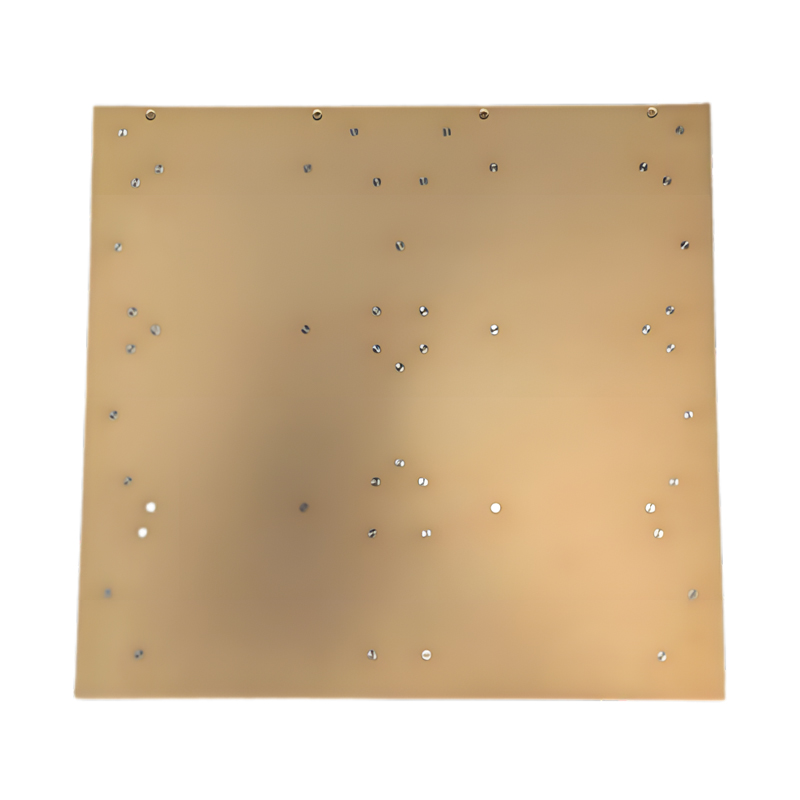

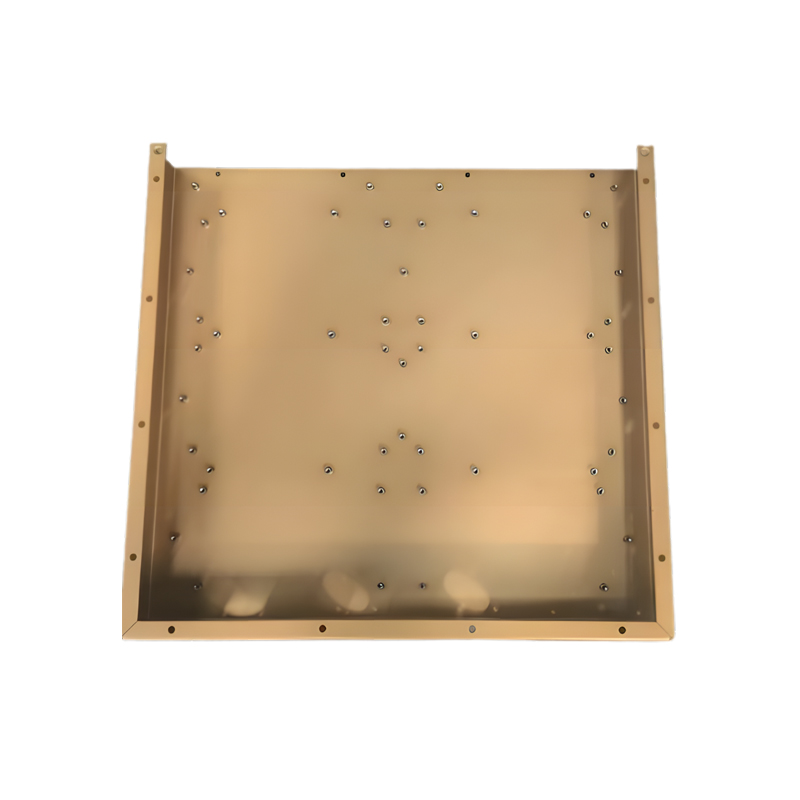

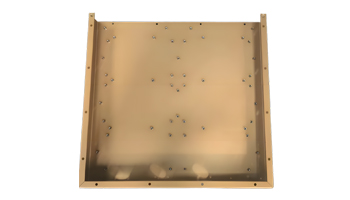

Product Description

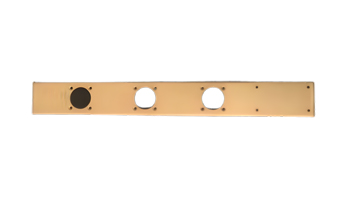

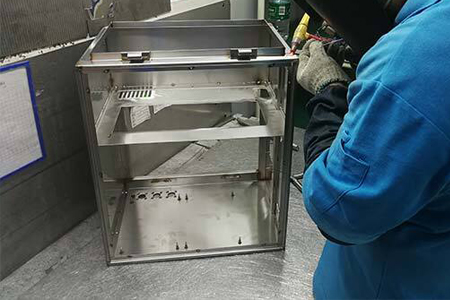

We are a professional non-standard precision sheet metal welding manufacturer, focusing on the production, manufacturing and processing of U boxes. We have advanced welding technology and precision processing equipment, starting from the strict screening of raw materials, to ensure that every link meets high standards. Our technical team is experienced and can accurately control the dimensional accuracy and welding quality of the U box, making it stable in structure and exquisite in appearance. Whether it is complex design requirements or special use environments, we can customize and produce high-quality U boxes for customers to meet the stringent needs of various industries for non-standard precision sheet metal products.

Product parameters

| Parameter name | Parameter value | Parameter name | Parameter value |

|---|---|---|---|

| Surface treatment | Baking paint | Sheet metal material | Aluminum plate |

| Sheet thickness | 1.5 (mm) | Processing size/length*width*height | As required (mm) |

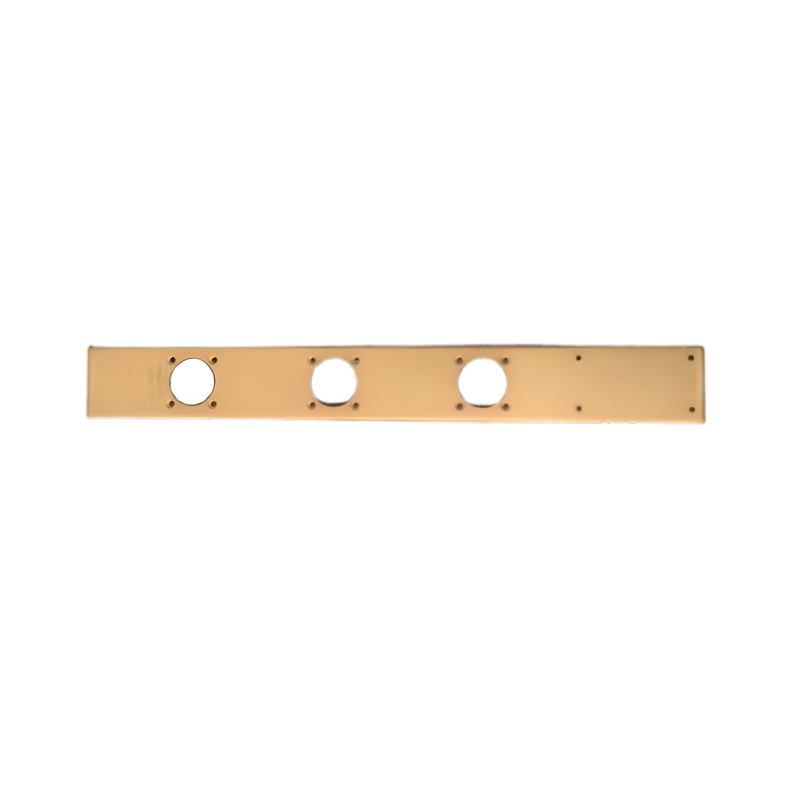

| Molding parts | Chassis | Cutting method | Laser cutting |

| Tolerance | 0.1 | Processing procedure | Welding, flanging, punching, cutting, filleting, unfolding, stamping, forming, bending, embedded flanging, punching, ribbing |

| Processing cycle | 1-3 days | Surface roughness | 0.05 |

| Proofing cycle | 1-3 days | Annual remaining processing capacity | 10000 |

| Annual maximum processing capacity | 100000 | Application area | Bridges, household goods, public facilities, communications, car and ship transportation, electricity, office supplies, industrial equipment, construction |

Custom Process

1. Put forward a demand

2. Initial communication

3. Solution design and quotation

4. Confirmation of the plan

5. Contract Conclusion

6. Payment of advance

7. Customized production and supervision

8. Acceptance and final payment

Material

Aluminum Plate

Stainless steel

Galvanized sheet

Carbon Steel

Quality Control

Cangzhou Daxin Electric Co., Ltd. is the company's "chassis cabinet sheet metal processing base" located in Qing County, Hebei Province. It is a large sheet metal processing factory in North China. It has been focusing on the sheet metal processing industry for more than ten years and is a comprehensive supplier of sheet metal overall solutions. The company is engaged in laser cutting and processing of supplied materials and has its own sheet metal processing production line, spraying line, assembly line and engineering team.We truly provide one-stop service from design customization, processing and production to finished product assembly and after-sales tracking.

Processing capability

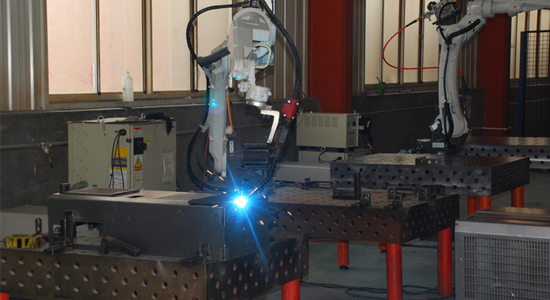

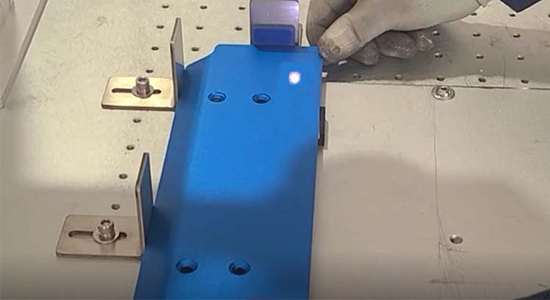

The manufacturer is equipped with advanced welding robot systems. These robots have high-precision positioning and motion control capabilities and can accurately perform welding tasks.

Whether it is a complex sheet metal structure or a product with extremely high welding quality requirements, robot welding can ensure the uniformity, strength and aesthetics of the weld. Moreover, through programming, welding parameters and paths can be flexibly adjusted to stabilize and improve the appearance and internal quality of welded parts; improve labor productivity; improve the labor intensity of workers, and work in harmful environments; reduce the requirements for workers' operating skills; shorten the cycle of product modification and replacement, and reduce the corresponding equipment investment.

Additional processes

- Drilling: According to the design requirements, various specifications of holes are drilled on the sheet metal parts for installing bolts, nuts, rivets and other connectors, or as holes for ventilation, heat dissipation, observation and other purposes. The drilling precision is high, and professional equipment such as drilling machines are required, equipped with suitable drill bits and fixtures to ensure the position accuracy and size accuracy of the holes.

- Component assembly: Assemble the processed and treated sheet metal components according to the design requirements to form a complete U box product. Various connectors, such as bolts, nuts, rivets, spot welding, etc., are required during the assembly process to ensure that the connection between components is firm and reliable. At the same time, attention should be paid to the accuracy and order of assembly to ensure the overall quality and performance of the product.