Product Description

Sheet metal processing refers to a processing process for sheet metal (usually less than 6mm), including cutting, bending,

stamping, welding and other processes. This processing method is widely used in manufacturing, such as automotive, aviation, electronics, electrical appliances and other fields.

Our products has the following characteristics:

1. High precision: The precision of product is very high and can be controlled at the millimeter level.

2. Lightweight: We can process sheet metal into lightweight structures, thereby reducing weight and increasing productivity.

3. Diversify: We can produce a variety of products through different combinations of processes and materials.

4. High efficiency: Products can be automated and continuous production, thereby improving production efficiency.

Product parameters

| List | Details |

|---|---|

| Product name | Sheet Metal Fabrication Stamping Bending Welding Turning Parts |

| Material | Stainless Steel Carbon Steel Aluminum |

| Process | Laser Cutting Bending Stamping Welding |

| Surface treatment | Painting \ Powder Coating \ Plating \ Polishing |

| Service | Customized OEM |

| Application | Industry |

| Type | OEM Sheet Metal Fabrication Parts |

| Single package size | 20X15X10 cm |

| Single gross weight | 5 kg |

Custom Process

1. Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Material

Aluminum alloy

Metal Sheet

Copper Sheet

Brass Sheet

Quality Control

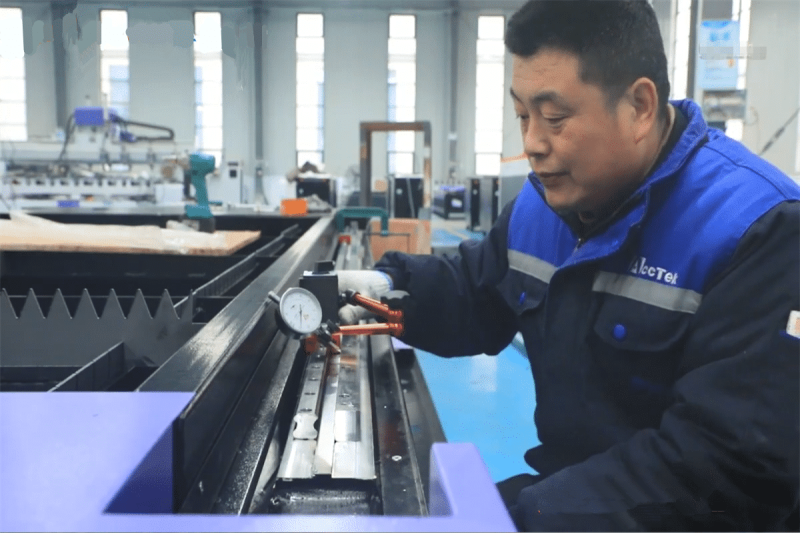

QC in Laser Cutting

1. Precision and Accuracy

One of the primary quality control measures for laser cutting is ensuring that the cuts are made with the required tolerances

2. Edge Quality

QC involves inspecting the edges of the cut material for smoothness, lack of burrs, and uniformity

3. Cutting Speed and Material Interaction

The laser’s power settings, cutting speed, and the material being cut must be carefully controlled to prevent issues like excessive heat-affected zones (HAZ), which could weaken the material or cause warping

4. Material Waste and Efficiency

QC also focuses on minimizing material waste

5. Automated Inspection

Many CNC lasers cutting systems integrate automated inspection systems, such as vision cameras or laser scanners, to monitor the quality of cuts in real time.

Processing capability

Laser Cutting Processing Capability

Laser cutting is a precise and efficient method used in CNC (Computer Numerical Control) machines to cut, engrave, or etch materials like metal, plastic, wood, and composites. This process uses a high-powered laser beam to melt, burn, or vaporize the material, creating an extremely clean cut with minimal heat-affected zones. The processing capability of laser cutting in CNC robots refers to the machine's ability to handle different types of materials, thicknesses, and cut qualities.

Additional processes

Welding Processing Capability

Welding in CNC robots involves the automated joining of two or more materials, typically metals or thermoplastics, using heat and/or pressure to form a strong bond. In CNC robotic welding, the robot is programmed to control the welding torch or electrode, ensuring precise movement and positioning during the welding process.