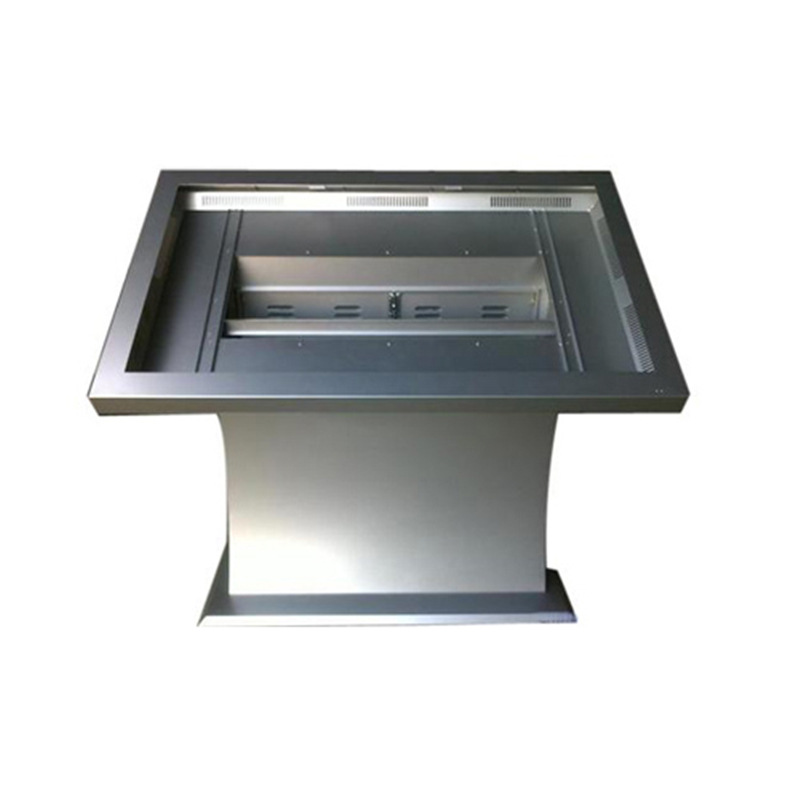

Product Description

Daxin has rich experience in the production of chassis and cabinets. Its surface treatment includes spraying, phosphating, and oxidation. Press-fit rivets can be applied before or after coating. Special welding will not damage the coating of the fingerprint-resistant galvanized sheet, making the interior of the box more beautiful and more corrosion-resistant. In addition, Daxin can also produce special-shaped chassis and cabinets according to your needs. The sheet metal chassis here is for metal sheets generally below 6mm, using comprehensive cold processing processes such as shearing, punching, cutting, compounding, folding, welding, riveting, splicing, and forming, and after cooling, it forms the required chassis.

Product parameters

| Parameter name | Parameter value | Parameter name | Parameter value |

|---|---|---|---|

| Article number | Stainless steel shell | Sheet metal material | Galvanized sheet |

| Sheet material thickness | 1.2 (mm) | Processing size/length*width*height | Customized as required (mm) |

| Molding parts | Chassis | Blanking way | Laser cutting |

| Tolerance | 0.1 | Processing procedure | Welding, notching, cutting, stamping, filleting, forming, punching, bending, embedding, flanging, flanging, ribs |

| Surface treatment | Baking paint | Surface roughness | 0.05 |

| Proofing cycle | 1-3 days | Processing cycle | 1-3 days |

| Application area | Bridges, household goods, public facilities, communications, car and ship transportation, electricity, office supplies, industrial equipment, construction |

Custom Process

1. Put forward a demand

2. Initial communication

3. Solution design and quotation

4. Confirmation of the plan

5. Contract Conclusion

6. Payment of advance

7. Customized production and supervision

8. Acceptance and final payment

Material

Galvanized sheet

Copper

Carbon Steel

Stainless steel

Quality Control

Strong sheet metal shell processing capabilities

Modern environmentally friendly factory buildings, reasonable production layout. The company has advanced laser cutting equipment and CNC equipment at home and abroad, and always insists on focusing on the processing and production of sheet metal chassis shells. With exquisite craftsmanship, the company has always been at the forefront of the industry in sheet metal processing design and production. The company's production team consists of experienced technicians and skilled operators in sheet metal processing. We insist on using high-tech equipment to improve production efficiency and strive to provide users with complete solutions.

Processing capability

- Material pretreatment: We have professional material pretreatment equipment and processes, including cutting, forming, surface treatment, etc. We can accurately cut and form materials according to welding requirements to ensure the dimensional accuracy and shape accuracy of weldments; at the same time, we can effectively remove impurities such as oil, oxide scale, etc. on the surface of materials to improve welding quality.

Additional processes

Use grinding tools, wire brushes, etc. to remove impurities such as slag and spatter on the weld surface to make the weld surface smooth and neat. Weld cleaning can not only improve the appearance quality of the product, but also facilitate subsequent quality inspection and surface treatment processes.

In order to meet the surface quality requirements of the product or the assembly requirements with other parts, the weld is ground and polished to make the transition between the weld and the parent material surface smooth, improving the overall appearance and finish of the product.