Product Description

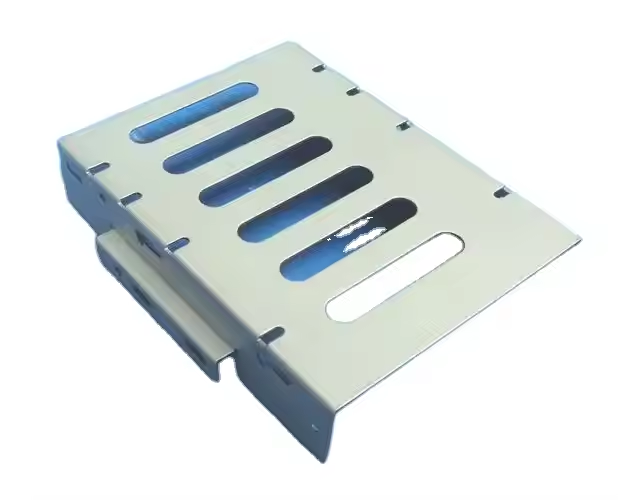

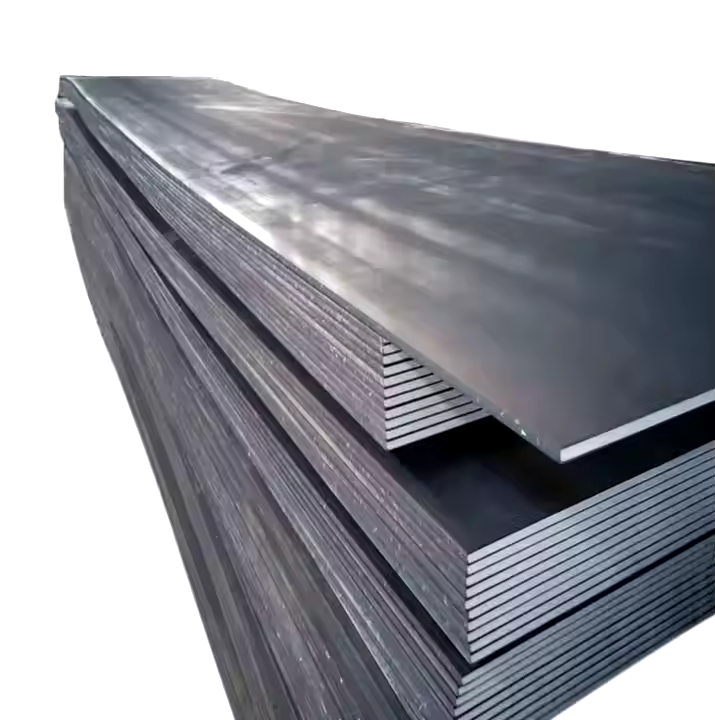

A sheet metal enclosure is a protective housing or casing made from thin sheets of metal, typically used to encase electronic components, machinery, or electrical devices. These enclosures are designed to shield sensitive equipment from physical damage, dust, moisture, and electromagnetic interference. Common materials used include steel, aluminum, and stainless steel, offering durability, strength, and corrosion resistance. Sheet metal enclosures are widely used in industries like electronics, telecommunications, automotive, and industrial equipment for both indoor and outdoor applications.

Product parameters

| List | Details |

|---|---|

| Brand Name | Welding & Cutting part |

| Color | Customized Colors |

| OEM/ODM | OEM ODM CNC Milling Turning Machining Service |

| MOQ | Small Orders Accepted |

| Logo | Accept Custom Logo |

| Application | Industrial Equipment |

| Service | Customized OEM CNC Machining |

| Equipment | CNC Machining Centres |

Custom Process

Design and Programming

Machine Setup

Welding Process Execution

Inspection and Finishing

Process Type

Solid State Welding

Newer Welding

Gas Welding

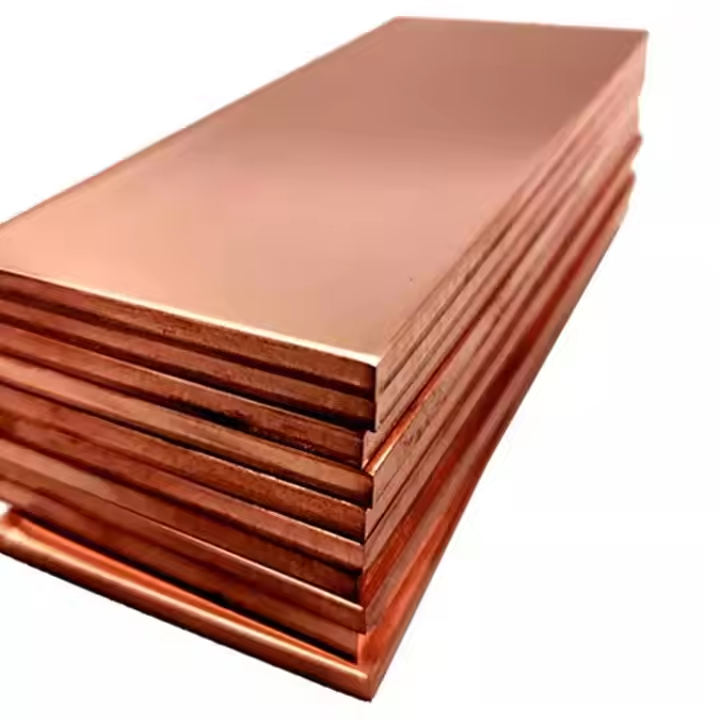

Material

Metal

Aluminum

Copper

Brass

Quality Control

Quality Control (QC) of Sheet Metal Enclosures ensures that the final product meets required standards of durability, functionality, and safety. QC involves checking for dimensional accuracy, verifying proper fit and alignment, and ensuring there are no defects like sharp edges, dents, or cracks. Surface finish is also inspected to ensure it meets specifications for aesthetics and protection. Material quality, such as corrosion resistance, is tested to ensure longevity. Additionally, the enclosure’s functionality is tested to confirm it can adequately protect the components inside. Automated and manual inspection methods are often employed for comprehensive quality assurance.

Processing capability

The processing capability of sheet metal enclosures refers to the ability of manufacturing systems and techniques to produce high-quality, precise enclosures from metal sheets. This capability includes various factors that influence the design, production, and functionality of the enclosures:

Material Handling: Sheet metal enclosures can be made from a variety of metals, including steel, aluminum, and stainless steel, each offering unique properties like strength, corrosion resistance, and lightweight characteristics.

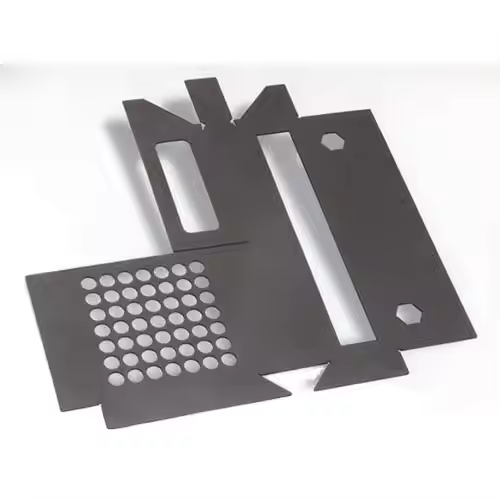

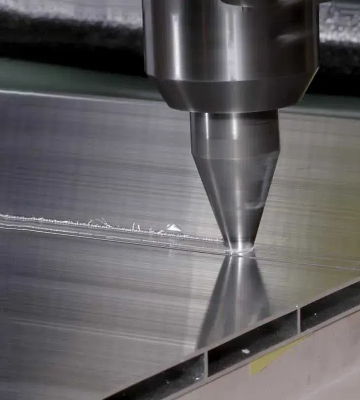

Cutting and Shaping: Technologies like laser cutting, water jet cutting, and punching are used to shape and cut the metal sheets into the desired forms with high precision.

Forming and Bending: Processes like press braking and stamping allow for the bending and shaping of sheet metal to form the enclosure’s walls, flanges, and features like vents or mounting points.

Welding and Assembly: Welding techniques such as TIG or MIG welding are employed to join metal parts, ensuring the enclosure is robust and secure.

Additional processes

Surface Treatment: Surface finishing processes such as powder coating, anodizing, or galvanizing are applied to enhance corrosion resistance, aesthetics, and durability.

Precision and Tolerance: High-precision CNC equipment ensures that enclosures meet strict dimensional tolerances, necessary for fitting electronic components and ensuring proper assembly.

Customization: The ability to create custom features, such as holes for cable management, ventilation, or mounting, increases the versatility of sheet metal enclosures for various applications.

Automation: The use of automated systems enhances speed and consistency, ensuring cost-effective production, especially for high-volume orders.

In summary, the processing capability of sheet metal enclosures is defined by the combination of material selection, precision manufacturing techniques, surface treatments, and customization options that allow for the production of high-quality, durable, and functional enclosures suitable for diverse industries.