Product Description

Custom sheet metal fabrication crafts involve the design and production of unique, bespoke items made from sheet metal, tailored to specific needs or artistic preferences. These crafts combine the precision of sheet metal fabrication with the skill of welding, resulting in durable and aesthetically pleasing creations.

Welding custom sheet metal fabrication crafts offer a blend of functionality, artistry, and durability. With versatile materials and processes, these creations cater to a wide range of applications, making them ideal for both practical use and decorative purposes.

Product parameters

| List | Products |

|---|---|

| Product name | Sheet Metal Fabrication Stamping Bending Welding Turnning Parts |

| Materials Avaliable | Stainless Steel Aluminum Metals Copper |

| Tolerance | 0.01-0.05mm |

| Process | Laser Cutting Bending Stamping |

| Surface treatment | Painting\Powder Coating\Plating\Polishing |

| MOQ | Small Orders Accepted |

| Service | OEM\ODM |

| Packing | Standard Packaging |

Custom Process

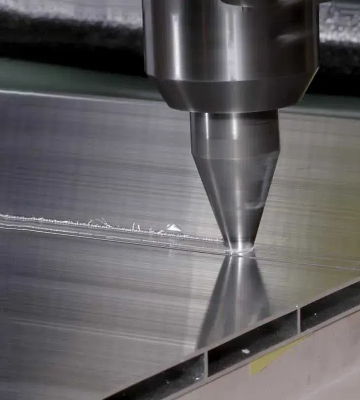

Design and Programming

Machine Setup

Welding Process Execution

Inspection and Finishing

Process Type

Solid State Welding

Newer Welding

Gas Welding

Material

Metal

Aluminum

Copper

Brass

Quality Control

In conclusion, the description for *Welding Custom Sheet Metal Fabrication Crafts* effectively outlines the materials, processes, and applications of these creations, balancing technical details with aesthetic appeal. It is clear, organized, and relevant to its intended audience. However, engagement could be enhanced by incorporating customer-focused benefits or real-world examples. Technical terms are well-used but may need brief clarification for broader accessibility. Overall, it provides a professional and comprehensive overview, with room for slight adjustments to improve readability and relatability. This makes it an excellent foundation for promoting or explaining custom sheet metal crafts.

Processing capability

The processing capability of Welding Custom Sheet Metal Fabrication Crafts reflects a high level of precision, flexibility, and innovation. It encompasses advanced techniques like cutting, bending, and welding, enabling the creation of complex and customized designs. The use of versatile materials such as stainless steel, aluminum, and brass ensures suitability for a wide range of applications, from decorative to industrial.

This capability is further enhanced by state-of-the-art equipment like CNC machines, laser cutters, and press brakes, which guarantee accuracy and efficiency. Various welding methods, including MIG and TIG, provide strong and seamless joins, vital for both structural integrity and aesthetic appeal. Additionally, finishing options such as powder coating, polishing, and engraving allow for tailored designs to meet specific customer preferences.

Additional processes

The capacity for customization ensures flexibility in dimensions, shapes, and designs, making it ideal for bespoke projects. Prototyping and small-batch production also cater to unique needs. Overall, this processing capability highlights a perfect blend of artistry and engineering, delivering durable and visually appealing creations for a variety of purposes.