Product Description

Various specifications

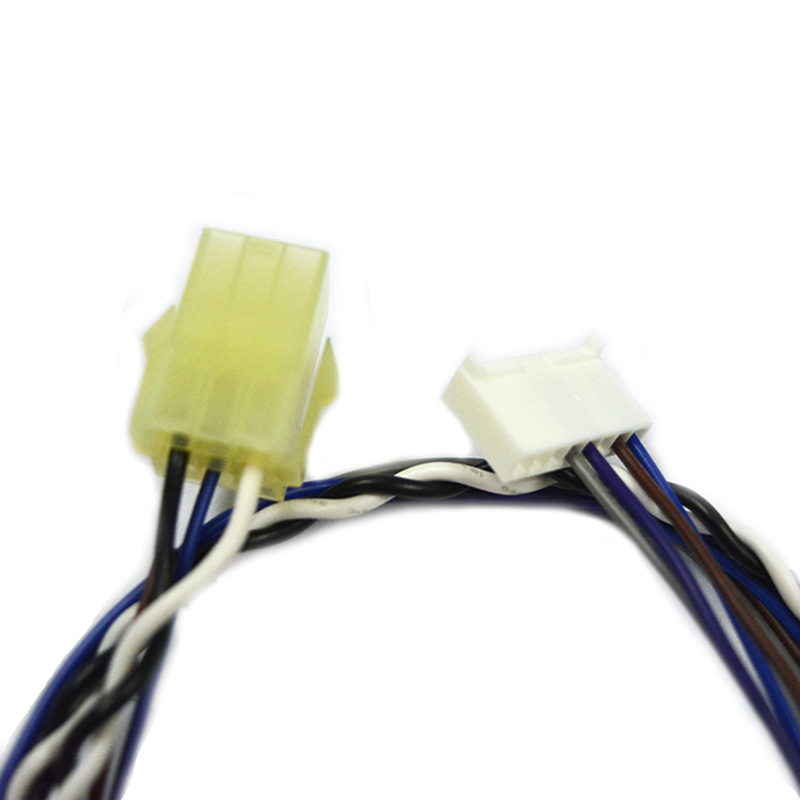

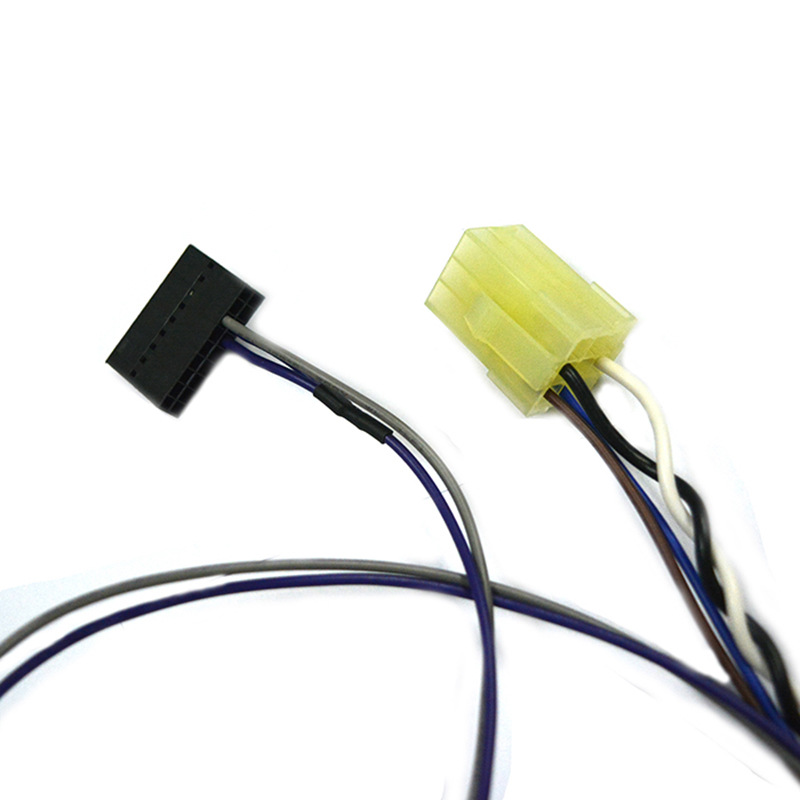

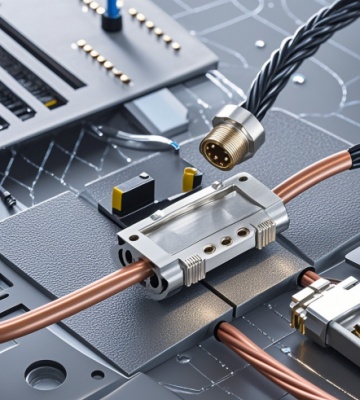

There are various types of interfaces, including wire-to-board, board-to-board, and I/O connectors. There are a variety of current and voltage adaptation specifications to meet the needs of different components. The number of pins and spacing options are wide, adapted to various circuit and space requirements.

Good quality

Wire with high purity copper material, good conductivity. Good insulation material performance, wear resistance, corrosion resistance. Connector manufacturing precision is high, the performance of contact parts is good, and the cable processing technology is strict.

Strong connectivity

Suitable insertion and withdrawal force, reliable locking structure, and stable connection under vibration impact. Some products have shielding design to prevent electromagnetic interference and ensure signal integrity.

Flexible design

The cable is flexible and convenient for complex wiring in the robot. The connector is easy to install and disassemble, which is conducive to production, maintenance and cost saving.

Product parameters

| specification | argument | specification | argument |

|---|---|---|---|

| Product name | MOLEX robot connection cable | colour | Red, black, yellow |

| Connector specification | MOLEX3.96 | Line length | 300mm customizable |

| Wire rod | UL1007 26AWG | Feature | Resistant to bending and rocking |

| quantity | 1000PCS, please consult customer service for special parts | All materials match | UL, ROHS, REACH+NP |

| Main component | UL4478 Ultra-soft multi-core cable, UL20276 high flexible shielded cable | custom | Provide OEM processing customization |

Custom Process

Demand communication

Firm offer

Proof making

Sign an order

Pay for goods

Mass production

Quality inspection delivery

After-sales service

Process Type

Stamping process:For the production of connector metal contact parts, high precision, can control the size and shape, form a complex structure, to ensure the connection performance.

Stranding process: stranding a number of copper wires to make wire, suitable for high current or need flexibility, control the stranding parameters, improve current transmission efficiency and bending resistance.

Shielding process: In order to resist electromagnetic interference, the wire is outfitted with a metal shielding layer to ensure its integrity and tightness, do a good job of grounding treatment, and the connector is also shielded.

Material

Shielding material

Connector metal material

Insulating material

Wire material

Quality Control

Technical team: 20 senior product engineers to provide customers with perfect design solutions.

Production team: 30 experienced production management, 320 skilled first-line production personnel to ensure your order delivery time.

Quality team: 31 excellent quality specialists, for your product quality escort.

Processing capability

A variety of processing capabilities

Stranding parameter control

For wire production, the stranding process can twist multiple copper wires (such as 7 strands, 19 strands, etc.) according to the specific direction and pitch. By accurately controlling parameters such as stranding speed and tension, the wire structure is tight and uniform, and the bending resistance and current transmission efficiency are improved.

Welding quality control

In the connection between the wire and the contact, whether it is tin welding (temperature 250-350 ℃, time 2-5 seconds) or laser welding, it can ensure the quality of the solder joint, avoid virtual welding, welding leakage, and ensure reliable electrical connection.

Additional processes

Surface treatment process

Metal-contact parts are gold-plated and silver-plated, the thickness is controlled within a certain range, and the electrical conductivity and oxidation resistance are enhanced. The plastic shell is sprayed, frosted and other treatments to improve aesthetics, wear resistance and corrosion resistance.

Marking procedure

By means of color coding, labels, printed characters, etc., it is clear that the function, number and connection position of each wire harness are convenient for installation and maintenance identification.