Product Description

High quality materials

The internal wiring harness of the cooking robot is carefully made of high quality materials. Wire selection of high-purity copper to ensure excellent electrical conductivity, ensure the efficient transmission of power and signals. Insulation materials include polyvinyl chloride (PVC) and cross-linked polyethylene (XLPE), which have excellent insulation properties and corrosion resistance, can effectively prevent short circuits, and protect the harness in the complex internal environment of the robot safe operation. The metal contact of the connector is a high quality copper alloy, and the plastic housing is strong and well insulated. The protective sleeve includes bellows and braided tubes, the former is flexible and flexible, the latter is anti-tensile and has electromagnetic shielding function, and the wire harness fixing material cable ties and fixing clips are reliable and easy to use.

Product parameters

| specification | argument | specification | argument |

|---|---|---|---|

| Product name | Stir-frying robot internal wiring harness | colour | Red, black, yellow |

| Connector specification | Aamss-XT60+XT90+PHD2.0 | Line length | 400mm customizable |

| Wire rod | UL2464+UL1007 20AWG | Feature | Resistant to bending and rocking |

| quantity | 1000PCS, please consult customer service for special parts | All materials match | UL、ROHS、REACH+NP |

| Main component | UL4478 Ultra-soft multi-core cable, UL20276 high flexible shielded cable | sample | Samples of conventional products can be provided free of charge, please contact customer service for details |

Custom Process

Consult customer service

Confirm demand

Offer negotiation

Order and pay

We make plates and designs

You confirm the plan

confirm

Put into production

Confirm receipt of goods

Process Type

Wire processing technology

Peeling: Precisely control the length and depth to remove the insulation layer at both ends of the wire.

Connector assembly process

Select a matching connector, paying attention to the insertion direction and depth, and the degree of fastening of the fastener.

Casing installation technology

Install suitable sized protective or electromagnetic shielding bushings to ensure protection and without affecting harness performance.

Material

Wire material

Insulating material

Protective casing material

Wire harness fixing material

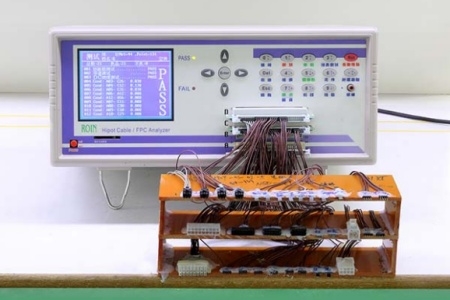

Quality Control

The internal wiring harness quality control of the cooking robot covers raw material inspection, including quality control of wires, insulation materials, connectors, etc. In the production of wire processing, connector assembly, sleeve installation, marking links strictly control; The finished product should be tested for electrical properties, mechanical properties and environmental adaptability to ensure reliable quality of the wiring harness.

Processing capability

Wire processing capability

With advanced equipment and skilled personnel, high precision peeling (error ±0.5mm), precise cutting (tolerance ±1mm), high quality tin welding (good solder joint, temperature and time control).

Connector assembly capability

Can be adapted to different specifications of connectors and wire assembly, insertion depth deviation within ±0.3mm, and assembly efficiency, high quality.

Casing installation capability

Master a variety of casing installation technologies, covering more than 95%, and can be customized to enhance durability.

Additional processes

Cleaning process: After the processing is completed, clean equipment such as electrostatic dust gun and cleaning brush are used to remove debris and dust on the surface of the wiring harness to avoid short circuit or poor contact caused by impurities entering the connector, reducing the risk of running the cooking robot.

Protective coating process: Depending on the location and environment of the wiring harness in the robot, select moisture-proof paint, anti-corrosion paint and other coatings, and spray or dip to form a uniform coating of 20-50 μm thick to enhance protective performance, extend service life and do not affect the flexibility and installation.