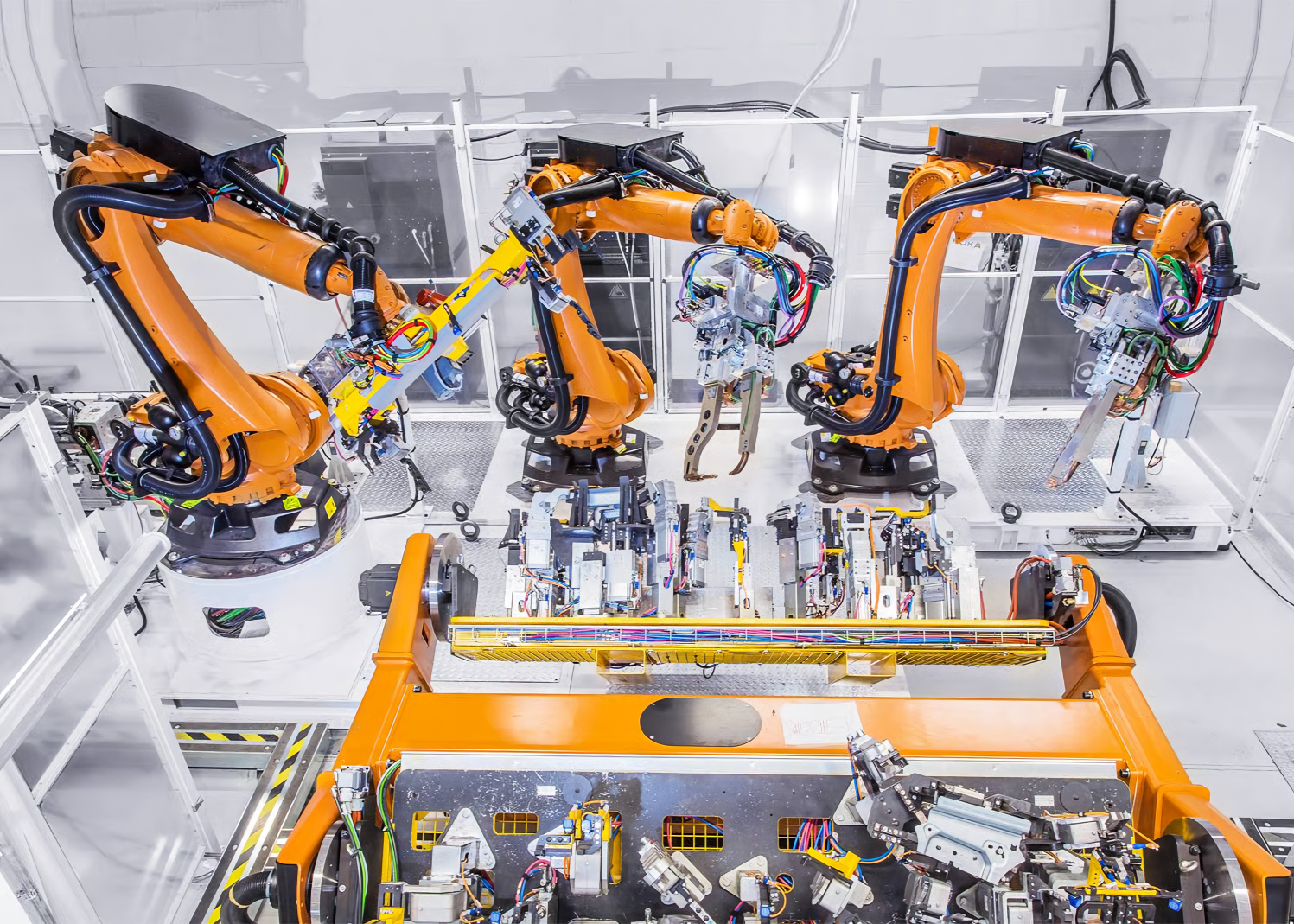

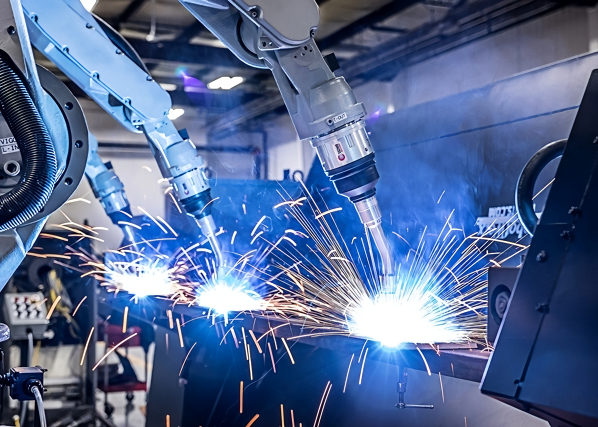

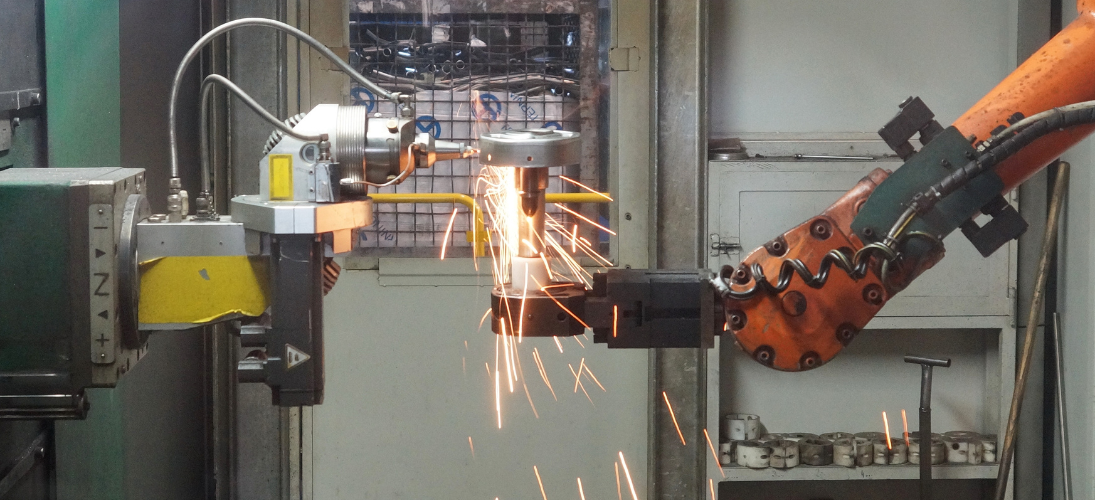

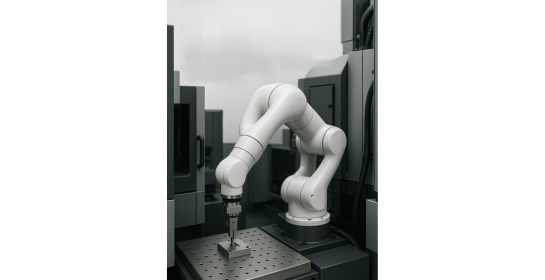

Our Product

|

|

|

|

Product Features

High-Precision Welding

Delivers exceptional accuracy with a repeatability of ±0.05 mm, making it ideal for fine welding tasks in automotive, structural, and electronic applications.

Extended Reach for Complex Jobs

With a horizontal and vertical reach of 2005 mm, the robot covers a wide working envelope without the need for a linear track system.

Compact & Interference-Free Design

Features a contoured upper arm that provides easy access in tight spaces. Its interference-minimizing structure supports close-proximity robot installations.

Fast Motion & High Dynamics

Engineered for high-speed axis movement and rapid acceleration, allowing for faster cycle times and improved productivity on the shop floor.

Product parameters

Specification | Details |

Axes | 6 Controlled Axes |

Maximum Payload | 6 kg |

Horizontal Reach | 2005 mm |

Vertical Reach | 2005 mm |

Repeatability | ±0.05 mm |

Robot Weight | 160 kg |

Internal Wiring | 24 conductors + ground wire |

Internal Air Line | 1/0 user air channel |

Power Requirements | 2.5 kW / 3.125 kVA |

Connections | 3/8" fittings |

Controller | i8 Robot Controller (Teach Pendant + G-code) |

Interface | USB, RS232, 48 inputs / 32 outputs |

Display | 8” Real Color LCD |

CPU Architecture | ARM 32-bit + DSP + FPGA |

Storage | 256MB (Expandable to 2GB) |

Motion Control | Point-to-Point, Torque, Speed, Position Modes |

Position Accuracy | ±0.01% |

Servo Motor Power Range | 100W–11kW |

Supported Voltage Input | ~220V ±20% or ~380V ±20% |

Pulse Input Frequency | < 500 kHz |

Analog Input | 0–10V or ±10V |

Overload Protection | Current, Voltage, Heat, Short Circuit, Encoder |

Noise Level | Low (Optimized Space Vector Algorithm) |

Optional Functions | CNC, PLC Control, Dynamic Braking |

Service

Order Process Flowchart

| Design & Specification |

| Quotation & Project Evaluation |

| Processing & Manufacturing |

| Quality Inspection |

| Delivery |