Product Description

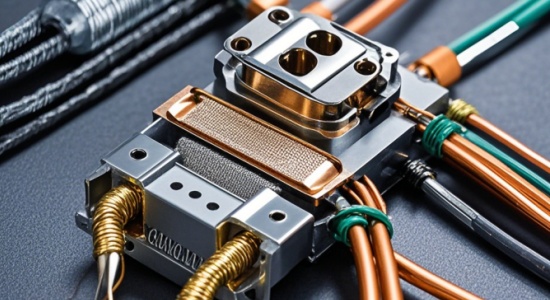

Interface specifications: SM2.5 and MX3.0 interfaces are used to adapt the corresponding industrial device ports to ensure accurate connection.

Wire performance: wire core quality, good conductivity, reliable insulation layer, stable transmission signal and current.

Application scenario: Designed for the internal connection of industrial equipment to meet the requirements of complex industrial environments and ensure efficient communication and collaborative operation between devices.

Product parameters

| specification | argument | specification | argument |

|---|---|---|---|

| Product name | SM2.5/MX3.0 Internal cables for industrial equipment | colour | Red, black, yellow |

| Connector specification | SM2.5 | Line length | 300mm customizable |

| Wire rod | UL1007 26AWG | Feature | Resistant to bending and rocking |

| quantity | 1000PCS, please consult customer service for special parts | All materials match | UL、ROHS、REACH+NP |

| Main component | UL4478 Ultra-soft multi-core cable, UL20276 high flexible shielded cable | Core material | Tinned copper wire |

Custom Process

Consult customer service

Confirm demand

Offer negotiation

Order and pay

We make plates and designs

You confirm the plan

confirm

Put into production

Confirm receipt of goods

Process Type

Wire processing: The selection of high-quality copper drawn wire core, to ensure high purity and suitable diameter, and then wrap temperature resistant, high insulation plastic insulation layer.

Terminal processing: stamping and forming the terminal, the main body is made of high-strength brass, and the surface is plated with tin or nickel to ensure dimensional accuracy and good contact performance.

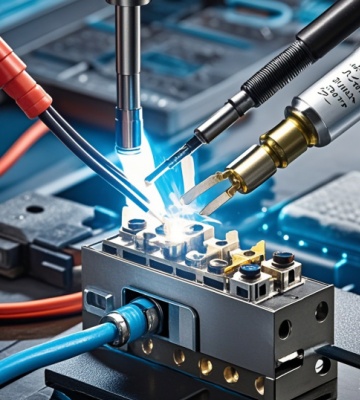

Welding: Weld the wire and terminal with suitable high-quality solder, and cooperate with stable flux to ensure firm and no virtual welding.

Material

Wire harness fixing material

Terminal material

Wire material

Additional material

Quality Control

Technical team: 20 senior product engineers to provide customers with perfect design solutions.

Production team: 30 experienced production management, 320 skilled first-line production personnel to ensure your order delivery time.

Quality team: 31 excellent quality specialists, for your product quality escort.

Processing capability

Precision manufacturing

Using high-precision equipment, the wire stripping, cutting length accuracy up to millimeter, stranding wire pitch and other parameters of the error is very small, to ensure the size of the wire harness accurate.

Efficient assembly

Automatic insertion of wires to connectors, fast and 99% accuracy, welding process to ensure solder joint quality, high assembly efficiency.

Reliable detection

With comprehensive testing capabilities, can quickly and accurately test wiring harness conduction, insulation, voltage resistance and other properties to ensure product quality.

Additional processes

Surface treatment

Gold plating and silver plating on metal contact parts, controlling thickness to enhance conductivity and oxidation resistance; The plastic shell is sprayed and frosted to improve the appearance, wear resistance and corrosion resistance.

Mask processing

Wrap the wire with copper foil or braided metal mesh as a shielding layer to ensure coverage of more than 90% and good grounding; The connector is shielded to reduce electromagnetic interference.