Product Description

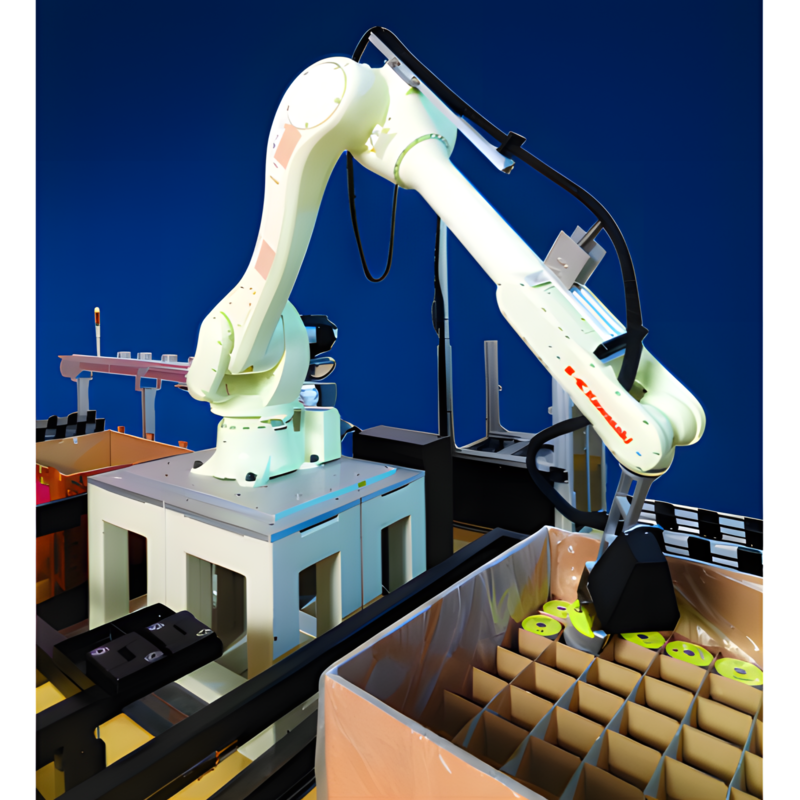

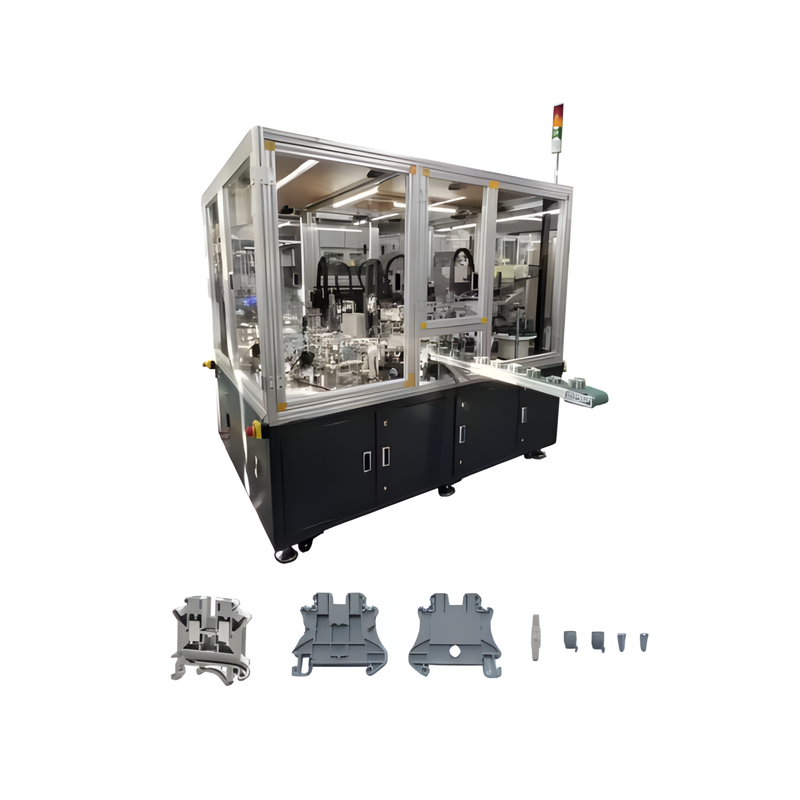

The IntelliPack-RX™ is an advanced robotic automation system engineered for high-speed, high-accuracy packaging operations. By integrating state-of-the-art robotic arms, customizable grippers, and machine vision inspection, the system ensures consistent performance, minimized manual intervention, and full traceability of packed items. Whether handling fragile components or variable-sized products, IntelliPack-RX™ delivers unmatched efficiency, reduced operational costs, and automated compliance with traceability requirements. Ideal for industries seeking a scalable, smart, and error-free packing process.

Application

| Industry | Use Case | Benefit |

| Electronics | Component packing with lot tracking | Prevents missing/mixed parts, traceability |

| Pharmaceuticals | Packing fragile ampoules or medical kits | Damage-free handling and full QA logs |

| Consumer Goods | High-volume packaging of varied SKUs | Fast throughput with zero rework |

| Automotive | Kit packing for parts and assemblies | Ensures completeness and part accuracy |

| E-commerce | Custom order fulfillment | Reduces packing errors, increases speed |

Product Features

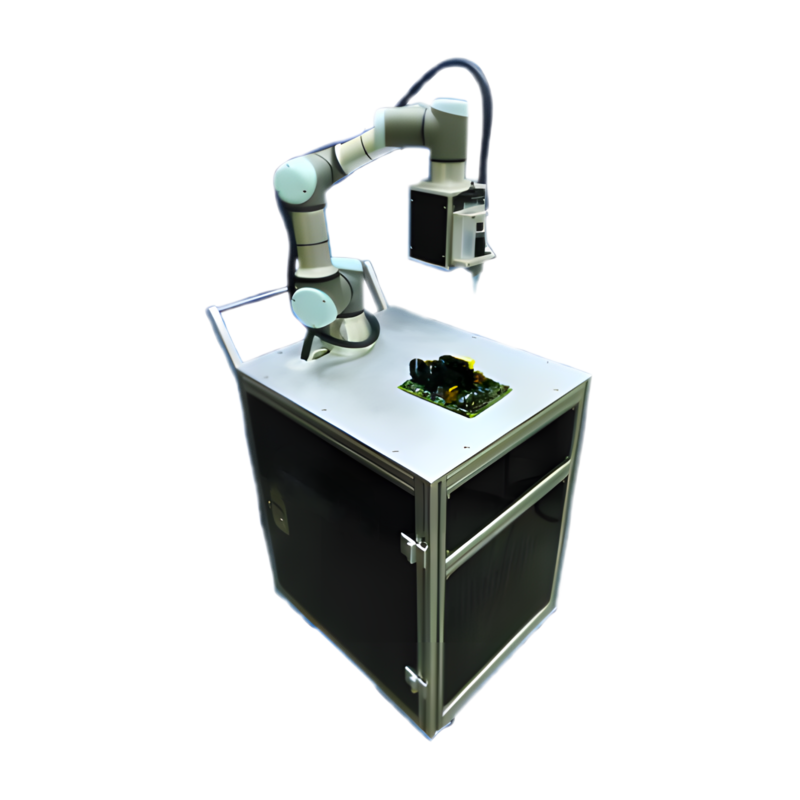

Machine Vision with Intelligent Inspection & Traceability

The system incorporates a high-resolution machine vision module that performs real-time inspection of items on the packing line. It checks for product integrity, verifies correct placement, and captures lot codes for each item. This information is automatically uploaded to a server, allowing traceability from packaging to delivery.

Benefits:

Eliminates packing errors such as mixed or missing parts

Supports quality audits with captured images and lot data

Enables instant recall tracking in regulated industries

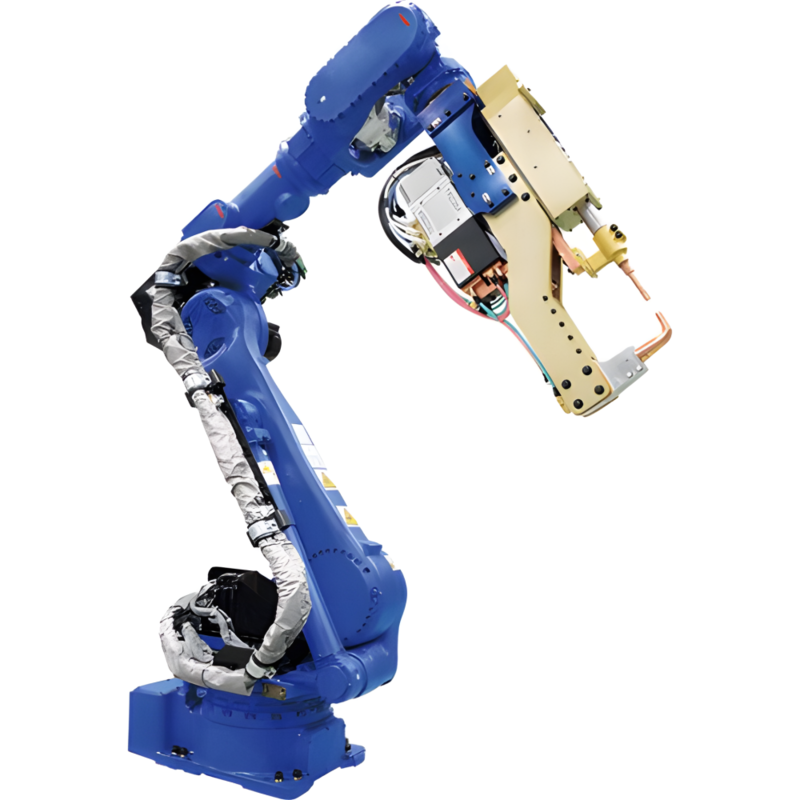

Smart Gripper System for Multi-Shape Product Handling

The IntelliPack-RX™ uses a modular, servo-driven gripper that adapts to varying product dimensions and fragility. Whether packing glass vials or irregular plastic components, the gripper applies appropriate pressure, ensuring zero damage and aligned placement.

Benefits:

Handles product variability with no need for manual changeover

Prevents surface scratches or crushing of delicate goods

Ensures gentle placement with millimeter precision

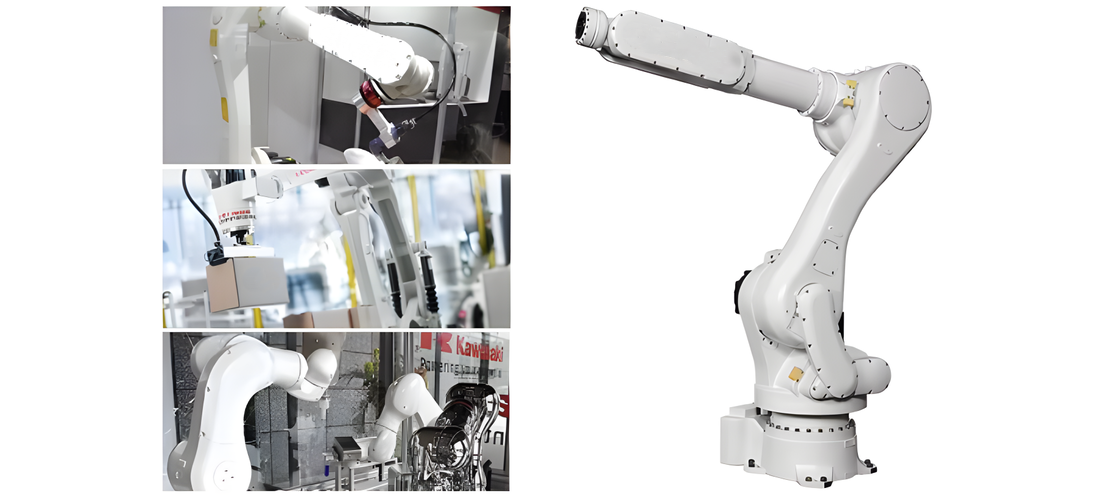

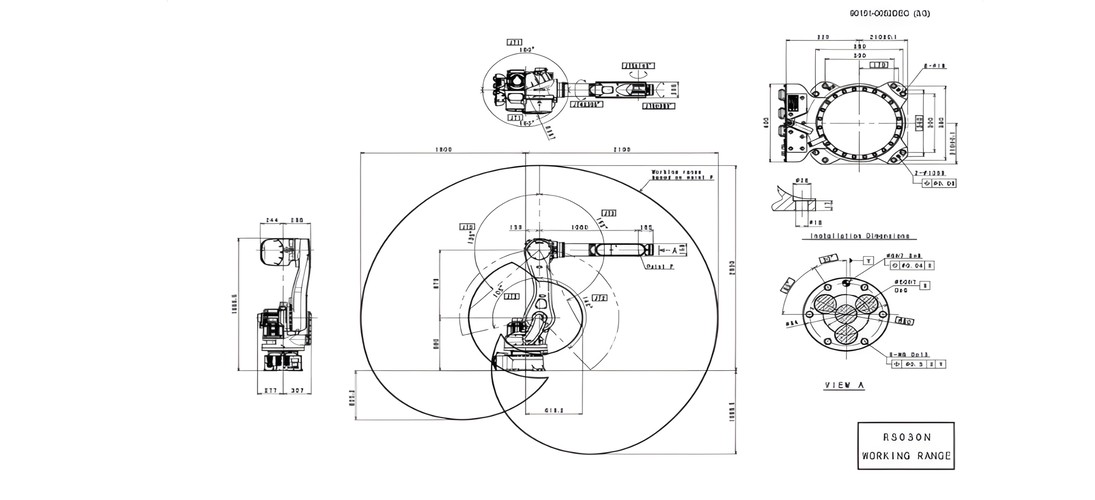

Structure Diagram

Product parameters

| Specification | Value |

| Robot Speed | Up to 120 picks/minute |

| Vision System Resolution | 5MP industrial camera, real-time FPS |

| Gripper Type | Customizable multi-jaw pneumatic/servo |

| Conveyor Integration | Compatible with standard and modular conveyors |

| Lot Tracking Capability | OCR, barcode, and datamatrix capture |

| Data Upload Protocol | MQTT, OPC-UA, or RESTful API |

| Control System | PLC + HMI with remote monitoring |

| Power Supply | 220V AC, 50/60Hz |

| Operating Environment | 10–45°C, Non-condensing |

Customer Case

High-Speed Medical Kit Packaging with Lot Code Compliance

E-commerce Order Fulfillment with Vision-Based Accuracy

Automotive Component Kit Packing with QA Record Integration

FAQ

1. Can the IntelliPack-RX™ handle products of different sizes on the same line?

Yes. The modular gripper and dynamic vision system allow for handling a wide range of product shapes and sizes without manual changeovers.

2. What types of lot tracking formats are supported?

It supports OCR, 1D barcodes, and 2D codes like DataMatrix and QR, with auto-capture and server upload.

3. How difficult is system integration into existing lines?

IntelliPack-RX™ is designed for plug-and-play integration with standard PLCs and conveyors, minimizing installation time.

4. Is the system suitable for fragile or easily damaged items?

Absolutely. The customizable gripper ensures soft contact handling, ideal for glassware, electronics, or delicate materials.

5. What is the maintenance requirement for the robot and vision systems?

The system requires minimal maintenance, mainly consisting of routine checks on the gripper, lens cleaning, and software updates. Remote diagnostics are also available.