Product Description

Top-tier aluminum CNC machining parts expertly designed for mass production, providing extraordinary precision, exceptional durability, and unwavering reliability to cater to the sophisticated requirements of modern industries, advanced manufacturing, and complex engineering applications with maximum efficiency.

Product parameters

CNC Turning | |

Our CNC turning and milling services can produce highly accurate and complex parts from a variety of materials, including metals,plastics,and composites. | |

Samples | 1~3 Day |

Machinery Axis | 3,4,5,6 |

Surface Roughness | Ra 0.1~3.2 |

Lead time | 7~14 Day |

Supply Ability | 300,000Piece/Month |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

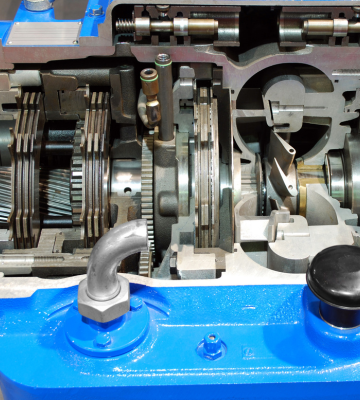

Industrial Machine Parts

Reason:

These parts are strong and durable for use in industrial machinery, such as spindles, cranks, or machine bases. Aluminum's lightweight and wear-resistant properties make it ideal for these applications.

Transmission Components

Reason:

These parts can be used in transmission systems, such as bearings, drive chains, or gear assemblies, as they are resistant to pressure and impact, ensuring smooth operation and efficiency.

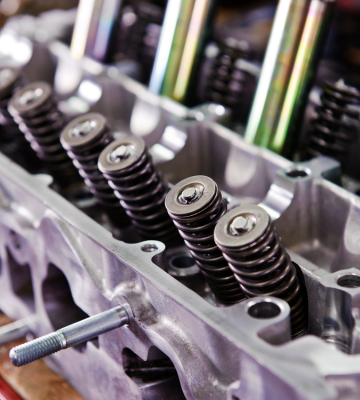

Manufacturing Tools Parts

Reason:

The parts shown in the images are suitable for use in tools required for manufacturing or machines that need high precision, such as tools used for turning or milling workpieces in production processes

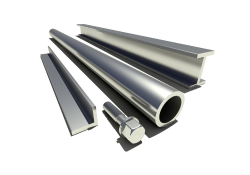

Material

Aluminum Alloy

Stainless Steel

Quality Control

Quality control for machining aluminum mass production CNC parts ensures high precision and consistency across all components. Each part undergoes rigorous inspection, including dimensional checks, surface finish analysis, and tolerance measurements, using advanced equipment to meet strict industry standards. The process also includes thorough testing for durability and performance, ensuring that every part functions efficiently in its intended application. By maintaining strict quality assurance protocols, we guarantee reliable and top-quality products for a wide range of industrial uses.

Processing capability

Our machining capability for aluminum mass production CNC parts includes advanced machining techniques that deliver high precision and efficiency. With state-of-the-art CNC machines, we can produce complex shapes and components with tight tolerances, ensuring consistency in large-scale production. Our skilled team utilizes automated processes for faster turnaround times while maintaining superior quality. Whether for small or large batch production, we can handle a variety of aluminum alloys to meet the diverse needs of industrial applications, providing reliable and cost-effective solutions.

Additional processes

In addition to CNC machining, we offer a range of additional processes for aluminum mass production parts, including surface treatments like anodizing, powder coating, and polishing to enhance durability, appearance, and corrosion resistance. We also provide assembly services, allowing for the integration of multiple components into finished products. These additional processes ensure that the parts meet specific functional and aesthetic requirements, offering comprehensive solutions for a variety of industrial applications.