产品描述

小尺寸是微型电动平行夹持器的显著特点之一。这使得它可以在空间有限的环境中灵活使用,例如小型自动化设备,微型机器人等。

三面安装设计进一步增强了夹持器的灵活性和适应性。用户可根据实际需要选择不同的安装面,使夹爪与设备更好的结合。

网络应用功能允许多个微型电动平行抓手一起工作,以实现更复杂的任务。通过网络连接,可以实现夹持钳爪之间的信息交换和协调动作,提高工作效率和精度。在大型自动化生产线中,网络化应用可以实现多工位的同步操作,提高生产的整体效率。同时,网络应用也可以很容易地集中控制和管理,降低维护成本。

产品参数

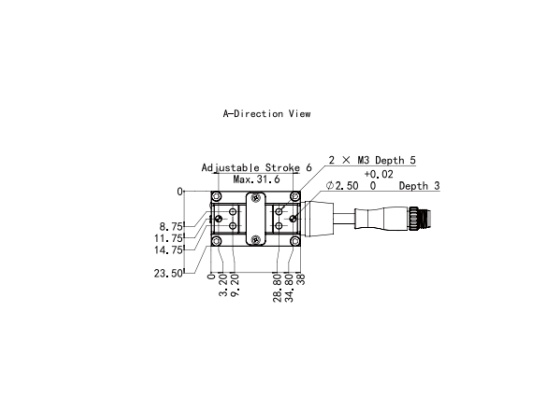

| 行程 | 6mm |

| 单指夹持力 | 6/15 N两档可调 |

| 打开/闭合时间 | 0.2s |

| 位置重复精度 | ±0.02 mm |

| 推荐最大负载 | 0.3 Kg |

| 本体重量 | 0.2kg |

| 控制方式 | Digital l/O |

技术创新

服务于医疗自动化、锂电池、3C、半导体、食品等行业数十家标杆企业。特别是针对医疗行业的试管开孔、扫码等工艺开发的夹持旋转一体化电动夹持器,为医疗行业提供了完美的解决方案。做出联系贡献。

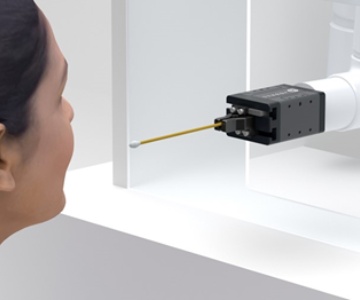

产品展示

适用于对精度要求高、空间有限的小型零部件抓取和装配,如电子元器件生产、小型精密机械加工等领域。

夹持面平行且对称,通过电动驱动实现精准开合,结构设计精巧,操作灵活,能适应各种形状和尺寸的工件,可快速准确地夹取和放置工件,减少人工操作复杂性和出错率,提高生产效率,且夹持力均匀稳定,可避免工件损伤。

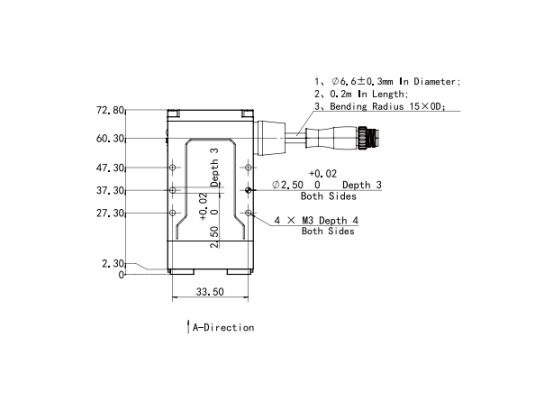

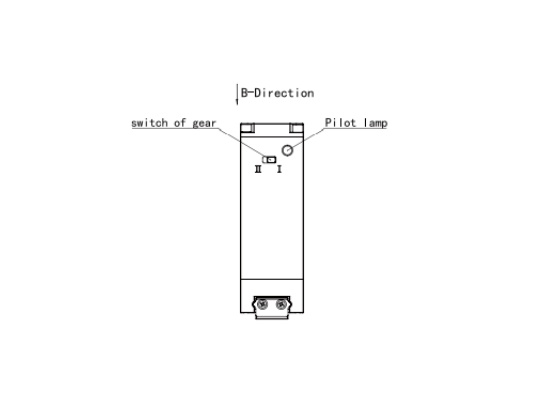

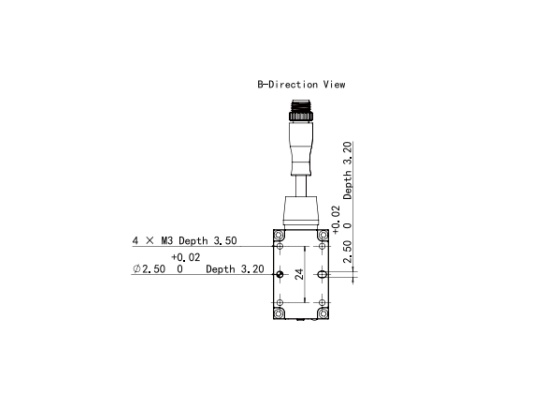

尺寸和接口

产品特性

圆柱形电池芯的抓取

高精度的特性使夹持器能够准确地定位和抓取圆柱形电池单体。圆柱形电池通常对抓握精度要求较高,稍有偏差就可能影响后续生产工艺或产品质量。

圆柱形电池芯具有一定的重量和硬度,并且需要来自夹钳的稳定夹紧力。高精度电动平行夹持器可根据电池芯的尺寸和重量自动调整夹持力,确保在抓取过程中不会因压力过大而导致电池芯打滑或损坏。

在实际生产中,圆柱形电池的尺寸可能会有所不同。高精度电动平行夹持器通常具有一定的调节范围,可以适应不同直径和长度的圆柱形细胞。

高精度电动平行夹爪可轻松与自动化生产线集成,实现全过程自动化生产。通过与其他设备的配合,可以完成生产线上电池的抓取、运输、组装等任务。

应用案例

在电缆加工行业中,平行夹钳可以实现电缆的快速剥离。夹爪的高精度和可调节性使其能够适应不同直径的电缆,准确地夹紧和剥离电缆护套。夹钳的使用可以提高剥线的效率和质量,也可以与自动化剥线设备配合使用。结合实现电缆剥线的全自动化生产。

在实验室中,平行夹钳可以方便地打开和关闭试管。它能准确夹紧试管盖,方便地打开或关闭试管,避免人工操作可能造成的试管破损或样品污染。对于需要频繁试管操作的实验,使用夹钳可以大大提高工作效率。

在喉道取样过程中,平行夹持器的高精度和稳定性至关重要,夹持器的操作可以通过自动化设备进行控制。