Product Description

Wide applicable voltage range: 12 volts to 48 volts voltage range makes it have good adaptability. In different application scenarios, the power supply voltage can be selected according to the actual requirements. For example, 12 volts may be suitable for some small, low-power equipment, such as small power tools, toys, etc. The 48 volt voltage can provide power for some equipment that has high requirements for power and torque, such as electric bicycles and small electric vehicles.

Product parameters

| Motor parameter | Motor type | |||

|---|---|---|---|---|

| name | unit | XBD26541 2056HJ- 30102 | XBD26542 4056HJ- 30102 | XBD26544 8058HJ- 30102 |

| Rated voltage | V/DC | 12 | 24 | 48 |

| Rated speed | rpm | 4984 | 4984 | 5162 |

| Rated current | A | 1.39 | 0.69 | 0.48 |

| Rated torque | mi | 25.53 | 25.57 | 36.16 |

| No-load speed | rpm | 5600 | 5600 | 5800 |

| No-load current | mA | 130 | 60 | 20 |

| Maximum efficiency | % | 79.9 | 80.7 | 86.7 |

| Rotational speed | rpm | 5068 | 5096 | 5423 |

| Electric current | A | 1.22 | 0.577 | 0.292 |

| torque | mNm | 22 | 20.9 | 21.4 |

| Maximum power | W | 34 | 34.1 | 49.9 |

| Rotational speed | rpm | 2800 | 2800 | 2900 |

| Electric current | A | 5.9 | 2.9 | 2.1 |

| torque | mNm | 116 | 116.2 | 164.4 |

| Locked-rotor current | A | 11.6 | 5.8 | 4.2 |

| Locked-rotor moment | mNm | 232.1 | 232.5 | 328.8 |

| Motor impedance | Ω | 1.03 | 4.14 | 11.43 |

| Inductive reactance of motor | mH | 0.083 | 0.31 | 1.43 |

| Torque constant | mNm/A | 20.23 | 40.5 | 78.65 |

| Speed constant | rpm/V | 466.7 | 233.3 | 120.8 |

| Revolution/torque constant | rpm/mNm | 24.1 | 24.1 | 17.6 |

| Mechanical time constant | ms | 3.34 | 3.45 | 2.56 |

| Rotor inertia | gcm2 | 13.22 | 13.69 | 5.13 |

Technological Innovation

Performance at different voltages

At lower voltages (such as 12 volts), the output power of the motor is relatively small and the speed may be low, but it usually has lower energy consumption and better safety; At higher voltages (such as 48 volts), the motor is able to provide greater output power and torque, and the speed may be higher, but the requirements on the circuit system are also higher, such as the need for better insulation and overcurrent protection measures.

Product Display

Good speed control performance

Dc motor has good speed regulation performance, which can adjust the speed of the motor by changing voltage, current or excitation. For XBD-2654 motors, in the voltage range of 12 volts to 48 volts, different speed requirements can be achieved by adjusting the voltage to meet the requirements of various application scenarios.

High starting torque

The ability of a DC motor to produce a large amount of torque when starting up gives it an advantage in situations where a fast start and large loads need to be overcome, such as in the start-up phase of an electric vehicle or in equipment where heavy lifting is required.

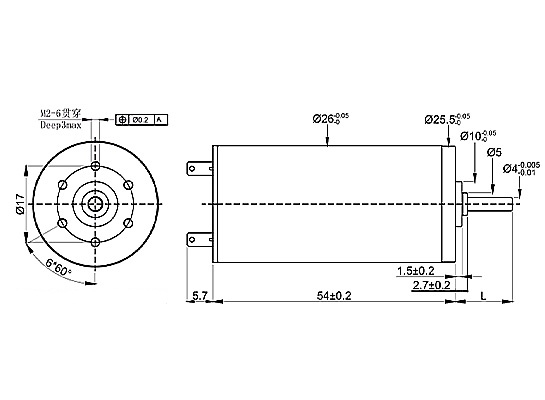

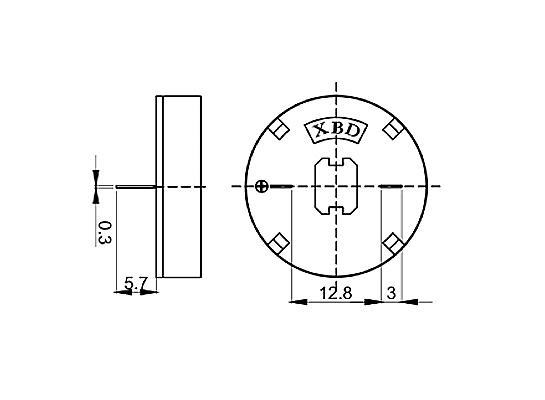

Size & Interface

Quality Control

Assembly link control: tight seam

The assembly process of the motor is like a precise jigsaw puzzle, where every component must be fitted into place without error. Our assembly workers are professionally trained, have rich experience and a high sense of responsibility. When assembling the hollow cup rotor, ensure that its position in the stator is accurate and the clearance with the brush and commutator is just right. The tightening torque of each screw is precisely calculated and strictly controlled to prevent the overall performance of the motor from being too tight or too loose. After the assembly is completed, the appearance of the motor is also carefully checked to ensure that no parts are loose, scratched or improperly assembled.

Performance testing: Comprehensive inspection

We have a set of perfect performance testing system, for each hollow cup brush motor for comprehensive and strict inspection. In terms of electrical performance detection, the starting current, no-load current, rated power, speed and torque of the motor are measured by high-precision test equipment to ensure that these parameters are within the specified tolerance range and meet the design requirements. For the mechanical properties of the motor, we simulate the actual working environment and carry out long-term operating tests to observe the vibration, noise level and heating degree of the motor. Only motors that are fully qualified in all performance indicators will be labeled as qualified in quality and enter the market.

Durability test

In order to ensure the reliability and life of the motor, we will carry out a long time durability test on the motor. In the simulation of various actual working conditions, the motor is continuously run for hundreds of hours, during which the performance indicators of the motor are continuously monitored, such as temperature changes, vibration conditions, electrical parameter stability, etc. Only motors that pass the durability test and have no significant degradation in performance will be considered qualified products.

Quality traceability system: Tracing to the source

In order to ensure the continuous stability of quality, we have established a sound quality traceability system. Each hollow cup brush motor has a unique identity, from the procurement batch of raw materials, all aspects of the production process data to the final test report, are recorded in detail. Once a quality problem is found, it can be quickly traced back to the root of the problem, and effective corrective measures can be taken to avoid the recurrence of similar problems.

Application Cases

XBD-2654 12V-48V electric DC motor, is the smart home quality power choice. In the sweeping machine, it has flexible speed regulation, efficient cleaning and low noise; For smart curtains, can accurately control the opening and closing speed, easy to pull heavy curtains; In the smart door lock, it can quickly and accurately respond to unlocking instructions to ensure safety; Installed in a smart electric sofa, it can adjust the Angle smoothly to bring you a comfortable experience.

Cooperative partner

Service

We offer a full range of services for XBD-2654 electric DC motors. Before sales, the professional team will explain its advantages in smart home applications such as sweepers, smart curtains, smart door locks, and smart electric sofas in detail to help you select accurately. After sale, the transportation packaging is safe and reliable to ensure that the motor is delivered in good condition. There are clear guidelines for installation, and engineers are ready to respond in case of problems.