Product Description

Brush motor features and compact size

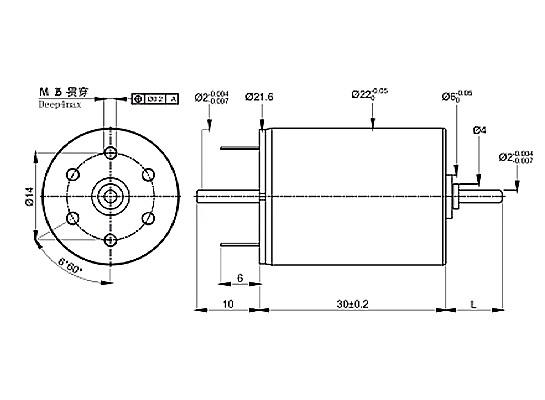

As a brush motor, it has certain advantages in structure. The combination of brush and commutator ensures the stable transmission of current, so that the motor can continue to run stably. Despite the brush design, the overall size is small, enabling efficient functional integration in a limited space. Its 22mm diameter and 30mm length make it easy to adapt to a variety of space-demanding equipment, providing an ideal power choice for the miniaturized design of equipment.

Product parameters

| Motor parameter | Motor type | ||||

|---|---|---|---|---|---|

| name | unit | XBD22300 6113HT- 20080 | XBD22301 2122HT- 20080 | XBD22301 B108HT 20080 | XBD22302 4110HT 20080 |

| Rated voltage | V/DC | 6 | 12 | 18 | 24 |

| Rated speed | rpm | 9492 | 10248 | 9234 | 9405 |

| Rated current | A | 0.88 | 0.63 | 0.42 | 0.29 |

| Rated torque | mi | 3.91 | 5.22 | 5.79 | 5.26 |

| No-load speed | rpm | 11300 | 12200 | 10800 | 11000 |

| No-load current | mA | 90 | 65 | 45 | 30 |

| Maximum efficiency | % | 75 | 74.9 | 75.4 | 75.8 |

| Rotational speed | rpm | 9944 | 10736 | 9558 | 9735 |

| Electric current | A | 0.679 | 0.489 | 0.339 | 0.234 |

| torque | mNm | 2.9 | 3.9 | 4.6 | 4.2 |

| Maximum power | W | 7.2 | 10.4 | 11.3 | 10.4 |

| Rotational speed | rpm | 5650 | 6100 | 5400 | 5500 |

| Electric current | A | 2.5 | 1.8 | 1.3 | 0.9 |

| torque | mNm | 12.2 | 16.3 | 20 | 18.1 |

| Locked-rotor current | A | 5 | 3.6 | 2.6 | 1.8 |

| Locked-rotor moment | mNm | 24.4 | 32.6 | 40 | 36.3 |

| Motor impedance | Ω | 1.2 | 3.33 | 6.92 | 13.33 |

| Inductive reactance of motor | mH | 0.19 | 0.403 | 0.85 | 1.6 |

| Torque constant | mNm/A | 4.98 | 9.22 | 15.64 | 20.49 |

| Speed constant | rpm/V | 1883.3 | 1016.7 | 600 | 458.3 |

| Revolution/torque constant | rpm/mNm | 462.2 | 374.2 | 270.3 | 303.3 |

| Mechanical time constant | ms | 13.05 | 11.08 | 7.9 | 9.09 |

| Rotor inertia | gcm2 | 2.7 | 2.83 | 2.79 | 2.54 |

Technological Innovation

High torque output

The outstanding performance of this motor is its high torque. With an optimized design and high-quality materials, the motor is able to generate powerful torque when driven by 12V voltage. This is like a small body but has a large strength of the lex, in the need for a large power drive in the application scenario, whether it is driving a large load of mechanical structures or need to overcome a certain resistance of the equipment, can easily cope.

Product Display

Stable operating performance

The rated voltage of 12V provides a stable power supply for the motor, and the mature technology of the brush motor ensures the stability of the motor during operation. The good coordination between the brush and the commutator makes the current transmission stable, the motor speed stable, and the fluctuation and jitter are reduced. This stability is like a ship sailing in a calm sea, no matter what kind of conditions, it can maintain reliable operation.

Good adaptability

Due to its structural and performance characteristics, this motor has good adaptability to different working environments and load conditions. Whether it is in a normal temperature environment or within a certain temperature range, whether it is light load or heavy load (within its design torque range), the motor can work normally, showing strong adaptability, like an all-rounder, can play its own strength under a variety of competition venues and rules.

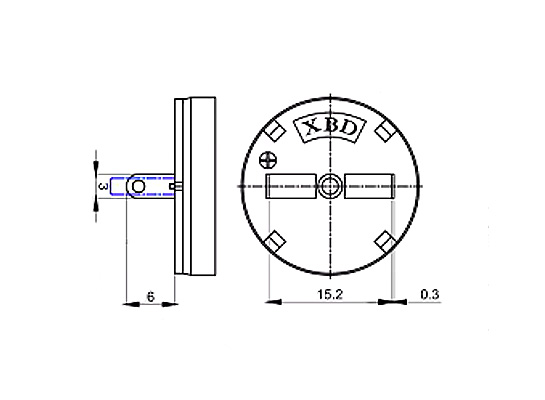

Size & Interface

Quality Control

Assembly link control: tight seam

The assembly process of the motor is like a precise jigsaw puzzle, where every component must be fitted into place without error. Our assembly workers are professionally trained, have rich experience and a high sense of responsibility. When assembling the hollow cup rotor, ensure that its position in the stator is accurate and the clearance with the brush and commutator is just right. The tightening torque of each screw is precisely calculated and strictly controlled to prevent the overall performance of the motor from being too tight or too loose. After the assembly is completed, the appearance of the motor is also carefully checked to ensure that no parts are loose, scratched or improperly assembled.

Performance testing: Comprehensive inspection

We have a set of perfect performance testing system, for each hollow cup brush motor for comprehensive and strict inspection. In terms of electrical performance detection, the starting current, no-load current, rated power, speed and torque of the motor are measured by high-precision test equipment to ensure that these parameters are within the specified tolerance range and meet the design requirements. For the mechanical properties of the motor, we simulate the actual working environment and carry out long-term operating tests to observe the vibration, noise level and heating degree of the motor. Only motors that are fully qualified in all performance indicators will be labeled as qualified in quality and enter the market.

Durability test

In order to ensure the reliability and life of the motor, we will carry out a long time durability test on the motor. In the simulation of various actual working conditions, the motor is continuously run for hundreds of hours, during which the performance indicators of the motor are continuously monitored, such as temperature changes, vibration conditions, electrical parameter stability, etc. Only motors that pass the durability test and have no significant degradation in performance will be considered qualified products.

Quality traceability system: Tracing to the source

In order to ensure the continuous stability of quality, we have established a sound quality traceability system. Each hollow cup brush motor has a unique identity, from the procurement batch of raw materials, all aspects of the production process data to the final test report, are recorded in detail. Once a quality problem is found, it can be quickly traced back to the root of the problem, and effective corrective measures can be taken to avoid the recurrence of similar problems.

Application Cases

Small robot field

In the small robot joint drive, walking mechanism and other parts, the characteristics of high torque can meet the needs of the robot in the process of movement. Its small size can also be perfectly adapted to the compact structure of the robot, so that the robot can flexibly complete various actions, such as grasping objects, moving and so on.

Precision instrument and equipment

For precision instruments that require precise control and require a certain torque drive, such as small optical adjustment frames, micromachining equipment, etc., the high torque and stability of the motor ensure high precision operation of the instrument and achieve precise control of small displacements and angles.

Model toy industry

In remote control model cars, model planes and other model toys, the motor can be used as the power core. The high torque allows the model to perform well during startup and acceleration, while its miniature size and stable operation characteristics meet the requirements of the model toy for lightweight and reliability, bringing the player a better handling experience.

Smart home device

In smart home equipment, such as the driving device of smart curtains, the mechanical transmission part of small smart door locks, etc., this motor can provide stable power for the equipment with its high torque and appropriate size, realize the automatic operation of the equipment, and improve the convenience of home life.

Cooperative partner

Service

Pre-sale service

Our dedicated sales team and technical experts know everything about motors. Before you buy, you will learn more about your application needs in industrial equipment such as winding machines, industrial saws, robotic arms or automatic weighing systems. According to these requirements, we will accurately introduce the performance parameters, advantages and how to perfectly fit your equipment. Whether it is about the motor's coreless brushless design features, 36V voltage adaptability, or speed torque and other performance questions, we can give clear and professional answers, so that you have a comprehensive understanding of the product before buying.

In-sale service

During the purchase process, we guarantee the convenience and security of the transaction. Each motor is rigorously tested and carefully packaged to ensure no damage during transportation. We work with quality logistics to deliver the motor to you in an accurate and timely manner. If there is any problem after receiving the motor, our customer service team will respond quickly and actively solve.

After-sales service

Installation Guide: Provides detailed installation guides, including text, pictures and videos, to guide you in installing the motor into industrial equipment. In case of difficulties, professional engineers can provide remote guidance to ensure smooth installation.

Use training: Provide your operators with use training, covering motor start-up, operation parameter adjustment, daily operation precautions, etc., to help them give full play to the motor performance and ensure the normal operation of the equipment.

Continuous support: We pay close attention to your experience and visit regularly to collect feedback. When you have new needs or improvement suggestions, we will be happy to serve you to ensure that your industrial production continues to be efficient.