Product Description

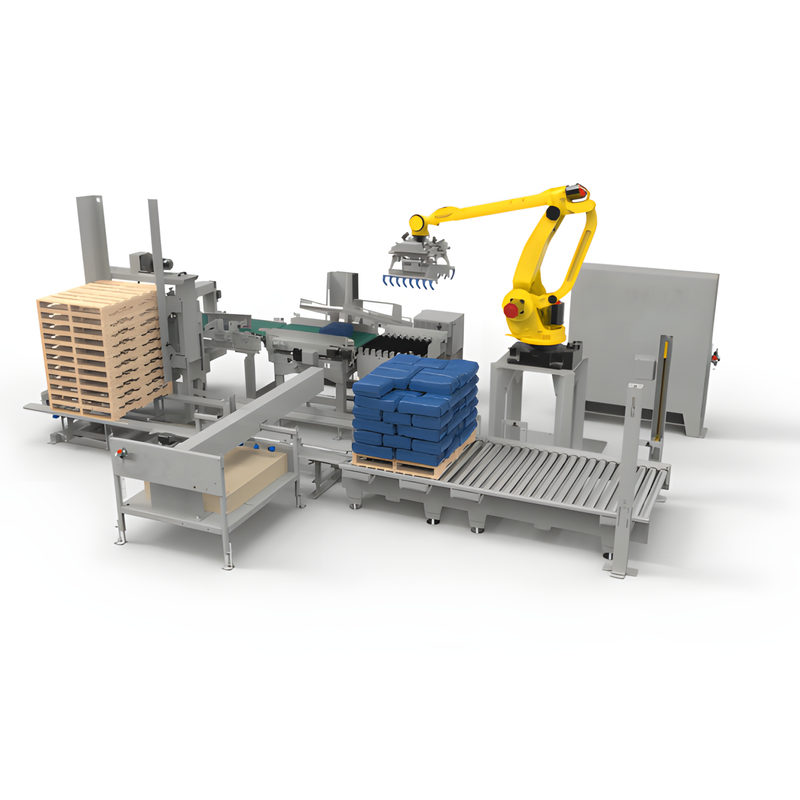

The AutoStack Pro-X Robotic Palletizing System revolutionizes end-of-line packaging automation by combining power, flexibility, and intelligence. Built for high-throughput environments, it integrates a high-payload robotic arm, a dual-function end effector, and a smart control system capable of managing multiple conveyors and pallet zones. Designed to eliminate manual palletizing labor, it enhances workplace safety, operational consistency, and ROI across industrial sectors including food & beverage, logistics, pharmaceuticals, and manufacturing.

Applications

| Industry | Application | Benefits |

| Food & Beverage | Palletizing cartons of bottled water, juice, or canned goods | Increased throughput, reduced injury risk |

| Logistics/Warehousing | Multi-SKU palletizing from various conveyors | Flexible handling of different box sizes |

| Pharmaceuticals | Cartonizing and palletizing of boxed medications | Gentle handling, compliance with hygiene standards |

| Consumer Goods | Automated stacking of packaged items into custom pallets | SKU variability, minimized labor needs |

| Manufacturing | Handling heavy or irregular parts in bulk packaging | High payload capacity, rugged design |

Product Features

Dual-Function Custom End Effector for Seamless Material Handling

The AutoStack Pro-X features an advanced custom-built two-in-one end effector capable of picking up both carton boxes and empty pallets without requiring tool changeover. This innovation dramatically reduces cycle time and downtime, boosting overall palletizing efficiency. The gripper system uses vacuum suction for cartons and a mechanical clamp or hook system for pallets, ensuring secure handling every time.

Multi-Line & Multi-Zone Operation with Intelligent Routing

The integrated control software allows the system to manage up to four incoming conveyor lines and multiple pallet zones simultaneously. Equipped with advanced sensors and vision capabilities (optional), the robot dynamically identifies incoming box types and assigns them to the correct palletizing pattern. This ensures precision stacking even with mixed SKUs and varying box dimensions.

Product parameters

| Parameter | Specification |

| Robot Arm Payload | Up to 180 kg |

| Max Palletizing Height | 2,400 mm |

| Max Box Dimensions | 800 x 600 x 600 mm |

| Conveyor Compatibility | Up to 4 independent lines |

| Pallet Zones | 1 to 6 configurable pallet locations |

| End Effector Type | Dual-function (pallet & box handling) |

| Cycle Time | < 8 seconds per pick |

| Control Interface | Touchscreen HMI + PLC + Safety Interlock |

| Power Supply | 400V / 3 Phase / 50-60Hz |

| Optional Add-ons | Vision system, safety fence, remote access |

Customer Case

Beverage Bottling Plant

E-commerce Distribution Center

Pharmaceutical Manufacturer

FAQ

1. What types of boxes or cartons can the system handle?

The system handles a wide range of box sizes, materials (corrugated, plastic, etc.), and weights up to 50kg per unit. Custom grippers are available for unusual shapes.

2. Can it handle multiple pallet types and sizes?

Yes, the AutoStack Pro-X supports Euro, CHEP, and custom pallet dimensions. The system can also automatically switch between pallet types during operation.

3. How long does installation and commissioning take?

Typically, installation and full system commissioning take between 2 to 4 weeks, depending on complexity and site readiness.

4. Is it easy to reprogram for new products?

Yes. The system includes an intuitive HMI and software interface that allows operators to add or modify palletizing patterns with minimal training.

5. What safety features are included?

The system comes with emergency stop buttons, safety fencing, area scanners, and light curtains. It complies with CE and ISO 10218-1 robotic safety standards.