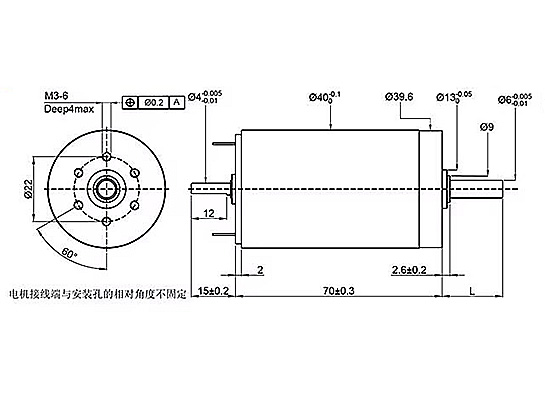

产品描述

这款大型号电机直径达 40mm、长度为 70mm,采用了先进的无芯设计。无芯电机的转子摒弃了传统铁芯结构,其独特的绕线方式形成了高度优化的转子构造。这种转子具有极低的转动惯量,如同身手敏捷的巨人,启动和停止速度极快,能在瞬间完成状态转换。在大型工业设备或需要高动态响应的应用场景中,这种特性可大幅提升设备的工作效率,有效减少启动和停止过程中的延迟时间。

产品参数

| 电机参数 | 电机型号 | |||||

|---|---|---|---|---|---|---|

| 名称 | 单位 | XBD40701 2082GT- 60205 | XBD40701 5076GT- 60205 | XBD40703 6075GT- 60205 | XBD40704 8076GT- 60205 | XBD40704 8022GT- 60205 |

| 额定电压 | V/DC | 12 | 24 | 36 | 48 | 48 |

| 额定转速 | rpm | 7585 | 7030 | 6900 | 6992 | 1606 |

| 额定电流 | A | 12.09 | 6.2 | 4.33 | 3.37 | 0.85 |

| 额定转矩 | mi | 161.41 | 181.25 | 189.36 | 196.86 | 172.37 |

| 空载转速 | rpm | 8200 | 7600 | 7500 | 7600 | 2200 |

| 空载电流 | mA | 500 | 180 | 180 | 100 | 18 |

| 最大效率 | % | 89 | 90.8 | 88.6 | 90.4 | 85.3 |

| 转速 | rpm | 7749 | 7258 | 7163 | 7258 | 2046 |

| 电流 | A | 8.998 | 3.794 | 2.512 | 1.941 | 0.234 |

| 转矩 | mNm | 18.4 | 108.8 | 106.5 | 110.7 | 44.7 |

| 最大功率 | W | 462 | 480.8 | 464.8 | 489.6 | 37 |

| 转速 | rpm | 4100 | 3800 | 3750 | 3800 | 1100 |

| 电流 | A | 77.8 | 40.3 | 26.1 | 20.6 | 2 |

| 转矩 | mNm | 1076.1 | 1208.3 | 1183.5 | 1230.4 | 319.2 |

| 堵转电流 | A | 155 | 80.5 | 52 | 41 | 3.1 |

| 堵转转矩 | mNm | 2152.1 | 2416.7 | 2367 | 2460.7 | 638.4 |

| 电机阻抗 | Ω | 0.08 | 0.3 | 0.69 | 1.17 | 15.5 |

| 电机感抗 | mH | 0.016 | 0.083 | 0.18 | 0.34 | 4.08 |

| 转矩常数 | mNm/A | 13.93 | 30.09 | 45.68 | 60.16 | 207.1 |

| 转速常数 | rpm/V | 683.3 | 316.7 | 208.3 | 158.3 | 45.8 |

| 转数/转矩常数 | rpm/mNm | 3.8 | 3.1 | 3.2 | 3.1 | 3.4 |

| 机械时间常数 | ms | 5.6 | 4.42 | 4.3 | 4.05 | 4.31 |

| 转子惯量 | gcm2 | 140.23 | 134.1 | 137.14 | 125.21 | 119.52 |

产品特性

低噪声与低振动

无芯电机结构有效地减少了振动和噪声的产生。由于没有铁芯在磁场变化时产生的振动源,再加上精心设计的转子平衡和电机内部的减震措施,电机在运行过程中产生的噪声和振动极低。这在对环境噪音要求严格的工业环境或需要高精度操作的设备中具有重要意义,如在精密制造车间、医疗设备制造等领域,能够避免因电机振动和噪音对生产过程或设备性能造成的不良影响。

产品展示

高效率运行

作为一款高效率的 24V 无芯电机,其核心价值在于卓越的能量转换效率。无芯结构从根本上消除了铁芯所带来的磁滞损耗和涡流损耗,就像为电能转化为机械能开辟了一条绿色通道。在实际应用中,这种高效率意味着更少的能源消耗和更低的运行成本。无论是连续长时间运行的大型工业生产线,还是对功率要求苛刻的重型机械设备,该电机都能以高效的性能将电能充分利用,为设备提供强劲且稳定的动力支持。

高功率密度

此电机在较大的尺寸下实现了高功率密度。通过优化设计和先进的制造工艺,它能够在有限的体积内输出强大的功率。这一特点使其在大型工业设备中具有独特的优势,例如在大型起重机、输送带驱动系统等需要大功率驱动的应用场景中,能够以较小的体积满足高负载的动力需求,有效节省设备空间,提高设备的整体性能和可靠性。

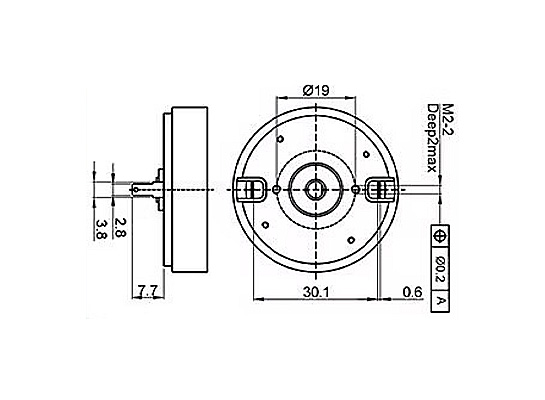

尺寸和接口

品控

- 装配环节把控:严丝合缝

电机的装配过程就像一场精密的拼图游戏,每一个部件都必须准确无误地安装到位。我们的装配工人都经过专业培训,具备丰富的经验和高度的责任心。在装配空芯杯转子时,要确保其在定子中的位置精准,与电刷和换向器的配合间隙恰到好处。每一颗螺丝的拧紧力矩都经过精确计算和严格控制,防止因过紧或过松而影响电机的整体性能。在装配完成后,还会对电机的外观进行细致检查,确保没有任何零部件松动、划伤或装配不当的情况。

- 性能检测:全面检验

我们拥有一套完善的性能检测系统,对每一台空芯杯有刷电机进行全面而严格的检验。在电气性能检测方面,通过高精度的测试设备测量电机的启动电流、空载电流、额定功率、转速和转矩等参数,确保这些参数都在规定的公差范围内,并且符合设计要求。对于电机的机械性能,我们模拟实际工作环境,进行长时间的运行测试,观察电机的振动情况、噪音水平和发热程度。只有在所有性能指标都完全合格的电机,才会被贴上质量合格的标签,进入市场。

- 耐久性测试

为了确保电机的可靠性和寿命,我们会对电机进行长时间的耐久性测试。在模拟各种实际工作条件下,让电机连续运行数百小时,期间不间断地监测电机的各项性能指标,如温度变化、振动情况、电气参数稳定性等。只有通过耐久性测试且性能无明显下降的电机才会被认为是合格产品。

- 质量追溯体系:追根溯源

为了确保品质的持续稳定,我们建立了完善的质量追溯体系。每一台空芯杯有刷电机都有唯一的身份标识,从原材料的采购批次、生产过程中的各个环节数据到最终的检测报告,都被详细记录在案。一旦发现质量问题,可以迅速追溯到问题根源,采取有效的纠正措施,避免类似问题的再次发生。

应用案例

- 工业自动化生产线

在自动化生产线上,这款电机可作为关键的动力驱动单元。无论是用于驱动传送皮带、机械臂关节,还是各种加工设备的主轴,其高效率、高功率密度和优秀的调速性能都能满足生产线不同环节对动力的精确要求。能够保证生产线的高效、稳定运行,提高生产效率和产品质量。

- 大型机械设备

对于大型起重机、挖掘机等重型机械设备,电机的高功率输出和大扭矩特性能够满足其在起吊重物、挖掘作业等高强度工作中的动力需求。同时,其低噪声和低振动特点有助于提高操作人员的工作舒适度,减少设备因振动而产生的磨损,延长设备使用寿命。

- 新能源领域

在一些新能源相关的设备中,如大型风力发电机的变桨控制系统、太阳能跟踪系统等,电机的高精度调速和高可靠性能够确保这些设备准确地调整角度,以获取最佳的风能或太阳能利用效率。其高效率特性也有助于降低整个新能源系统的能耗,提高能源转换效率。

- 物流与仓储设备

在物流自动化系统中,如自动导引车(AGV)、大型货架的升降设备等,电机的快速启动和停止能力、高效运行特性以及良好的调速性能,能够实现货物的快速、准确搬运和存储,提高物流效率,降低运营成本。

合作伙伴

服务

售前服务

我们的专业销售团队和技术专家对电机了如指掌。在您选购前,会详细了解您在绕线机、工业锯床、机械臂或自动称重系统等工业设备中的应用需求。根据这些需求,为您准确介绍电机的性能参数、优势以及如何完美适配您的设备。无论是关于电机的无芯无刷设计特点、36V 电压适应性,还是转速扭矩等性能问题,我们都能给予清晰、专业的解答,让您在购买前对产品有全面认识。

售中服务

购买过程中,我们保证交易的便捷与安全。每台电机都经过严格检测和精心包装,确保在运输过程中不受损。我们与优质物流合作,准确、及时地将电机送到您手中。收到电机后若有任何问题,我们的客服团队会迅速响应,积极解决。

售后服务

- 安装指导:

提供详细的安装指南,包括文字、图片和视频,指导您将电机安装到工业设备中。如有困难,专业工程师可远程指导,确保安装顺利。

- 使用培训:

为您的操作人员提供使用培训,内容涵盖电机的启动、运行参数调整、日常操作注意事项等,帮助他们充分发挥电机性能,确保设备正常运行。

- 持续支持:

我们长期关注您的使用体验,定期回访收集反馈。您有新需求或改进建议时,我们会竭诚为您服务,保障您的工业生产持续高效。