Product Description

The low noise coreless DC Motor 24V is a combination of advanced technologies designed for applications with noise sensitivity and high performance requirements. Its rated voltage of 24V provides stable and suitable power support for the equipment, showing unique advantages in many fields.

Product parameters

| Motor parameter | Motor type | |||

|---|---|---|---|---|

| name | unit | XBD28260 6045HJ- 30102 | XBD28261 2061HJ- 30102 | XBD28262 4059HJ- 30102 |

| Rated voltage | V/DC | 6 | 12 | 24 |

| Rated speed | rpm | 3827 | 5429 | 5251 |

| Rated current | A | 0.08 | 0.18 | 0.09 |

| Rated torque | mi | 0.91 | 3.04 | 3.26 |

| No-load speed | rpm | 4300 | 6100 | 5900 |

| No-load current | mA | 10 | 14 | 8 |

| Maximum efficiency | % | 76.6 | 81.6 | 80.8 |

| Rotational speed | rpm | 3827 | 5551 | 5369 |

| Electric current | A | 0.079 | 0.148 | 0.077 |

| torque | mNm | 0.9 | 2.5 | 2.7 |

| Maximum power | W | 0.9 | 4.4 | 4.6 |

| Rotational speed | rpm | 2150 | 3050 | 2950 |

| Electric current | A | 0.3 | 0.8 | 0.4 |

| torque | mNm | 4.1 | 13.8 | 14.8 |

| Locked-rotor current | A | 0.64 | 1.5 | 0.78 |

| Locked-rotor moment | mNm | 8.3 | 27.7 | 29.7 |

| Motor impedance | Ω | 9.38 | 8 | 30.77 |

| Inductive reactance of motor | mH | 0.15 | 0.43 | 1.6 |

| Torque constant | mNm/A | 13.12 | 18.61 | 38.45 |

| Speed constant | rpm/V | 716.7 | 508.3 | 245.8 |

| Revolution/torque constant | rpm/mNm | 520.4 | 220.6 | 198.8 |

| Mechanical time constant | ms | 30.65 | 19.22 | 16.39 |

| Rotor inertia | gcm2 | 5.62 | 8.32 | 7.88 |

Technological Innovation

Precision winding

The winding of the motor is carefully wound with high quality enamelled wire. This winding design ensures the stability and reliability of the motor during operation. The winding turns, wire diameter and other parameters are precisely calculated and strictly controlled, so that the motor can play the best performance under 24V voltage, output the appropriate torque and speed.

Product Display

Low noise operation

This is the outstanding highlight of the motor. By optimizing the structural design of the motor, selecting low-noise materials and advanced manufacturing technology, the noise generated by the motor during operation is minimal. Whether it is in a quiet indoor environment or in noise-demanding application scenarios, such as medical equipment, high-end office equipment, etc., it can operate quietly without causing interference to the surrounding environment.

High efficiency and energy saving

Driven by 24V voltage, the motor exhibits an efficient power conversion capability. The coreless structure reduces energy loss, allowing it to convert most of the electrical energy into mechanical energy, reducing energy consumption. This not only meets the energy-saving requirements of modern equipment, but also helps to extend the battery life of the equipment or reduce energy costs, especially for battery-powered equipment.

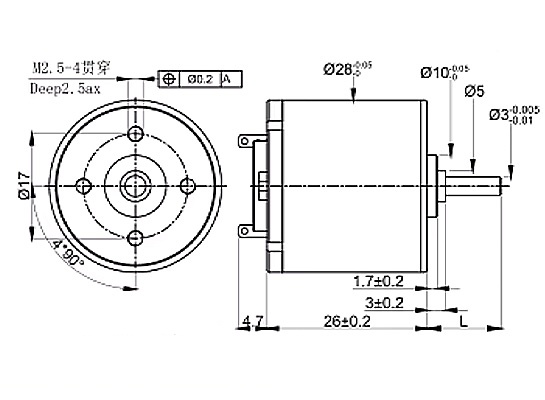

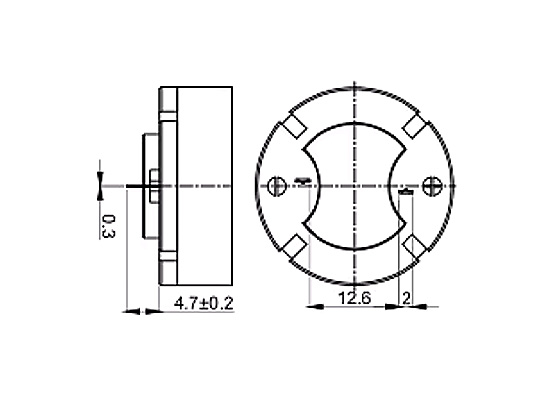

Size & Interface

Quality Control

Assembly link control: tight seam

The assembly process of the motor is like a precise jigsaw puzzle, where every component must be fitted into place without error. Our assembly workers are professionally trained, have rich experience and a high sense of responsibility. When assembling the hollow cup rotor, ensure that its position in the stator is accurate and the clearance with the brush and commutator is just right. The tightening torque of each screw is precisely calculated and strictly controlled to prevent the overall performance of the motor from being too tight or too loose. After the assembly is completed, the appearance of the motor is also carefully checked to ensure that no parts are loose, scratched or improperly assembled.

Performance testing: Comprehensive inspection

We have a set of perfect performance testing system, for each hollow cup brush motor for comprehensive and strict inspection. In terms of electrical performance detection, the starting current, no-load current, rated power, speed and torque of the motor are measured by high-precision test equipment to ensure that these parameters are within the specified tolerance range and meet the design requirements. For the mechanical properties of the motor, we simulate the actual working environment and carry out long-term operating tests to observe the vibration, noise level and heating degree of the motor. Only motors that are fully qualified in all performance indicators will be labeled as qualified in quality and enter the market.

Durability test

In order to ensure the reliability and life of the motor, we will carry out a long time durability test on the motor. In the simulation of various actual working conditions, the motor is continuously run for hundreds of hours, during which the performance indicators of the motor are continuously monitored, such as temperature changes, vibration conditions, electrical parameter stability, etc. Only motors that pass the durability test and have no significant degradation in performance will be considered qualified products.

Quality traceability system: Tracing to the source

In order to ensure the continuous stability of quality, we have established a sound quality traceability system. Each hollow cup brush motor has a unique identity, from the procurement batch of raw materials, all aspects of the production process data to the final test report, are recorded in detail. Once a quality problem is found, it can be quickly traced back to the root of the problem, and effective corrective measures can be taken to avoid the recurrence of similar problems.

Application Cases

The application of low-noise coreless DC motor in the field of prosthetics, industrial robots and service robots fully demonstrates its great potential and value in the field of robotics, and promotes the development of robot technology in the direction of more humanized, efficient and intelligent.

Cooperative partner

Service

Professional technical support team

We have a professional after-sales technical service team, the team members are experienced in the field of motor, skilled experts. They have an in-depth understanding of every technical detail of the low-noise coreless DC motor 24V, including its unique coreless structure, 24V voltage adaptation principles, winding characteristics, and key factors in low-noise design. Whether it is simple usage consultation or complex fault diagnosis, our technicians have solid expertise to quickly provide you with accurate and effective solutions.