Product Description

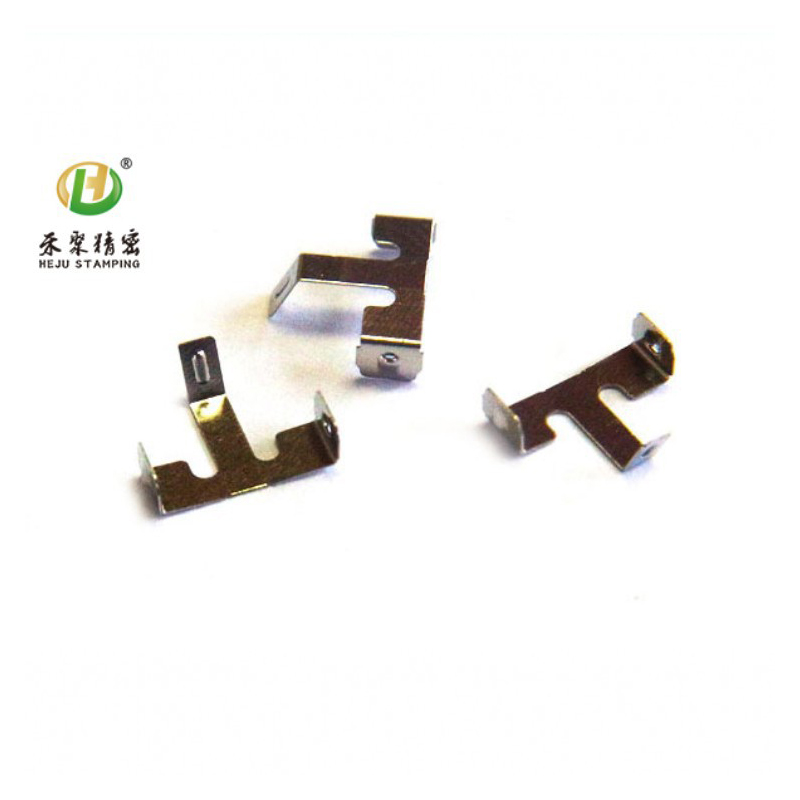

We focus on non-standard precision stamping business and specialize in supplying all kinds of high-quality non-standard precision hardware. These include relay hardware stamping parts, which are exquisitely crafted and can accurately meet the complex structure and performance requirements of relays. At the same time, we also have great advantages in solar stainless steel metal products. These products, with our advanced stamping technology, have excellent performance in precision, strength and durability, providing strong guarantee for the stable operation of solar-related equipment and meeting your needs for high-quality non-standard precision hardware products.

Product parameters

| Parameter name | Parameter value | Parameter name | Parameter value |

|---|---|---|---|

| Brand | Heju | Processable thickness | 0.5-20mm |

| Processable materials | Stainless steel, copper, aluminum | Stamping process | Forming + stretching, bending, flanging |

| Surface treatment | Process coating | Minimum processing size | 0.1 |

| Proofing cycle | 4-7 days | Application area of processing parts | Automotive industry, medical equipment |

| Processing cycle | 1-3 days | Dimensional accuracy | ±0.2mm |

| Maximum processing size | 500 | Product name | Relay Hardware |

| Category (male/female) | Silver corner contacts | Material | k88 T=0.3 |

| Plating specifications | Washing oil | Picth | 10 |

| Rush speed | 300 | Dimensional tolerance | +/-0.02 |

| Flatness | +/-0.02 | Verticality | +/-0.02 |

| Straightness | +/-0.02 | Features | 1. Same as the previous description 2. The material of the shrapnel is required to have high plug-in resistance and low resistance. 3. The stamping production of the shrapnel and the riveting of the silver angle contact must be completed simultaneously in the mold, with a high degree of automation and saving work hours. 4. High production efficiency, the output can reach more than 30,000 pcs per hour. |

| Application | Metal contact shrapnel for relay switches |

Custom Process

1. Demand communication

2. Scheme design

3. Quote and sign contract

4. Mould manufacturing

5. Material procurement

6. Stamping production

7. Post-processing

8. Acceptance and delivery

Process Type

Fine blanking: It is a non-cutting processing technology and a precision stamping method developed on the basis of ordinary stamping technology. It can obtain high-quality stamping parts with higher dimensional accuracy, better surface roughness and better interchangeability than ordinary stamping parts in one stamping stroke. It is mainly used to produce some thin plate parts with complex shapes and high dimensional accuracy in the automotive, electronics, instrumentation and other industries.

Micro stamping: refers to the stamping processing technology with part size in the micron range. The dimensional accuracy of the stamped parts can reach the micron level or even higher. It is mainly used to manufacture tiny parts, such as micro sensors, micro gears, micro springs, etc. It has a wide range of applications in electronics, medical care, aerospace and other fields, such as connectors in microelectronic devices, micro parts in medical devices, etc.

Transfer stamping: It is a multi-station stamping process. It uses molds with multiple stations. The workpiece is transferred from one station to the next station through a robot or other conveying device. Different stamping processes are completed at each station until the stamping of the entire part is finally completed. This process is suitable for the production of stamping parts with complex shapes, large sizes and high precision requirements, such as large covers for automobile bodies.

Material

Magnesium

Copper

Stainless steel

Aluminum

Quality Control

Selected high-quality materials

Ensure product safety and long life from the source

We have established good interactive relationships with well-known domestic and foreign raw material manufacturers (such as Nichimin, Wieland, etc.), mold steel (Hitachi, Datong, etc.) and powder metallurgy manufacturers to ensure the authenticity of the materials used for spring terminals. We can provide quality assurance for the core stamping parts of its electronic components (such as the elastic life of the product's springs, spring surface salt spray test, terminal environmental protection test and other safety indicators, etc.)

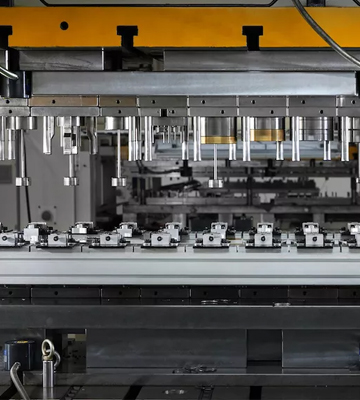

Processing capability

Stamping process

Stamping: Processing iron sheets (metal sheets) into the desired shape on a punch press through a mold.

Forming: Bending, drawing, spinning, shaping, flanging, shrinking, curling, etc. belong to the forming process.

The precision of Heju Precision's equipment can reach ±0.01mm. The tonnage of the equipment ranges from 25T to 160T. All are Japanese or Taiwanese brand punches. All are high-speed gantry punches and C-type punches.

Additional processes

- Electroplating: Through electrolysis, a layer of metal or alloy is deposited on the surface of the stamping part to improve the corrosion resistance, wear resistance, conductivity and other properties of the stamping part, and also improve its appearance. Common electroplating layers include zinc plating, chrome plating, nickel plating, etc. For example, some parts of automobile engines can be effectively prevented from rusting and their service life can be extended after zinc plating.