Product Description

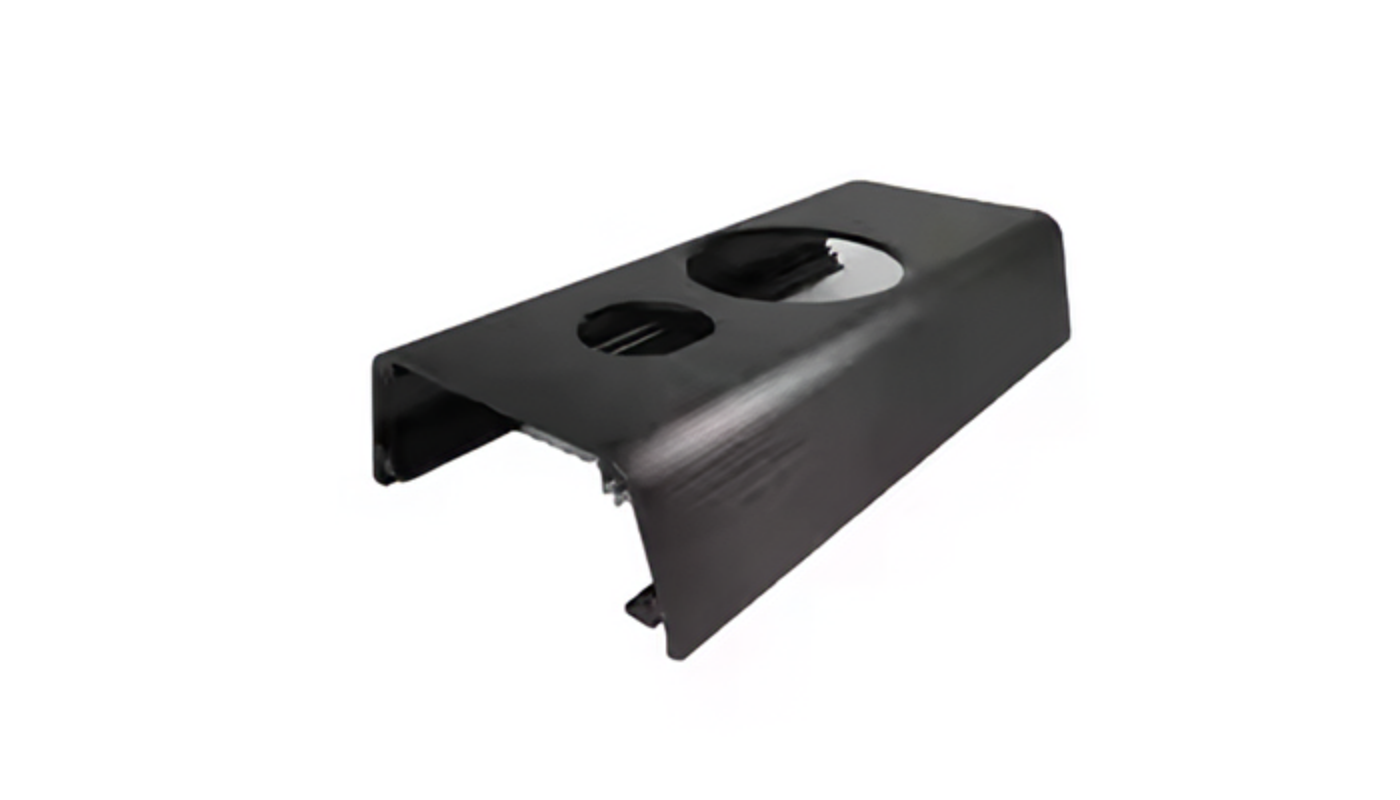

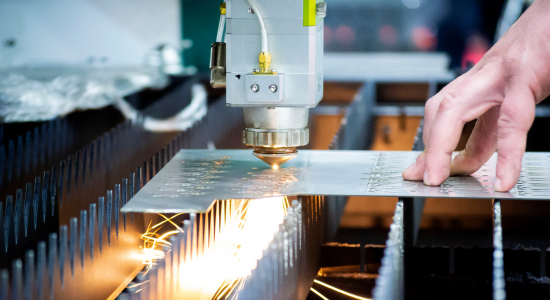

CNC milling hard anodizing aluminum alloy parts are precision-machined components made from high-strength aluminum alloy, featuring a durable, corrosion-resistant hard anodized surface for enhanced performance and longevity in demanding applications.

Product parameters

| Product | Customized Hard Anodized Aluminum Part |

| Material | Aluminum, steel, brass etc |

| Thickness | 0.4mm-500mm |

| Size | Customized |

| Tolerance | +/-0.1mm even 0.01mm |

| Finishing | Anodized, powder coated, brushed, polished, wood grain, electrophoresis etc |

| Range | Electronic automotive communication etc |

| Sample | Free |

| MOQ | As per customer's request |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

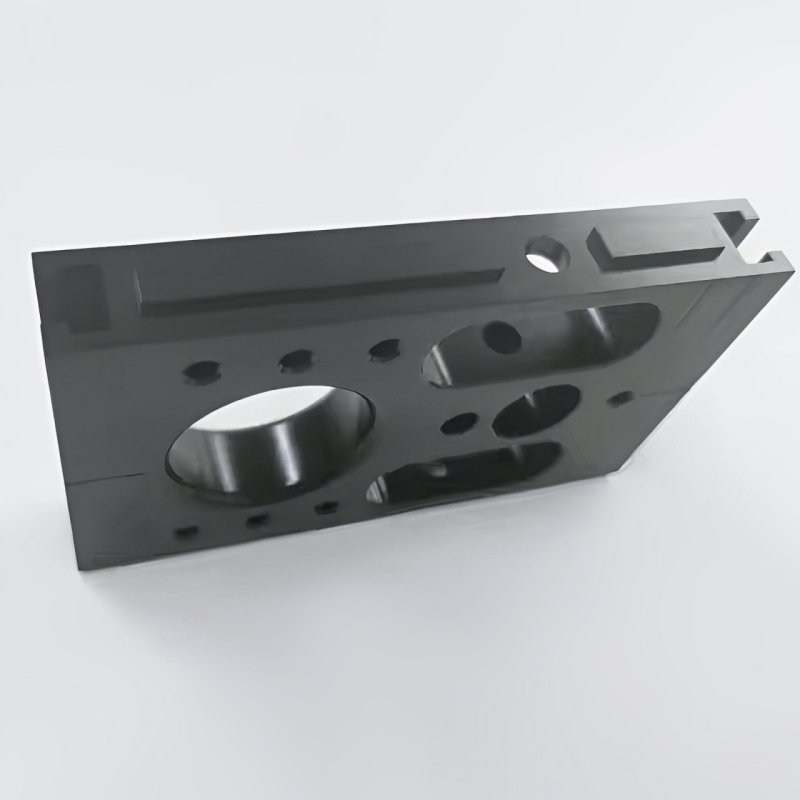

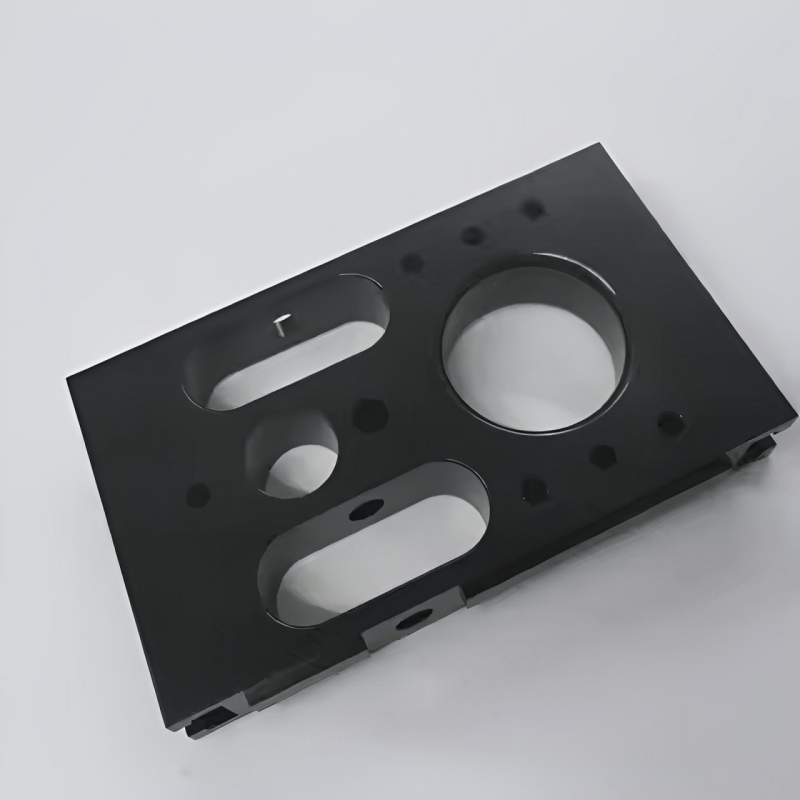

Mobile Robot Frame Component

Reason:

This part can serve as the base or structural plate of a robot. The various holes allow for the installation of wheels, drive systems, or sensor mounts.

CNC Support Plate

Reason:

The holes and openings are designed to support the installation of cutting heads or drilling heads. Additionally, they facilitate the mounting or alignment of cutting tools.

Rotary Axis Plate

Reason:

This part can be used as a base for the rotary axis of CNC machines or robots. The holes allow for the installation of moving components, such as bearings or rotary motors.

Material

Aluminum Alloy

Stainless Steel

Quality Control

Quality control for CNC milling hard anodizing aluminum alloy parts ensures precision and durability through dimensional checks, surface finish inspections, and testing of the anodized layer for thickness, uniformity, and color consistency. Final checks confirm functionality and compliance with industry standards.

Processing capability

The processing capability of CNC milling hard anodizing aluminum alloy parts includes precise machining of complex geometries with tight tolerances. CNC milling allows for high accuracy in cutting, drilling, and shaping aluminum alloy components. The subsequent hard anodizing process enhances surface hardness, wear resistance, and corrosion resistance, making the parts suitable for demanding applications. The combination of CNC milling and hard anodizing ensures the production of durable, high-performance components that meet both dimensional and functional requirements.

Additional processes

Additional processes for CNC milling hard anodizing aluminum alloy parts may include surface polishing, deburring, and passivation to improve the surface quality and finish. After anodizing, parts can undergo laser engraving or marking for identification or branding. For enhanced performance, processes such as heat treatment or assembly with other components may also be carried out to ensure the parts meet specific functional and aesthetic requirements. These additional steps ensure the final product is both durable and precise, ready for its intended application.