Product Description

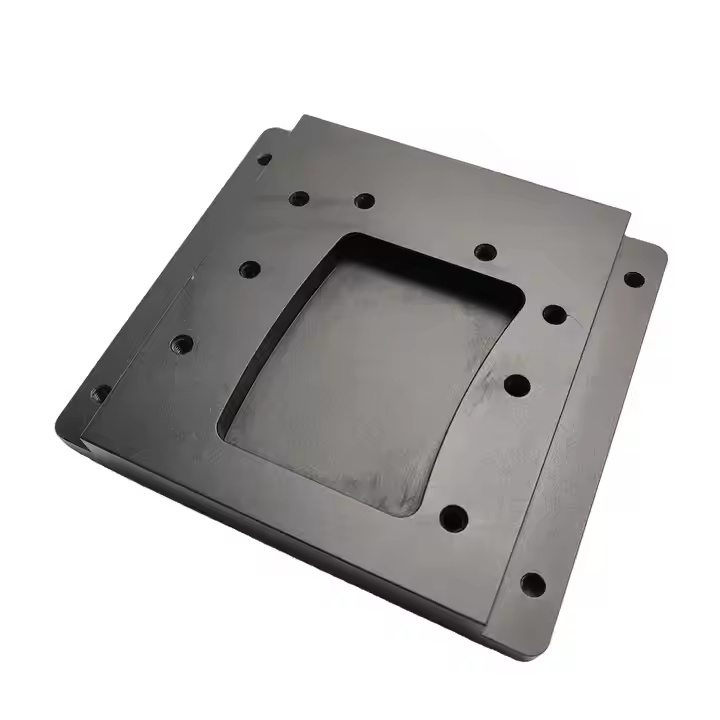

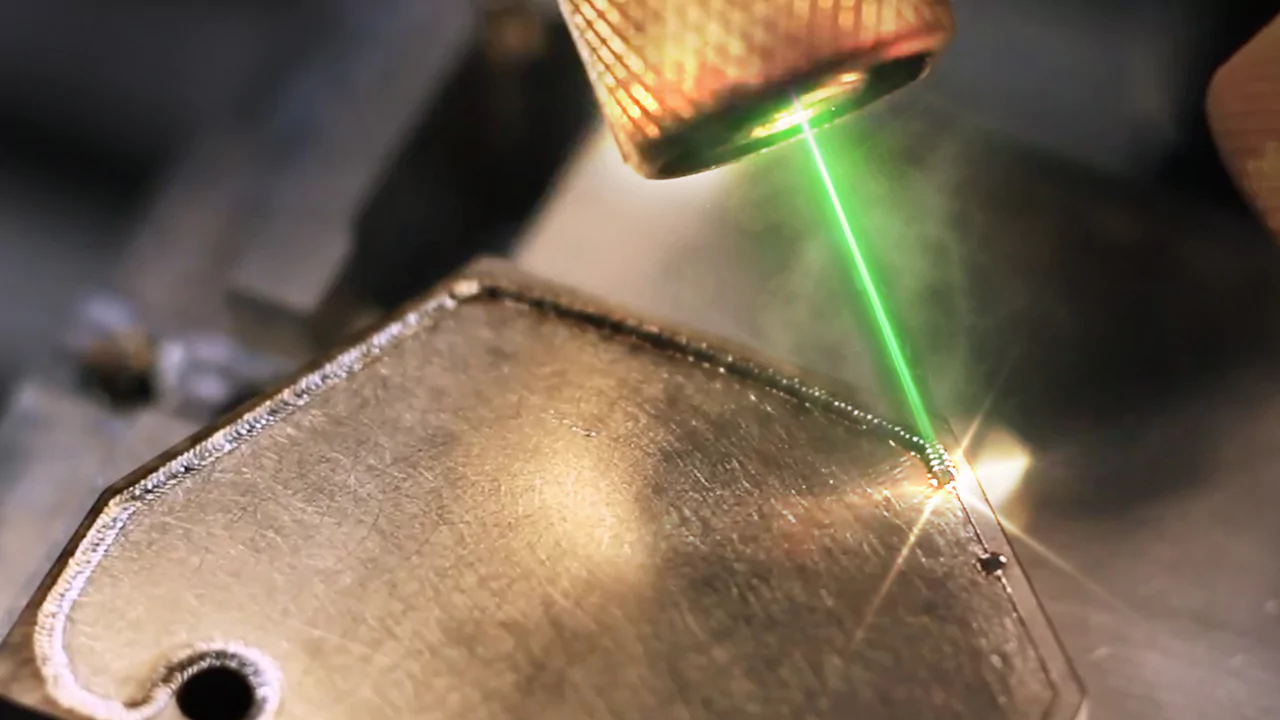

A laser welding work box is a protective enclosure used in laser welding processes to ensure safety, precision, and efficiency. It contains the laser welding equipment, shielding it from external contamination and providing a controlled environment. The box typically includes safety features such as laser protection, fume extraction, and a viewing window for operators to monitor the welding process. It helps in minimizing hazards associated with laser beams, heat, and fumes while maintaining optimal conditions for high-precision welding tasks.

Product parameters

| List | Details |

|---|---|

| Brand Name | Laser welding work box |

| Material Capabilities | Steel/Aluminum/Stainless Steel 316/etc |

| Process | Laser Cutting,Bending, Riveting , Punching |

| Thickness | 0.1-3.0mm |

| Surface treatment | Painting\Powder Coating\Plating\Polishing |

| Tolerance | 0.1mm |

| Service | Custom Fabrication Services |

| Technology | Stamping\Punching\Laser Cutting\Turning Machine |

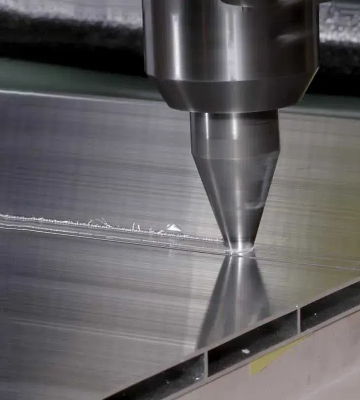

Custom Process

Design and Programming

Machine Setup

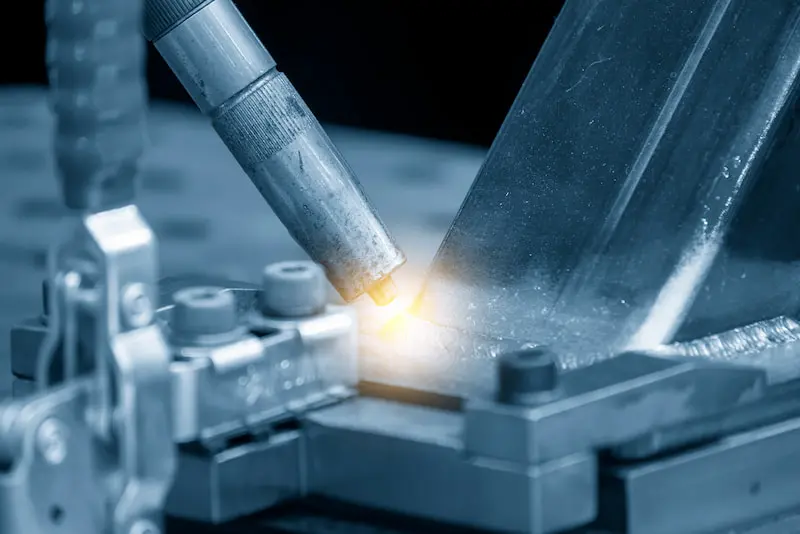

Welding Process Execution

Inspection and Finishing

Process Type

Solid State Welding

Newer Welding

Gas Welding

Material

Metal

Aluminum

Copper

Brass

Quality Control

laser welding work box ensures that the system operates safely, efficiently, and consistently. It involves checking for proper sealing to prevent laser leakage, verifying the functionality of safety features like interlocks and alarms, and ensuring the fume extraction system works effectively. Additionally, QC includes monitoring the accuracy of the laser alignment and welding parameters to ensure high-quality welds. Regular inspections for wear and tear, cleanliness, and proper calibration of equipment are also essential. Proper QC ensures the box meets industry standards and protects both the operator and the workpiece.

Processing capability

The processing capability of a laser welding work box depends on various factors, including its design, the type of laser system, and its integrated features. These work boxes typically support precise, high-speed welding of metals, ceramics, and plastics, offering fine control over weld depth and width. The laser system can be adjusted for different materials, thicknesses, and joint configurations, allowing for diverse welding applications, including micro-welding and precision parts assembly.

Additional processes

The work box is often equipped with advanced features like automated focusing, real-time process monitoring, and temperature control, ensuring consistent weld quality. It can accommodate various welding configurations, including butt joints, fillet welds, and seams. Some work boxes are designed to handle larger workpieces, while others are tailored for small, intricate components.

The fume extraction and cooling systems within the work box ensure a clean, safe, and optimal environment for the welding process. Additionally, the integration of vision systems allows for automated inspection and quality assurance. Overall, the processing capability of a laser welding work box enables efficient, high-precision welding for a wide range of industrial applications, from automotive to aerospace.

4o mini