Product Description

Compact appearance and size advantage

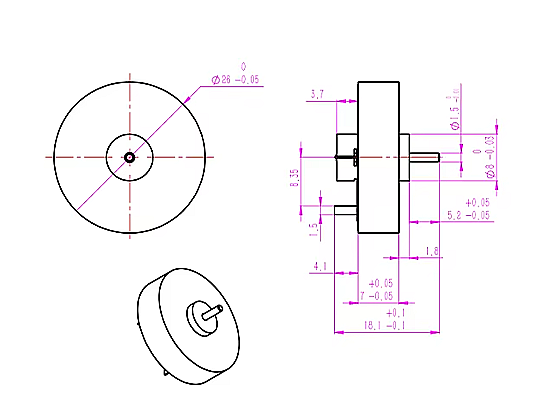

This is a compact DC coreless motor with a diameter of only 26mm and a length of 7mm, which is an exquisite work in the field of micro motors. Its compact size provides the ideal power solution for a variety of space-demanding application scenarios. Whether it is a small internal space of the device, or a portable product with strict limits on the overall volume and weight, it can be easily adapted and perfectly embedded, creating favorable conditions for the miniaturization design of the device.

Product specifications

| name | argument | name | argument |

|---|---|---|---|

| diameter | 26mm | Locked-rotor moment | 12.4mNm |

| Length | 7mm | Maximum output power | 5W |

| voltage | 12V | Rated current | 0.19A |

| Rotational speed | 12000rpm | Maximum efficiency | 78.90% |

Product parameters

| Motor parameter | Motor type | |

|---|---|---|

| name | unit | XBD2607 |

| Rated voltage | V/DC | 12 |

| Rated speed | rpm | 12888 |

| Rated current | A | 0.19 |

| Rated torque | mi | 1.3 |

| No-load speed | rpm | 14400 |

| No-load current | mA | 20 |

| Maximum efficiency | % | 78.9 |

| Rotational speed | rpm | 13320 |

| Electric current | A | 0.139 |

| torque | mNm | 0.9 |

| Maximum power | W | 4.7 |

| Rotational speed | rpm | 7200 |

| Electric current | A | 0.8 |

| torque | mNm | 6.2 |

| Locked-rotor current | A | 1.6 |

| Locked-rotor moment | mNm | 12.4 |

| Motor impedance | Ω | 7.5 |

Technological Innovation

Efficiency and energy saving advantages

Because the coreless design reduces energy loss, the motor's operating efficiency is significantly improved. Compared with the traditional core motor, under the same input power, this coreless motor can convert more electrical energy into mechanical energy, effectively reducing energy consumption. This is not only conducive to the energy-saving operation of the equipment, extend the battery life of the equipment (for battery powered equipment), but also reduce the heat phenomenon of the motor during operation, and further improve the reliability and service life of the motor.

Product Display

Voltage adaptability and stability

The operating voltage is 12V, which is a standard voltage widely used in many small electronic devices. This voltage versatility allows the motor to be easily integrated with a variety of 12V power systems, both battery-powered and externally regulated, ensuring stable and reliable operation of the motor. In different power supply environments, the performance of the motor fluctuates very little and can consistently output power.

Speed and torque characteristics

Despite the small size of the motor, it has excellent performance in terms of speed and torque. It can meet the needs of a variety of applications, in the need for fast action in the scene, such as small cooling fans, micro vibrators, can quickly rotate, to achieve efficient air flow or vibration effect. At the same time, the torque output is also enough to drive the corresponding load, to ensure that when driving small mechanical structures or transmission components, the motor can operate stably, without stalling or insufficient power.

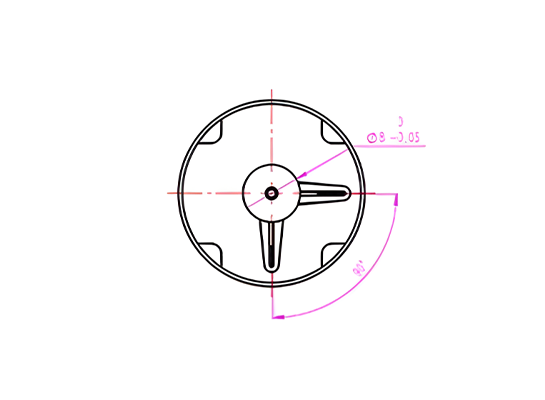

Size & Interface

Quality Control

Assembly link control: tight seam

The assembly process of the motor is like a precise jigsaw puzzle, where every component must be fitted into place without error. Our assembly workers are professionally trained, have rich experience and a high sense of responsibility. When assembling the hollow cup rotor, ensure that its position in the stator is accurate and the clearance with the brush and commutator is just right. The tightening torque of each screw is precisely calculated and strictly controlled to prevent the overall performance of the motor from being too tight or too loose. After the assembly is completed, the appearance of the motor is also carefully checked to ensure that no parts are loose, scratched or improperly assembled.

Performance testing: Comprehensive inspection

We have a set of perfect performance testing system, for each hollow cup brush motor for comprehensive and strict inspection. In terms of electrical performance detection, the starting current, no-load current, rated power, speed and torque of the motor are measured by high-precision test equipment to ensure that these parameters are within the specified tolerance range and meet the design requirements. For the mechanical properties of the motor, we simulate the actual working environment and carry out long-term operating tests to observe the vibration, noise level and heating degree of the motor. Only motors that are fully qualified in all performance indicators will be labeled as qualified in quality and enter the market.

Durability test

In order to ensure the reliability and life of the motor, we will carry out a long time durability test on the motor. In the simulation of various actual working conditions, the motor is continuously run for hundreds of hours, during which the performance indicators of the motor are continuously monitored, such as temperature changes, vibration conditions, electrical parameter stability, etc. Only motors that pass the durability test and have no significant degradation in performance will be considered qualified products.

Quality traceability system: Tracing to the source

In order to ensure the continuous stability of quality, we have established a sound quality traceability system. Each hollow cup brush motor has a unique identity, from the procurement batch of raw materials, all aspects of the production process data to the final test report, are recorded in detail. Once a quality problem is found, it can be quickly traced back to the root of the problem, and effective corrective measures can be taken to avoid the recurrence of similar problems.

Application Cases

Automation and robotics

In the design of micro-automated production lines and small robots, the motor is an indispensable power element. In the micro-assembly robot, the motor can drive the tiny movements of the arm joints to achieve fine parts assembly. In the small inspection robot, it is used to drive the rotation or movement of the sensor module to ensure the comprehensive detection of the environment. Its compact structure and good performance provide strong support for the miniaturization and high performance of automation and robotic equipment.

Smart home field

It also has important applications in smart home devices. For example, in the internal transmission mechanism of the intelligent door lock, the motor provides power for the expansion and expansion of the lock tongue to ensure the normal switch of the door lock; In the track drive system of the small intelligent curtain, the curtain can be pulled smoothly to realize the automatic opening and closing of the curtain. The low power consumption of the motor contributes to the long-term stable operation of smart home devices and reduces energy consumption.

Cooperative partner

Service

Professional installation guide

After purchasing our motor, we provide you with detailed and professional installation instructions. For this micro motor, we will provide you with a variety of installation guides including written instructions, clear illustrations and video tutorials. If you encounter any difficulties in the installation process, our technical support team can provide you with remote guidance through telephone, online customer service, etc., to ensure that you can smoothly install the motor into your equipment, ensure the correctness and stability of the installation, and avoid the impact of improper installation on the performance of the motor.