Product Description

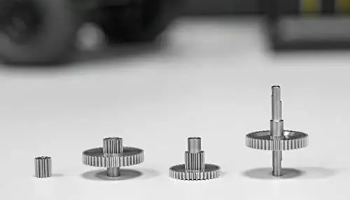

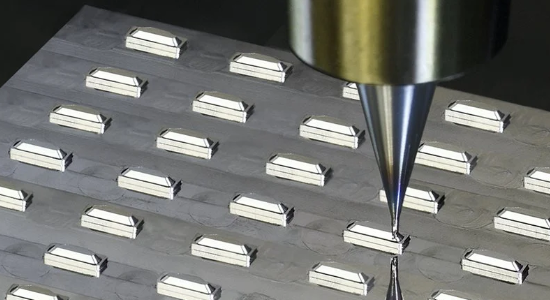

We specialize in producing high-precision machined products, utilizing advanced manufacturing techniques and state-of-the-art equipment to ensure exceptional accuracy and reliability. Our team is committed to delivering gears that meet the most stringent industry standards, with precision-engineered components tailored to the specific needs of our clients. Whether for automotive, aerospace, or industrial applications, we guarantee consistent quality and performance in every product we manufacture.

Product parameters

| Material | Aluminum (6061-T6, 6063, 7075-T6,5052) etc... Brass/Copper/Bronze etc... Stainless Steel (302, 303, 304, 316, 420) etc... Steel (mild steel, Q235, 20#, 45#) etc... Plastic (ABS, Delrin, PP, PE, PC, Acrylic) etc... |

| Process | CNC Machining, CNC turning, CNC milling, CNC lathe machining, CNC boring, CNC grinding, CNC drilling etc... |

| Surface treatment | Clear/color anodized; Hard anodized; Powder-coating; Sand-blasting; Painting; Nickel plating; Chrome plating; Zinc plating; Silver/gold plating; Black oxide coating, Polishing etc... |

| Gerenal Tolerance (+/-mm) | CNC Machining: 0.005 Turning: 0.005 Grinding(Flatness/in2): 0.003 ID/OD Grinding: 0.002 Wire-Cutting: 0.002 |

| Certification | ISO9001:2008, ROHS |

| Production capacity | depend on complicacy of different products and the quantity |

| Experience | 20 years of CNC machining products 3 years of automation machine manufacturing |

| Packaging | Standard: pearl cotton and bubble bag, carton box and seal For large and big quantity: pallet or as per customers' requirement |

| Lead time | In general:7-15days |

| Term of Payment | T/T, Paypal, Trade Assurance etc... |

| Minimum Order | Comply with customer's demand |

Custom Process

1. Product Design

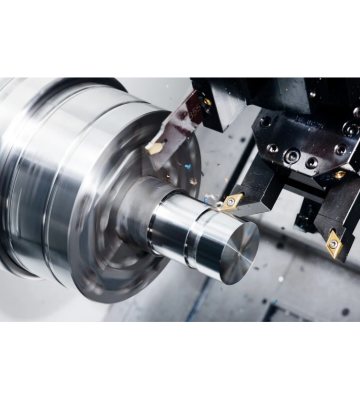

2. CNC Turning / Milling

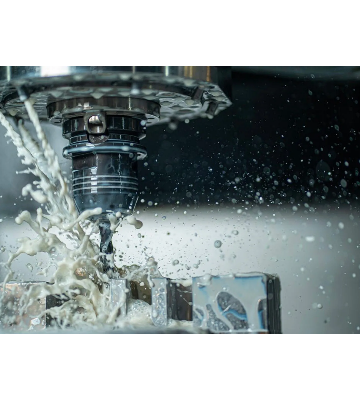

3. CNC Center

4. Quality Test

5. Package

6. Transportation

7. Use and Feedback

8. Win-win Cooperation

Process Type

Turning

Lathing

Gear detection

CNC Machining

CNC Milling Processing

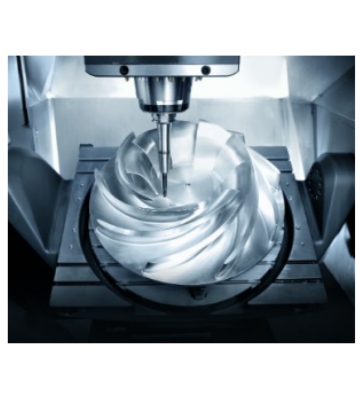

Five-axis Machining

Material

Aluminu Alloy

Stainless Steel

Aluminum-Alloy Block

Brass

Copper

Tube Material

Special Steel

Contact Us

Quality Control

Processing capability

Additional processes

Abrasive Jet Machining (AJM)

Applications: Commonly used for cleaning hard-to-reach areas, deburring sharp edges, or cutting fragile or soft materials like plastics or ceramics.

Key Benefits: Capable of producing fine finishes, good for fragile materials, and can be used for very intricate parts.

Micro-Machining

Applications: Microelectronics, medical devices, and aerospace components requiring extreme precision.

Key Benefits: Allows for the production of tiny, intricate parts with high precision.

Superfinishing

Applications: Often used for precision bearings, automotive crankshafts, and aerospace components

Key Benefits: Achieves exceptional surface finishes with very low roughness values, improves component performance, and extends the life of the parts.