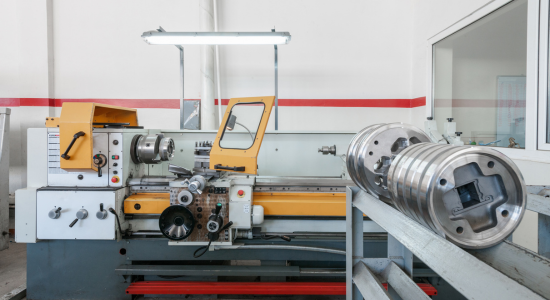

Product Description

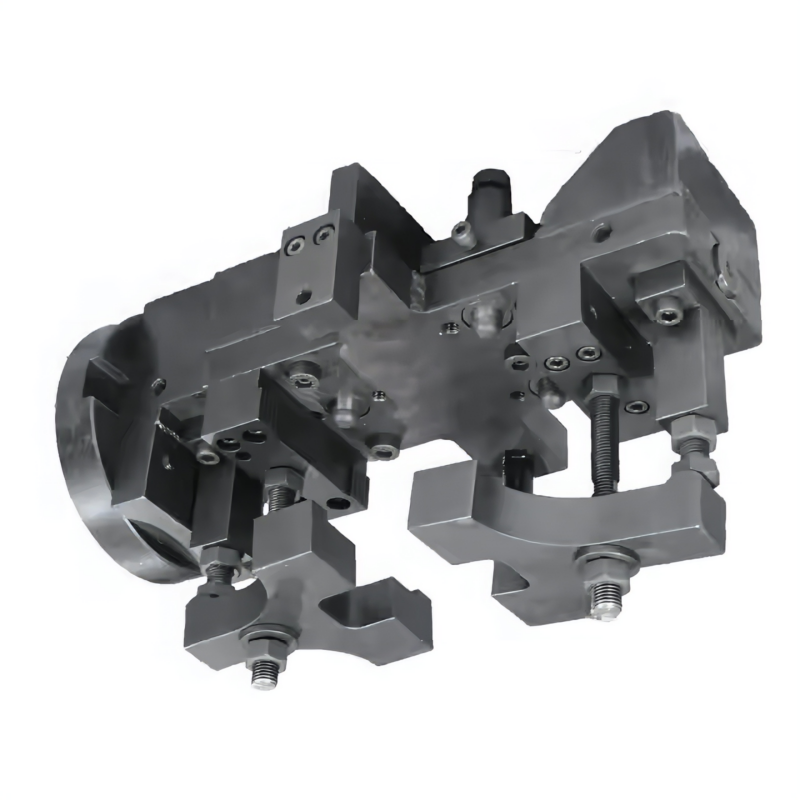

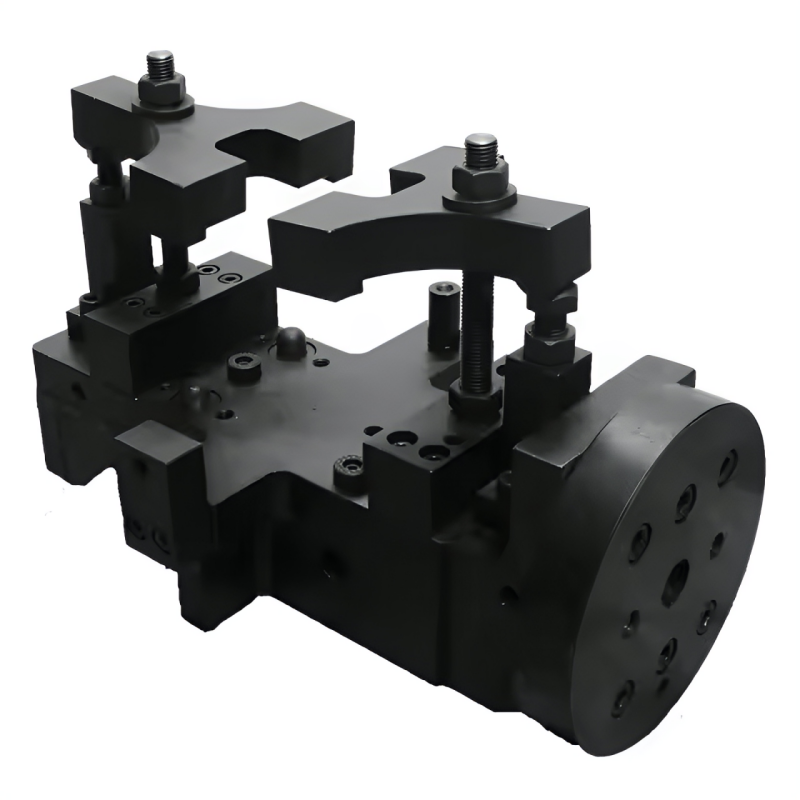

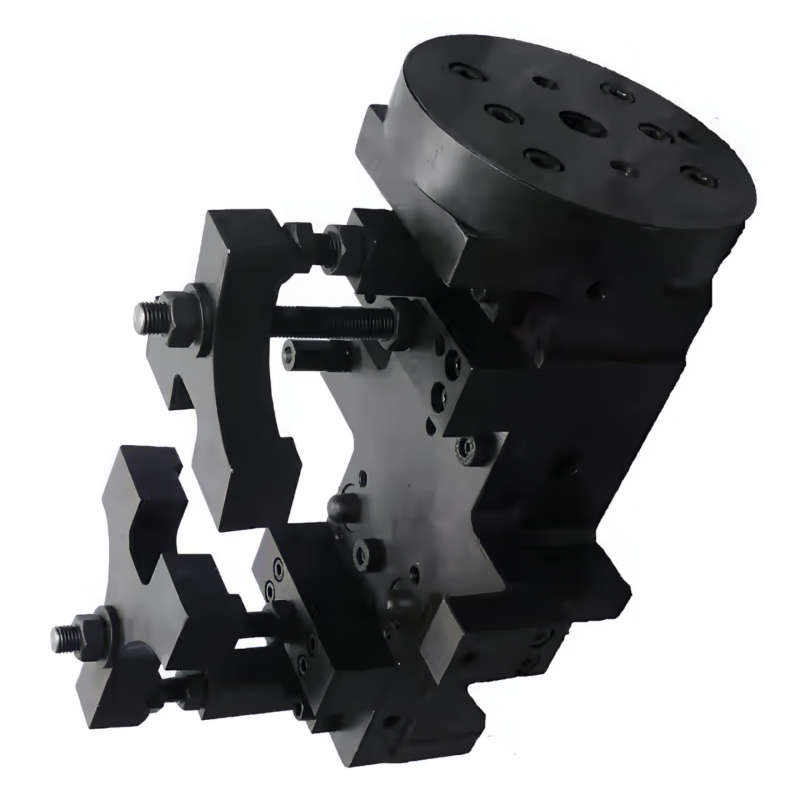

Our customized fixtures for lathe, milling, and CNC processes ensure precise workpiece positioning, stability, and accuracy. Designed to handle high forces and vibrations, they reduce part movement and improve machining efficiency. Tailored to your specifications, these durable fixtures enhance production quality and consistency while maintaining tight tolerances.

Product parameters

| Attribute | Details |

|---|---|

| Type | DRILLING, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Micro Machining | Not Micro Machining |

| Process | CNC Machining |

| Dimension | Customize |

| Tolerance | Customer's Drawing Request |

| Service | Design |

| Application | Automobile |

| Material | Aluminum Alloy |

| Packing | Custom Packaging |

| Our Service | Development Services |

| Materials Available | Multiple Materials |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Heavy Machinery Components

Products:

Such as crane structures, grinding machine gears, or mining machinery parts

Reasons for Using this Fixture

Aerospace Components

Products:

Such as jet engine blades, aircraft fuselage, or electrical wiring systems in aircraft

Reasons for Using this Fixture

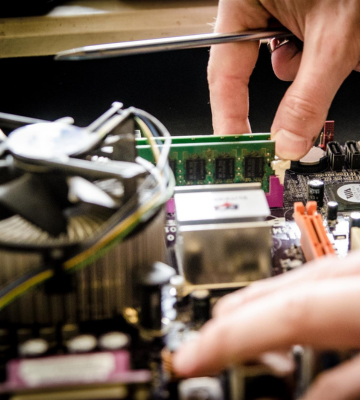

Electronic Components

Products: Printed Circuit Boards (PCBs) or capacitors

Reasons for using this fixture

Material

Aluminum Alloy

Stainless Steel

Quality Control

Quality control for fixture systems in lathe, milling, and CNC processes ensures precision, stability, and durability. Each fixture is carefully inspected for dimensional accuracy, material integrity, and surface finish. Rigorous testing is performed to verify proper alignment and clamping force, ensuring the workpiece remains securely in place during machining. Additionally, the fixtures are checked for performance under operational conditions to guarantee reliability, repeatability, and long-term functionality, meeting customer specifications and industry standards.

Processing capability

The processing capability of fixtures for lathe, milling, and CNC processes includes precise design and manufacturing to ensure accurate workpiece positioning and stability. These fixtures are engineered to handle high machining forces, offering strong clamping and alignment for complex parts. With advanced machining techniques, they are customizable to meet specific tolerances and application requirements, ensuring efficient and reliable performance in various production environments.

Additional processes

Additional processes for fixtures in lathe, milling, and CNC operations include surface treatments such as anodizing or coating for enhanced durability and corrosion resistance. Fixtures may also undergo assembly and precision testing to ensure proper fit, alignment, and functionality. These processes help optimize fixture performance, ensuring reliable, long-lasting use in demanding machining environments.