Product Description

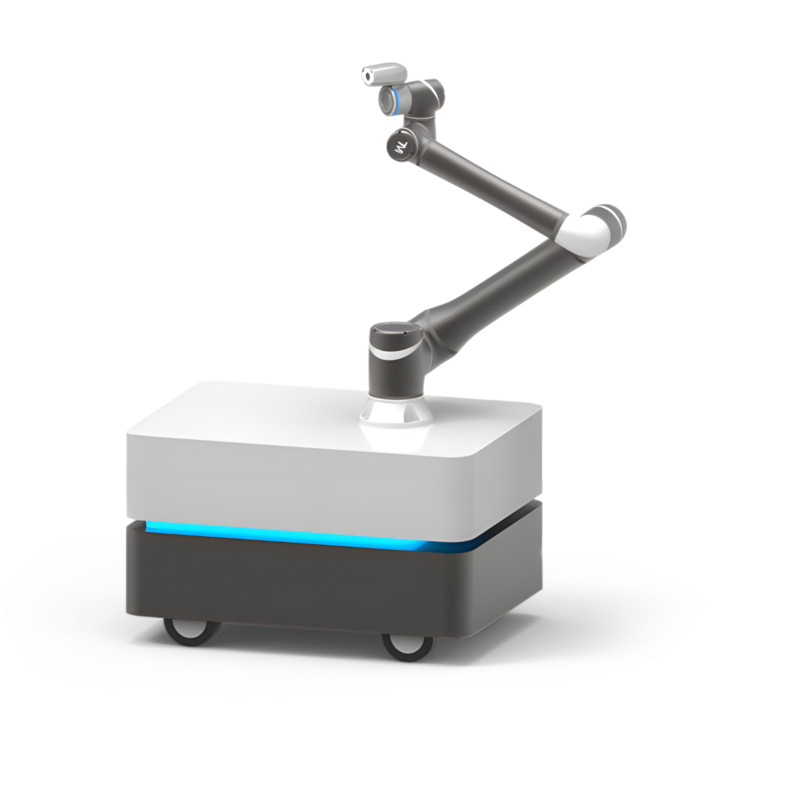

The Cobot Dispensing System is an advanced fluid application solution that combines the flexibility of collaborative robotics with the precision of automated dispensing. Engineered for high-accuracy operations on complex part geometries, this system features a dispenser head mounted on a cobot end-effector, integrated vision technology for real-time calibration, and quick-changeover support for high-mix manufacturing environments. It eliminates the need for dedicated fixtures or jigs, making it ideal for flexible production lines and small-batch or custom runs.

Applications

| Industry | Application Area | Examples |

| Electronics | Conformal coating, solder paste, adhesive dots | PCB coating, component bonding |

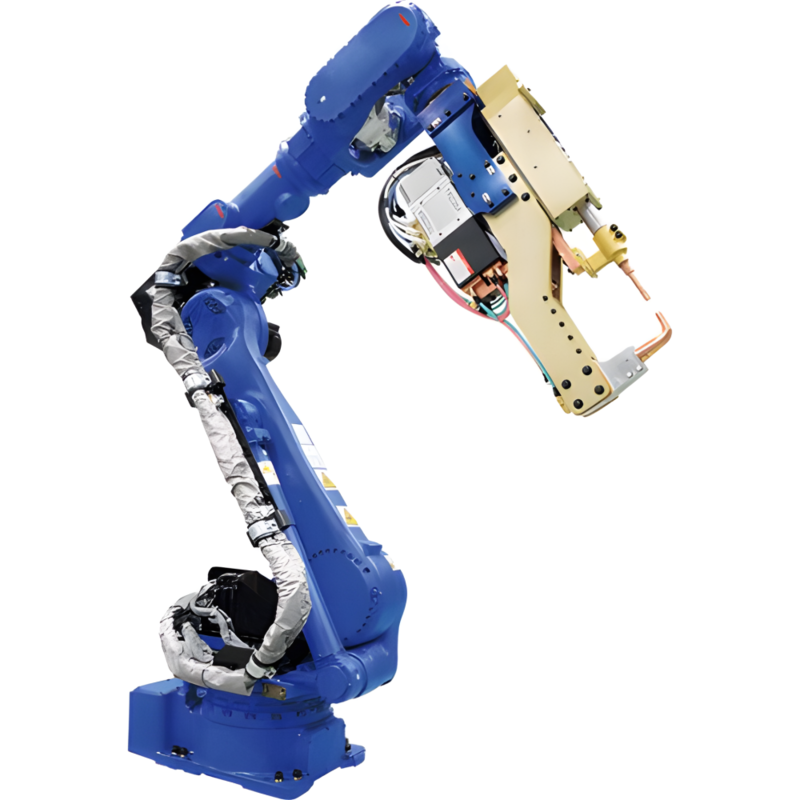

| Automotive | Gasket dispensing, sealants | EV battery sealing, headlight assembly |

| Medical Devices | Bio-compatible adhesives | Catheter bonding, tube sealing |

| Consumer Products | Cosmetic packaging, micro-dosing | Perfume bottle capping, lotion dispensing |

| Aerospace | Precision sealing and bonding | Fuel cell gaskets, structural adhesive applications |

Product Features

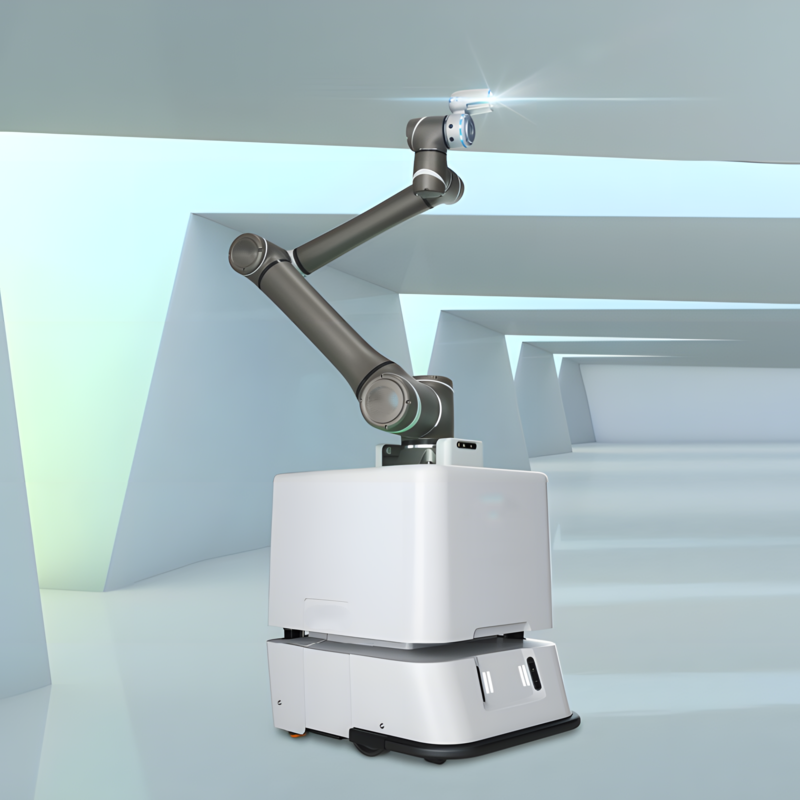

Integrated Vision System with Auto Calibration

The built-in camera system enables the cobot to automatically calibrate and adjust its dispensing path. Whether part positions shift or geometries vary, the vision module ensures dynamic correction without manual intervention. This increases accuracy and reduces waste due to misalignment.

Tool-Free Quick Changeover for High-Mix Production

With a tool-free end-effector interface and software-guided changeover process, the system enables rapid switching between products. Ideal for high-mix, low-volume production, it significantly reduces downtime and setup complexity, improving manufacturing agility.

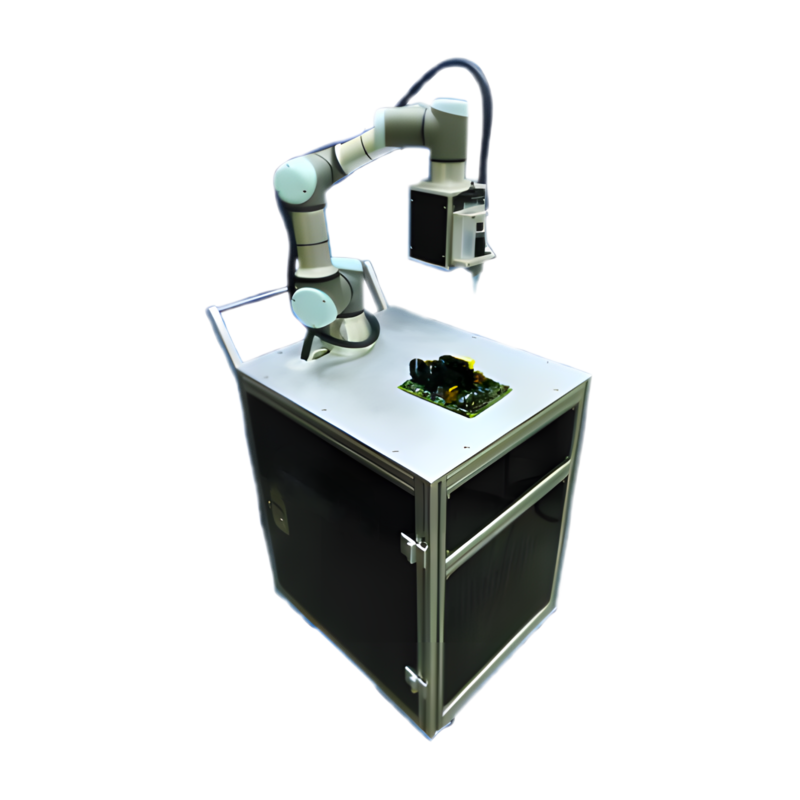

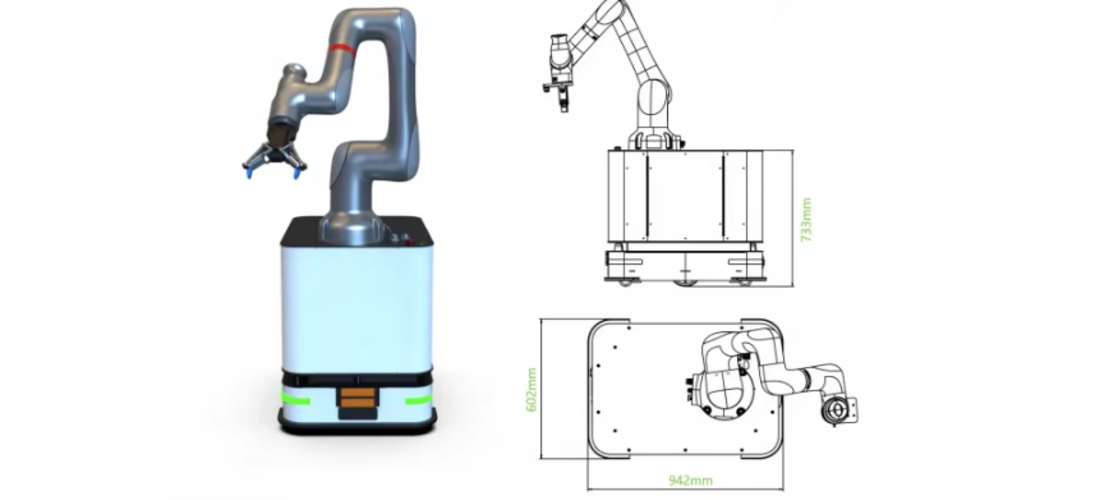

Structure Diagram

Product parameters

| Parameter | Specification |

| Dispensing Medium | Adhesives, sealants, lubricants, coatings |

| Compatible Robot Models | UR5e, UR10e, Doosan M1013, FANUC CRX, etc. |

| Vision System | 2D camera with auto-offset & edge detection |

| Positional Accuracy | ±0.2 mm (application-dependent) |

| Maximum Dispense Rate | Up to 30 mL/min (depending on fluid & tip size) |

| End-Effector Interface | Universal mount, quick-swap adapter |

| Control Interface | URCap / ROS / Custom API / PLC via Modbus/TCP |

| Power Supply | 24V DC (Robot supplied or external) |

Customer Case

PCB Conformal Coating for Electronics Manufacturer

Battery Sealant Application in Electric Vehicles

Custom Packaging Adhesive Application

FAQ

1. Does the system support different types of fluids?

Yes, it supports a wide range of materials including adhesives, sealants, greases, lubricants, and low-viscosity coatings. Customization may be required for highly reactive or abrasive materials.

2. Can I use my existing collaborative robot?

Yes, the dispensing head is designed to be compatible with most leading cobot brands such as Universal Robots, Doosan, and FANUC. A mounting kit and integration guide are provided.

3. How does the vision system work with part variations?

The integrated 2D vision system detects part edges and key landmarks to auto-correct the dispensing path in real-time. This ensures accuracy even with misaligned or irregular parts.

4. Is programming required for each new part?

Minimal programming is needed. The system includes a user-friendly interface with teach-by-demonstration features and pre-set templates for common applications.

5. What maintenance is required?

Routine maintenance includes cleaning the dispenser tip, checking fluid lines for clogs, and updating software as needed. The system includes alerts and diagnostics to aid preventive maintenance.