Product Description

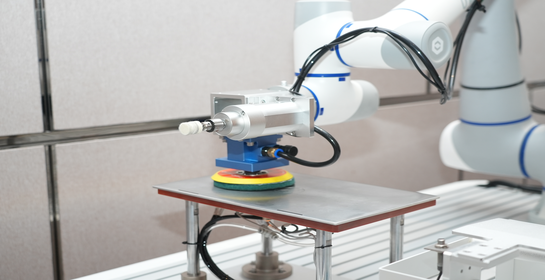

ProPolish™ Collaborative Robotic Polishing System is a cutting-edge, automated surface finishing solution designed to elevate the productivity, precision, and safety of polishing and sanding operations across various industries. Engineered with advanced motion control, smart tool adaptability, and an intuitive interface, ProPolish™ seamlessly integrates into existing workflows. It transforms labor-intensive manual tasks into efficient, repeatable processes — all while ensuring superior surface finishes and minimizing worker exposure to dust, noise, and repetitive strain.

With plug-and-play functionality, advanced polishing toolkits, and real-time adaptive feedback, ProPolish™ is your ideal partner for achieving consistent, high-quality surface results on metal, plastic, wood, and composite materials.

Application & Material Compatibility

| Material Type | Application | Tool Used | Finish Quality |

| Aluminum | Deburring, mirror polishing | Random Orbital Sander + Polishing Pad | High Gloss |

| Stainless Steel | Scratch removal, fine polishing | Auto Deburring Tool + Polishing Paste | Industrial-grade |

| Wood | Surface smoothing & varnish prep | Random Orbital Sander | Fine Finish |

| Plastic/Composite | Buffing, sanding & contour shaping | Soft Polisher Pad + Light Abrasive | Uniform & Smooth |

Product Features

Auto Tool & Grit Changer System

ProPolish™ comes equipped with an automated tool and abrasive switching system, enabling the cobot to seamlessly shift between sanding discs, polishing pads, or deburring tools based on the material and finishing stage — all without human intervention. This ensures uninterrupted workflow, zero downtime, and multi-stage surface finishing in a single run.

Key Benefits:

Reduces tool changeover time by up to 80%

Enhances multi-material versatility

Improves overall process efficiency

Intelligent Surface Mapping and Force Control

With integrated force-torque sensors and real-time surface mapping, ProPolish™ adapts dynamically to curved or uneven surfaces, maintaining constant pressure and consistent finish across the entire part. Ideal for delicate materials or complex geometries.

Key Benefits:

Prevents over-polishing or under-processing

Maintains surface integrity and finish quality

Ideal for aerospace, medical, or automotive parts

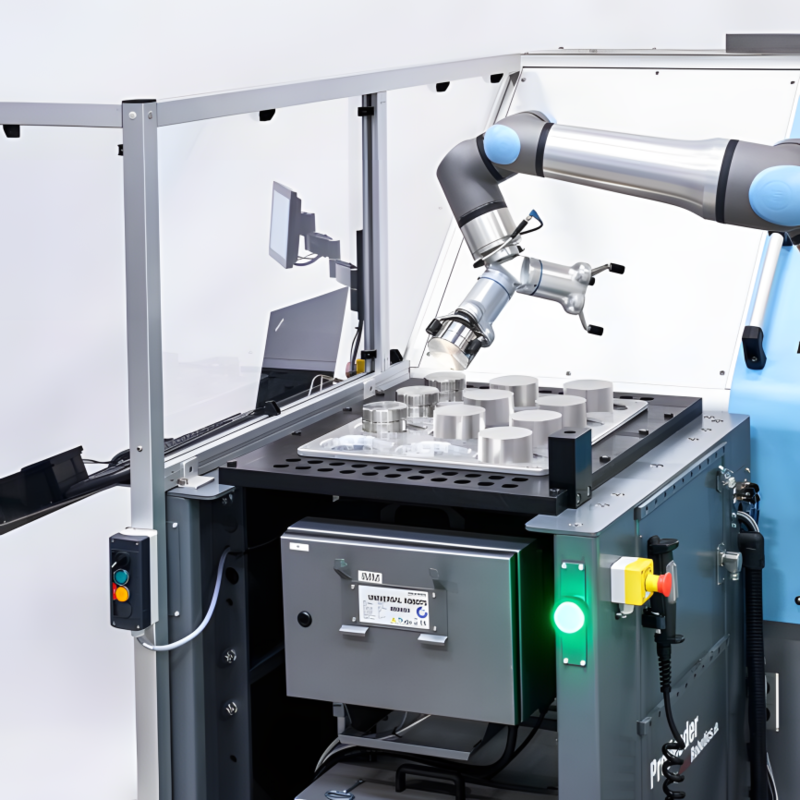

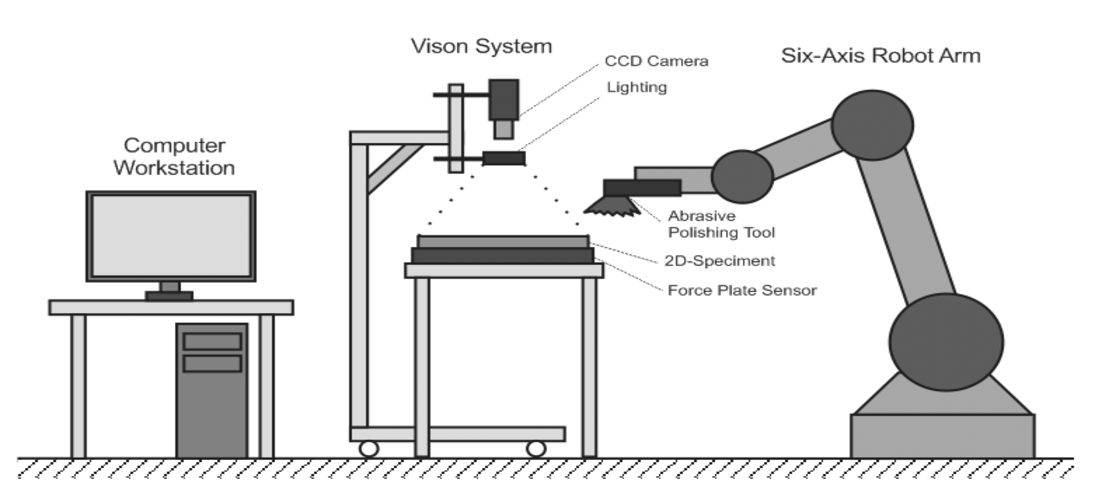

Structure Diagram

Product parameters

| Parameter | Specification |

| Cobot Arm Reach | 900mm – 1300mm (model dependent) |

| Payload Capacity | Up to 10kg |

| Repeatability | ±0.03 mm |

| Tool Mount Interface | ISO 9409-1-50 |

| Compatible Tools | Sanders, polishers, deburring tools |

| Programming Interface | Touchscreen with drag-and-drop UI |

| Power Supply | 100–240V AC |

| Safety Compliance | ISO/TS 15066 (Collaborative Safety) |

| Operating Environment | 0–45°C, non-condensing |

| Connectivity | Ethernet, USB, Modbus, I/O |

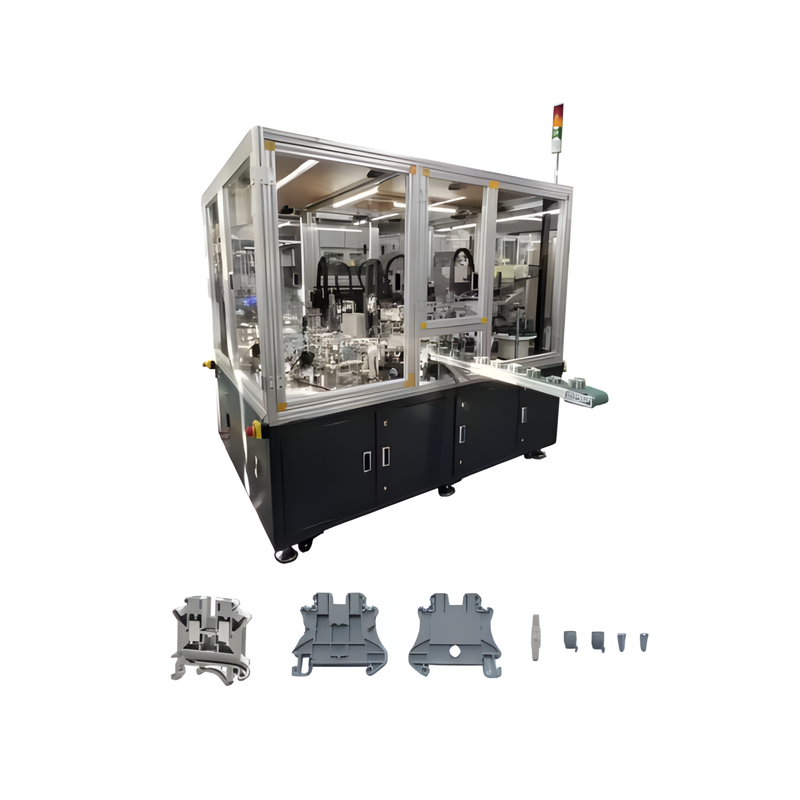

Customer Case

Aerospace Component Finishing

Wood Furniture Manufacturing

Medical Device Surface Buffing

FAQ

| Frequently Asked Questions |

| Q1: What industries benefit most from ProPolish™? A: Aerospace, automotive, woodworking, medical device manufacturing, and metal fabrication industries gain the most due to ProPolish™’s precision and safety. |

| Q2: Is programming the cobot difficult? A: Not at all. It features a graphical drag-and-drop interface, and most users can set up basic tasks within an hour, no coding required. |

| Q3: Can ProPolish™ work alongside humans safely? A: Yes, it is fully collaborative, featuring force-limited joints and safety-rated monitored stops to ensure safe operation next to people. |

| Q4: How long does a tool change take? A: With the auto tool changer, it takes less than 15 seconds for a complete tool and grit switch. |

| Q5: What surfaces or materials can it polish? A: It can polish and sand metal, plastic, wood, and composites using a wide range of toolkits. |