Product Description

The explosion-proof valve uses Japanese light metal high-performance, high-formability aluminum MFX2-0; the elongation can reach 40%, and the mechanical processing performance is good, which meets the requirements of heat resistance, impact resistance, and aging resistance of power battery explosion-proof valves (sheets). The explosion-proof value can be adjusted inside the mold to meet the different product requirements of customers, save mold costs, and shorten sample delivery time.

Product parameters

| Name | Parameter | Name | parameters |

|---|---|---|---|

| Name | Battery explosion-proof disc | Process | Stamping and forming |

| Specifications and dimensions | Can be customized according to drawings | Material | Metallic |

| Features | High temperature resistance and corrosion resistance | Application | Battery explosion protection valve |

| Explosion value | 0.65-2.8MPA<br> | Burst value accuracy | 0.05MPA<br> |

Technological Innovation

The explosion-proof disc, also known as the explosion-proof valve of new energy batteries, is a thin metal sheet that is resistant to strong ultrasonic shocks and can effectively prevent battery explosions. When the internal pressure of the battery rises abnormally, such as when the battery is overcharged, short-circuited, or a violent chemical reaction occurs inside to produce a large amount of gas, the explosion-proof disc can rupture in time to release the pressure inside the battery. This can effectively prevent the battery shell from rupturing or even exploding, and avoid the leakage of harmful substances such as the electrolyte inside the battery, thereby ensuring the personal safety of users and the safety of equipment. For example, in the lithium batteries of some portable electronic devices such as mobile phones and laptops, explosion-proof discs play a key safety protection role.

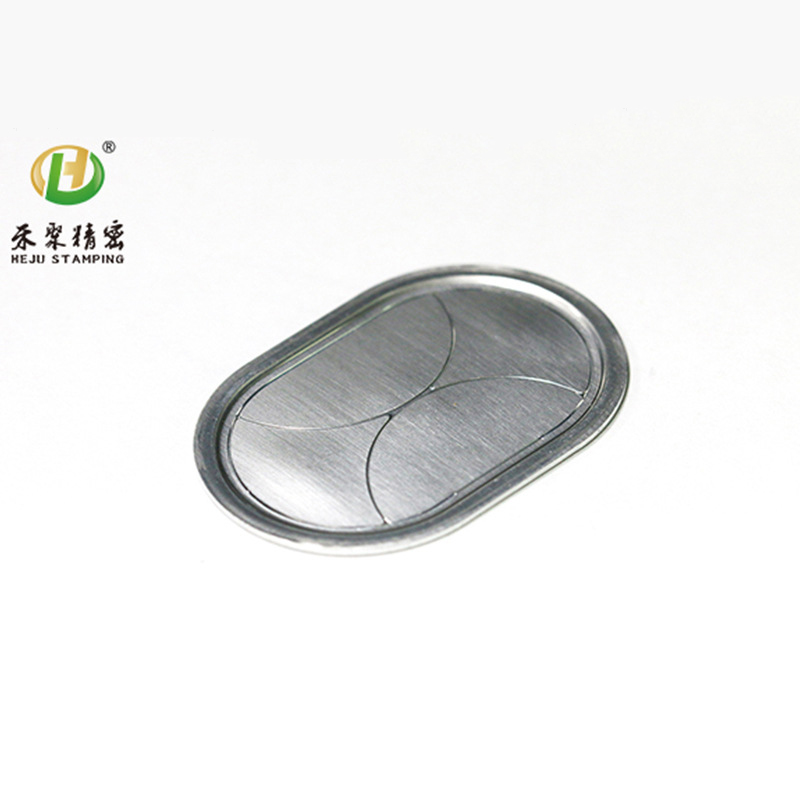

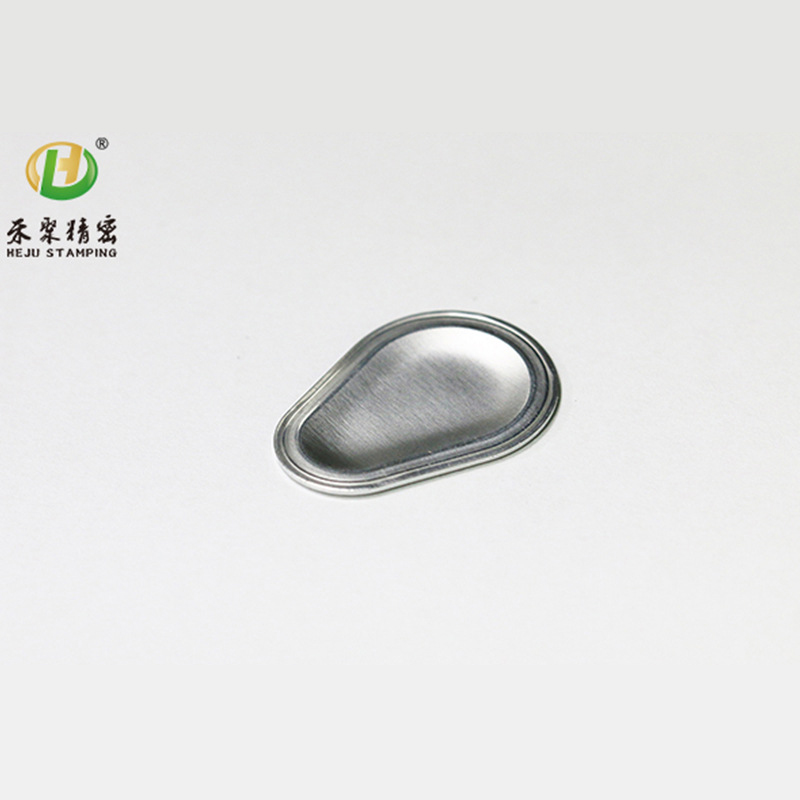

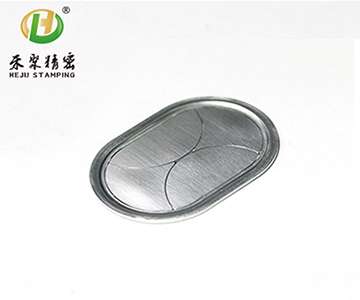

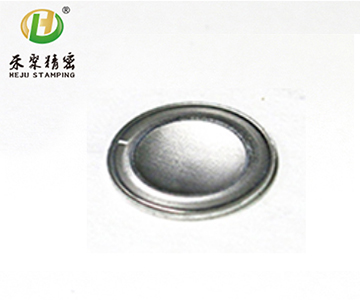

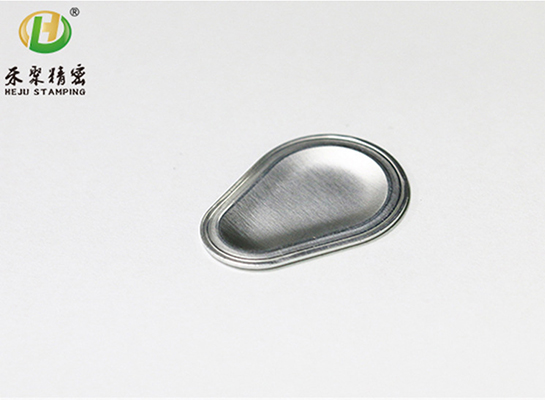

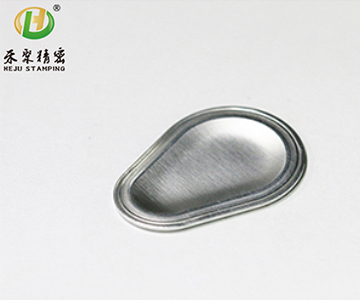

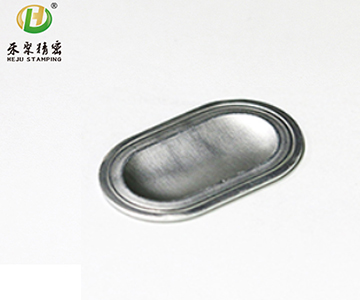

Product Display

Heju Precision has six major production technologies: precision spring forming technology, precision punching technology, stretching technology, precision cold forging technology, fine stamping technology, and X/Y axis two-way composite stamping technology. It customizes small hardware for energy vehicles, electronic digital, smart appliances and other industries, mainly processing explosion-proof plates, battery flip plates, power battery explosion-proof valves and other small hardware.

Dongguan Heju Precision Electronic Technology Co., Ltd. has rich experience in designing and processing molds for battery explosion-proof plates, power battery explosion-proof valves, cover plates, new energy battery explosion-proof plates and other parts. It uses precision high-speed stamping equipment imported from Japan to ensure the stability of explosion-proof air pressure values, stable production, timely delivery, and meet customer mass production requirements.

Quality Control

- Material testing

Each batch of incoming materials can provide a spectrum analyzer test report, which shows whether it is branded material or miscellaneous smelting material. Ensure the authenticity of the shrapnel materials.

- Precision testing

Forming tolerance and bending ∠R tolerance are measured using imported brand instruments. For example: 2D: ±0.001mm, 3D

- Performance testing

Using a Japanese stiffness testing machine, the shrapnel can be tested for fatigue resistance, yield testing, and stiffness testing.

- Surface process test

Use a film thickness gauge to measure whether the thickness of the coating on the surface of the shrapnel meets the standard. Use a salt spray tester to test the corrosion resistance of the electroplated shrapnel.

Application Cases

Dongguan Heju Precision was established in 2008 and focuses on the production of explosion-proof valves for power batteries. At present, it has cooperated with well-known domestic companies such as Baisi Li and Xinwangda for many years. The production of explosion-proof valves has formed standardized operations and large-scale production to meet customer quality requirements. It can quickly cooperate with customer operation processes in a short time, reduce communication costs, and improve operation efficiency.

Cooperative partner