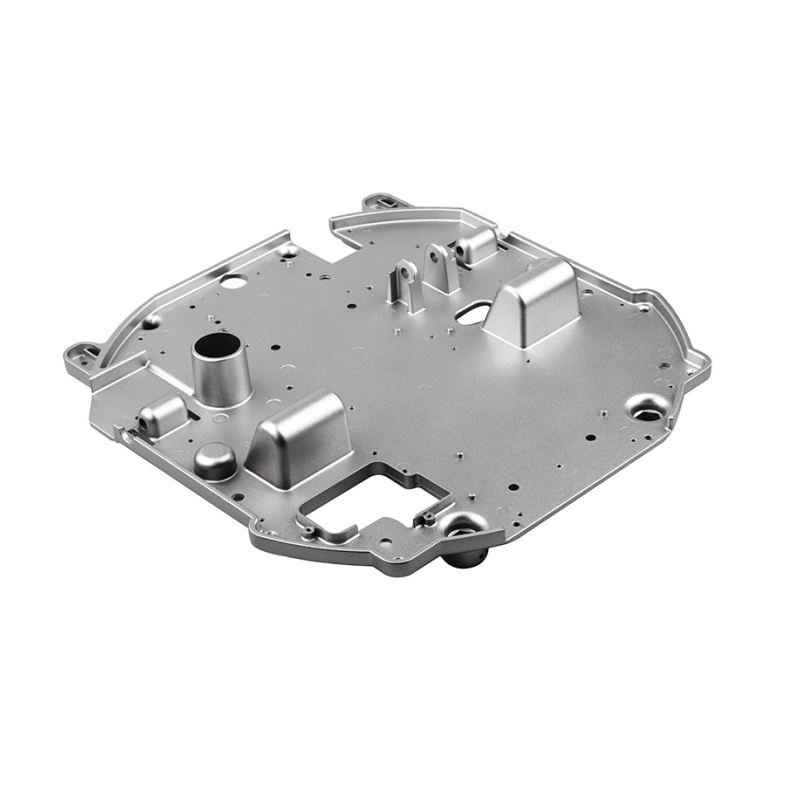

Product Description

Lightweight advantage

Weight is a crucial factor in the design and manufacture of drones. As the main material of precision casting UAV parts die casting, one of its most significant advantages is low density. This low density characteristic makes the overall weight of the UAV greatly reduced. For drones, the lighter weight means less energy needs to be expended to overcome gravity during flight, resulting in a significant increase in flight efficiency. Whether in the take-off, cruise or landing phase, the advantages of lightweight are fully reflected. Moreover, weight reduction can also effectively increase the endurance of the UAV, so that the UAV can cover a wider area in a flight or perform a longer mission, which is highly valuable in applications such as aerial mapping, environmental monitoring, military reconnaissance and other applications.

Product parameters

| specification | argument | specification | argument |

|---|---|---|---|

| Materials | Aluminium alloy: ADC12,ADC10,A360,A380,A356 Magnesium alloy:AZ91D,AM60B Zinc alloy:ZA3#,ZA5#,ZA8# | Quality inspection | Factory inspection :100% inspection of appearance and dimensions |

| Processing technology | Design → Mould-making and die-casting → Draping → drilling and tapping →CNC machining → Polishing → Surface treatment and assembly → Product inspection and packaging → Shipping | Main test set Ready | Three-dimensional detector 2. Automatic image measuring instrument 3. Salt spray testing machine 4. Air tightness detector, dynamic balance detector |

| allowance | ±0.02mm | Characteristics and advantages | Light weight/high strength/good precision/corrosion resistance/good heat dissipation |

| Surface treatment | Powder spraying, oil spraying, sandblasting, polishing, grinding, passivation, chromium plating, zinc plating, nickel plating, electrophoresis, anodizing, etc | Standard | 1.Aluminium alloy:GB/T15114-2009,ISO3522-84,ASTMB85-96,JISH5302:2000,EN1706:1998 2.Magnesium alloy:GB/T25748-2010,ISO/DIS16220-1999,ASTMB93/B93M-98,EN1754-1997 3.Zinc alloy: GB/T13821-2009,ISO301-1981,ASTMB327-98,JISH2021:1999,EN12844:1998 |

| Quality system and testing | ISO9001:2015,SGS test report | Application industry | Intelligent equipment, 3C products, medical devices, auto and motorcycle parts, mechanical parts, power tools, home appliances and furniture parts, LED lighting parts, building materials five. Gold, other metal structures. |

Custom Process

Consult customer service

Confirm specifications

Pay a deposit

Arrange production

Multi-level quality inspection

Pay the balance

Arrange delivery

Confirm receipt of goods

Process Type

Die casting process

High pressure die casting: The use of high pressure to melt aluminum magnesium alloy into the mold cavity quickly, high production efficiency, suitable for complex shapes, large batch parts.

Vacuum die casting: In the process of die casting, the gas in the mold cavity is removed, the porosity is reduced, the casting quality is improved, and it is used for parts with high air tightness requirements.

Precision casting process

Investment casting: Using wax mold to make investment mold, coating refractory materials, roasting and pouring, can manufacture complex parts with high precision and good surface quality.

Disappearing mold casting: foam shape is used, and the shape disappears when pouring, which is suitable for the production of large and shaped UAV accessories.

Semi-solid casting process

The aluminum magnesium alloy in the semi-solid state is die-cast, and the casting quality is good and the precision is high, which is suitable for manufacturing parts with high strength and precision requirements.

Material

Aluminium alloy

Magnesium alloy

Zinc alloy

Quality Control

In strict accordance with ISO9001:2015 and IATF16949 quality standard process operation, the company's quality team is strong, strict control of every detail of production to continuously and stably improve product quality, from incoming, production, to shipment, strict quality control. All finished products are fully inspected and shipped.

Processing capability

Material and process adaptation: Proficient in aluminum-magnesium alloy characteristics, master the die-casting process, can customize the production of high-quality UAV accessories.

Mold making ability: can design and manufacture high-precision molds to meet the complex shape and size requirements of accessories.

Advantages of die casting equipment: Equipped with advanced die casting equipment, accurate parameters can be adjusted to ensure stable and efficient die casting process.

Precision control level: to achieve strict dimensional precision control, error in a very small range, to ensure the assembly performance of parts.

Additional processes

Deburring: The use of professional equipment and technology to remove the burrs on the surface of the accessories to ensure that the surface is smooth and does not affect the assembly.

Machining: According to the design requirements, the necessary mechanical processing of the parts after die casting, such as drilling, milling, etc., to improve the dimensional accuracy.

Heat treatment: Through the appropriate heat treatment process, improve the mechanical properties and internal structure of aluminum magnesium alloy parts.

Surface treatment: According to the need for anodizing, painting and other surface treatment, improve the corrosion resistance and beauty of the accessories.