Product Description

The Robot Joint Motor with modular design, compact joint module, its weight, size, installation mode, appearance lamp compared with the traditional products have done a considerable optimization, mainly used in cooperative robotand and light robot, can meet the miniaturization, lightweight, modular needs to a large extent. it can also be widely used in industrial robots, service robots, industrial automation equipment, lathe equipment and etc.

Product parameters

| Model | Parameters | M5730(B)E17B50L | M5730(B)E17B80L | M5730(B)E17B100L | |

| Overall parameters | Motor rated voltage | 36VDC±10% | 36VDC±10% | 36VDC±10% | |

| Motor rated current | 3.5 A | 3.5 A | 3.5 A | ||

| Output torque after deceleration | 34NM | 35NM | 51NM | ||

| Weight | 1KG | 1KG | 1KG | ||

| Speed range after deceleration | 0~30RPM | 0~18RPM | 0~15RPM | ||

| Reducer parameters | Reduction ratio | 50 | 80 | 100 | |

| Rated torque | 21NM | 29NM | 31NM | ||

| Peak start-stop torque | 44NM | 56NM | 70NM | ||

| Allowable maximum value of average load torque | 34NM | 35NM | 51NM | ||

| Momentary allowable maximum torque | 91NM | 113NM | 143NM | ||

| Backspace | <20 arc seconds | <20 arc seconds | <20 arc seconds | ||

| Design life | 8500H | 8500H | 8500H | ||

| Motor parameters | Torque | 1NM | 1NM | 1NM | |

| Rated speed | 1500RPM | 1500RPM | 1500RPM | ||

| Maximum rotational speed | 2000RPM | 2000RPM | 2000RPM | ||

| Power | 100W | 100W | 100W | ||

| Resistance | 0.86 | 0.86 | 0.86 | ||

| Inductance | 0.8mh | 0.8mh | 0.8mh | ||

| Rotary inertia | 0.69 x 10-4 KG/M2 | 0.69 x 10-4KG/M2 | 0.69 x 10-4KG/M2 | ||

| Feedback signal | Multi-loop absolute encoder (single-loop 15 bit multi-loop 9 bit) | ||||

| Cooling mode | Natural cooling | ||||

| Position Control Mode | Maximum input pulse frequency | 500KHz | |||

| Pulse instruction mode | Pulse + direction, A phase +B phase | ||||

| Electronic gear ratio | Set up ~65535 to 65535 | ||||

| Location sampling frequency | 2KHz | ||||

| Protection function | Over-current alarm | ||||

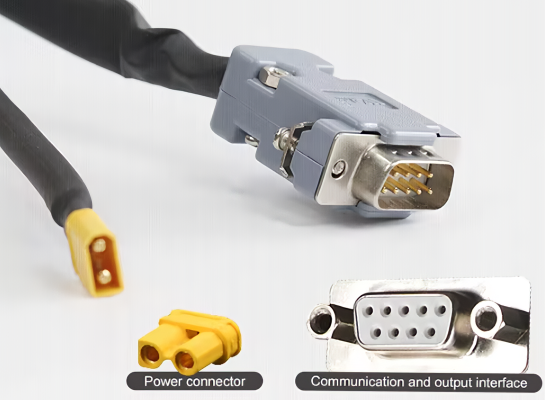

| Communication interface | Canopen (CAN Communication) /Modbus(485 communication) | ||||

| Environment | Ambient temperature | 0~40° | |||

| Maximum permissible temperature of motor | 85° | ||||

| Humidity | 5~95% | ||||

Product Display

- Lsolated CANopen communication

- Built-in isolated power supply

- Low power consumption multi-turn absolute value built-in battery

- Automatic charging

- When the motor is powered, there is a charging circuit inside to charge the battery

- After the motor is not powered, the motor shaft is driven to rotate to wake up the encoder and continue to memorize the position the battery current consumption is only 0.07mA

- Battery power down alarm

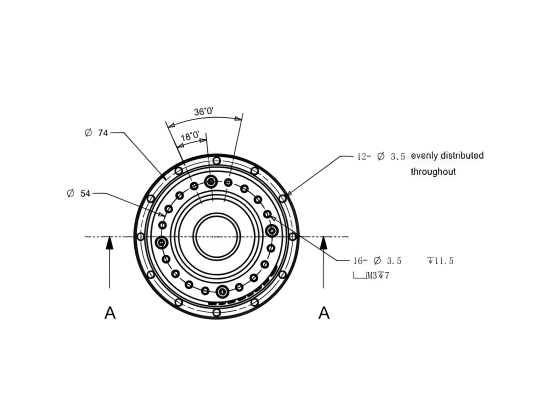

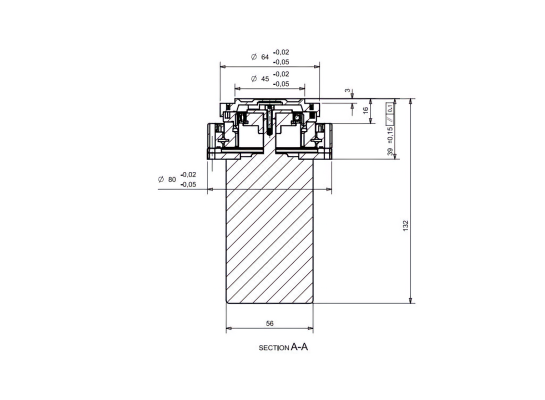

Size & Interface

Application Cases

The joint module is the key component of the robot arm. It can realize the flexible rotation of each joint of the robot arm, so as to accurately complete work such as welding, painting, handling and so on. For example, in the welding work of the automobile manufacturing plant, the joint module of the robot arm can precisely control the position and attitude of the welding head. Through the collaborative work of multiple joint modules, the robot arm can weld on complex automotive body surfaces with high speed and precision, ensuring the stability and consistency of welding quality.

For the material handling robot, the joint module allows the robot arm to extend and grasp freely in three-dimensional space. It can flexibly adjust the joint Angle according to the shape, weight and placement position of the material, accurately grasp the material and place it in the specified position, and improve the automatic production efficiency of the factory.