Product Description

The hollow cup brush motor belongs to a kind of DC motor. Its rotor is a thin-walled hollow core cup-like structure, usually made of enameled wire woven and wound, shaped like a cup, hence the name. The stator of this kind of motor is a permanent magnet, and the motor has a brush and a commutator. The role of the brush is to contact the commutator and introduce the current of the external power supply into the rotor winding, and the commutator is responsible for changing the direction of the current in the course of the motor rotation, so that the rotor can continue to rotate.

Product parameters

| Motor parameter | Motor type | |||

|---|---|---|---|---|

| name | unit | XBD30456048GT-40100 | XBD304512078GT-40100 | XBD304524060GT-40100 |

| Rated voltage | V/DC | 6 | 12 | 24 |

| Rated speed | rpm | 4272 | 6942 | 5340 |

| Rated current | A | 0.77 | 1.4 | 0.49 |

| Rated torque | mi | 8.38 | 18.3 | 17.35 |

| No-load speed | rpm | 4800 | 7800 | 6000 |

| No-load current | mA | 60 | 140 | 35 |

| Maximum efficiency | % | 81.7 | 79.2 | 82.6 |

| Rotational speed | rpm | 4368 | 7020 | 5490 |

| Electric current | A | 0.64 | 1.286 | 0.389 |

| torque | mNm | 6.9 | 16.6 | 13.4 |

| Maximum power | W | 9.6 | 34 | 24.8 |

| Rotational speed | rpm | 2400 | 3900 | 3000 |

| Electric current | A | 3.3 | 5.9 | 2.1 |

| torque | mNm | 38.1 | 83.2 | 78.9 |

| Locked-rotor current | A | 6.5 | 11.6 | 4.2 |

| Locked-rotor moment | mNm | 76.2 | 166.3 | 157.8 |

| Motor impedance | Ω | 0.92 | 1.03 | 5.71 |

| Inductive reactance of motor | mH | 0.05 | 0.11 | 0.46 |

| Torque constant | mNm/A | 11.83 | 14.51 | 37.88 |

| Speed constant | rpm/V | 800 | 650 | 250 |

| Revolution/torque constant | rpm/mNm | 63 | 46.9 | 38 |

| Mechanical time constant | ms | 9.89 | 9.14 | 8.25 |

| Rotor inertia | gcm2 | 14.99 | 18.62 | 20.72 |

Product Display

High efficiency

The efficiency of the hollow cup brush motor is relatively high. Because the rotor is thin-walled hollow core structure, the moment of inertia is small, and it can respond quickly when starting and stopping, reducing energy loss. At the same time, this structure makes the electromagnetic conversion efficiency of the motor higher, and electrical energy can be converted into mechanical energy more effectively.

High speed of revolution

It can achieve a higher speed. The lightweight structure of the hollow cup rotor makes it easier to achieve a higher speed than the traditional motor under the same electromagnetic drive, which can generally reach tens of thousands of revolutions per minute, which is very advantageous in some equipment requiring high-speed rotation, such as small precision power tools.

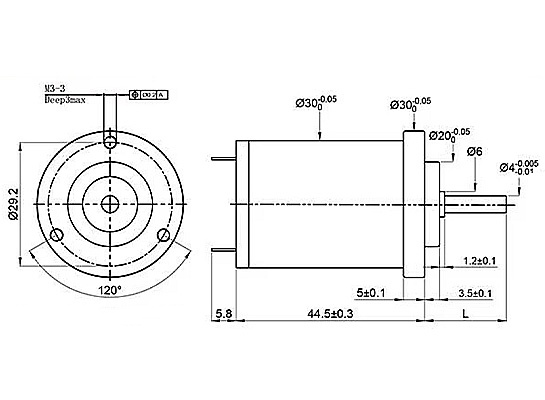

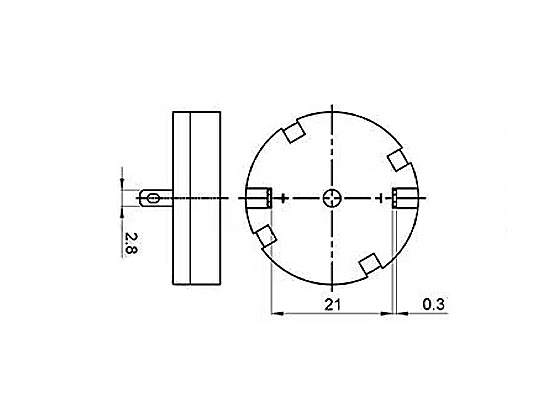

Size & Interface

Quality Control

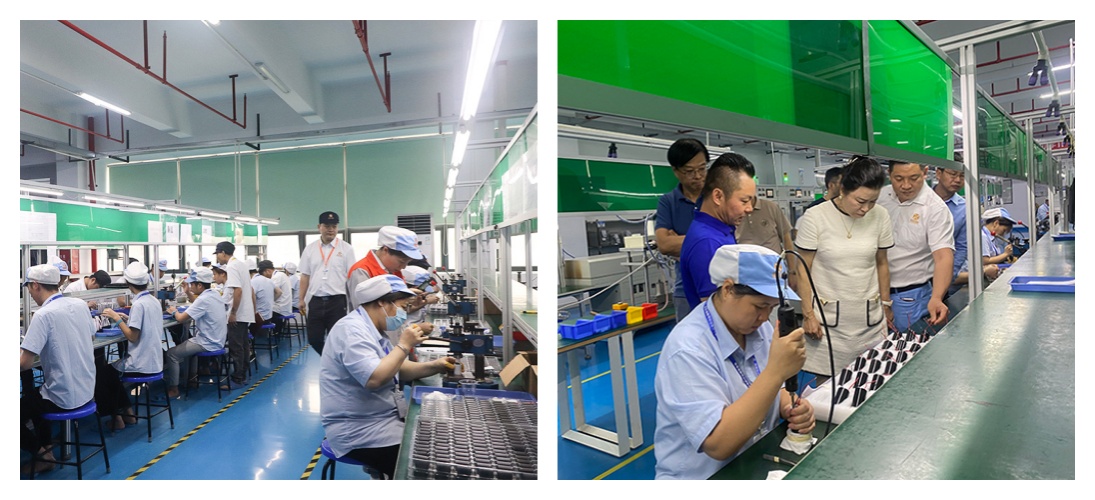

Assembly link control: tight seam

The assembly process of the motor is like a precise jigsaw puzzle, where every component must be fitted into place without error. Our assembly workers are professionally trained, have rich experience and a high sense of responsibility. When assembling the hollow cup rotor, ensure that its position in the stator is accurate and the clearance with the brush and commutator is just right. The tightening torque of each screw is precisely calculated and strictly controlled to prevent the overall performance of the motor from being too tight or too loose. After the assembly is completed, the appearance of the motor is also carefully checked to ensure that no parts are loose, scratched or improperly assembled.

Performance testing: Comprehensive inspection

We have a set of perfect performance testing system, for each hollow cup brush motor for comprehensive and strict inspection. In terms of electrical performance detection, the starting current, no-load current, rated power, speed and torque of the motor are measured by high-precision test equipment to ensure that these parameters are within the specified tolerance range and meet the design requirements. For the mechanical properties of the motor, we simulate the actual working environment and carry out long-term operating tests to observe the vibration, noise level and heating degree of the motor. Only motors that are fully qualified in all performance indicators will be labeled as qualified in quality and enter the market.

Durability test

In order to ensure the reliability and life of the motor, we will carry out a long time durability test on the motor. In the simulation of various actual working conditions, the motor is continuously run for hundreds of hours, during which the performance indicators of the motor are continuously monitored, such as temperature changes, vibration conditions, electrical parameter stability, etc. Only motors that pass the durability test and have no significant degradation in performance will be considered qualified products.

Quality traceability system: Tracing to the source

In order to ensure the continuous stability of quality, we have established a sound quality traceability system. Each hollow cup brush motor has a unique identity, from the procurement batch of raw materials, all aspects of the production process data to the final test report, are recorded in detail. Once a quality problem is found, it can be quickly traced back to the root of the problem, and effective corrective measures can be taken to avoid the recurrence of similar problems.

Application Cases

Hollow cup brush motor in many areas of excellence. In aerospace small UAVs, their lightweight, high-speed characteristics facilitate flight and photography. In the field of medical devices, such as handheld massagers and insulin pumps, low torque pulsation and precise control guarantee results. In products such as electric toothbrushes in consumer electronics, it offers a convenient experience with high RPM and small size.

Cooperative partner

Service

Our technical service team consists of a group of engineers with deep expertise and rich practical experience in the field of electrical machinery. They are familiar with the principle and structure of the hollow cup brush motor, whether it is the electromagnetic design of the motor, the hollow cup characteristics of the rotor, or the complex interaction between the brush and the commutator, they can be accurately analyzed. Whether it is a simple fault consultation or a complex technical problem, our engineers have the expertise to quickly provide accurate and effective solutions.