Product Description

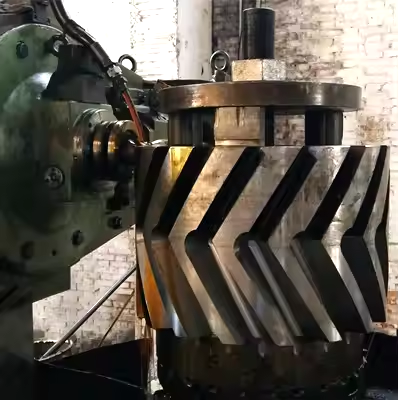

Stamping gear truck components involves shaping metal sheets into precision parts used in the transmission and drive systems of trucks. This process ensures high-volume production of durable, high-strength gears and related components with tight tolerances. Parts like gear blanks, shafts, and housings are commonly produced through stamping, offering reliability under heavy loads. The method is cost-effective and supports fast production cycles while maintaining part consistency. Careful quality control, including die design and material selection, is essential to ensure the gears' strength and performance. Advanced stamping techniques, such as progressive stamping, enable the creation of complex gear shapes with improved manufacturing efficiency.

Product parameters

| List | Details |

|---|---|

| Brand Name | Stamping gear |

| Purpose | for manufacturing |

| Application | Truck |

| Quality | High-Quality |

| Material | Steel |

| Size | 300mm*300m*350mm |

| Main Prosess | CNC Milling |

| Model Number | OEM |

Custom Process

1. send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Material

Aluminum Sheet

Metal Sheet

Brass Sheet

Copper Sheet

Quality Control

Quality control (QC) in the stamping of gear truck components is crucial to ensure that parts meet the high-performance standards required for heavy-duty applications. Key aspects of QC include precise die design, accurate material selection, and strict monitoring of stamping parameters like pressure, speed, and temperature. QC procedures focus on preventing defects such as dimensional inaccuracies, surface imperfections, and material inconsistencies that could impact gear performance or reliability. In-process inspections, such as dimensional checks, hardness testing, and surface quality assessments, are routinely performed to maintain part integrity. Additionally, post-production testing, including fatigue and stress testing, ensures the stamped gears can withstand the harsh conditions of truck transmissions. By implementing these rigorous QC measures, manufacturers can guarantee the durability, strength, and functionality of each gear part produced.

Processing capability

The processing of stamping gear truck components begins with selecting high-quality raw materials, typically steel or alloy, chosen for their strength and durability. Sheets of material are fed into a stamping press, where precision dies and punches are used to shape the metal into the required part geometry, such as gears, shafts, and housings. The process is carefully controlled to ensure proper alignment, pressure, and speed, minimizing material wastage and optimizing part quality.

Before stamping, die design is critical to achieving tight tolerances and ensuring the part's integrity throughout the process. During stamping, lubrication is applied to reduce friction, prevent wear on dies, and enhance surface quality. Once stamped, parts undergo in-process inspections to check for dimensional accuracy, surface finish, and any signs of defects like cracks or warping.

Additional processes

Post-processing steps may include heat treatment to enhance hardness or stress relief, followed by additional inspections such as non-destructive testing or material hardness testing. Finally, parts are cleaned, deburred, and ready for assembly or packaging. This meticulous approach ensures that stamped gear truck components meet the stringent quality standards necessary for reliable and efficient truck operation.