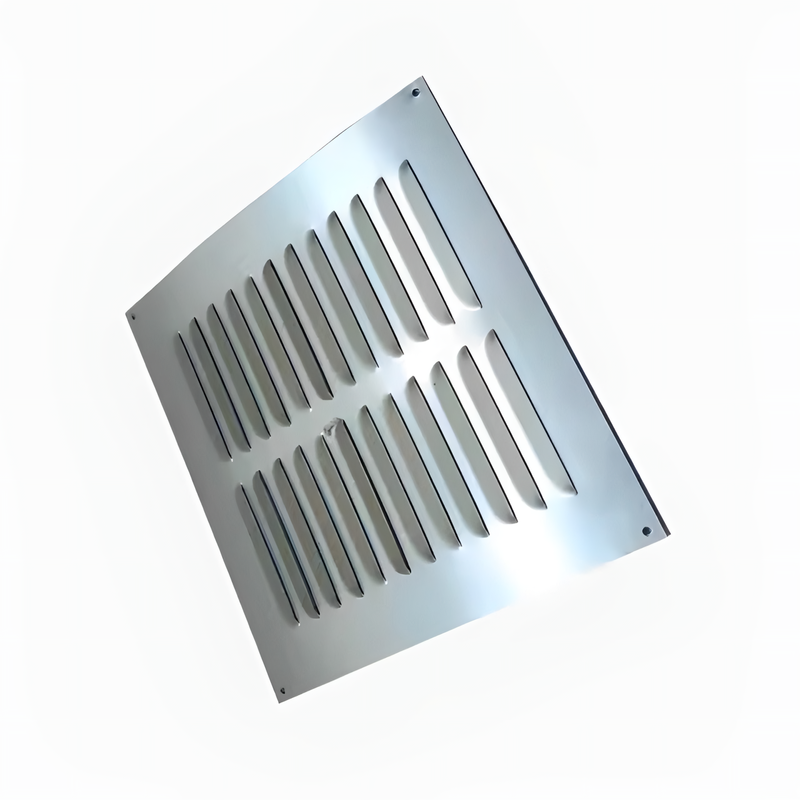

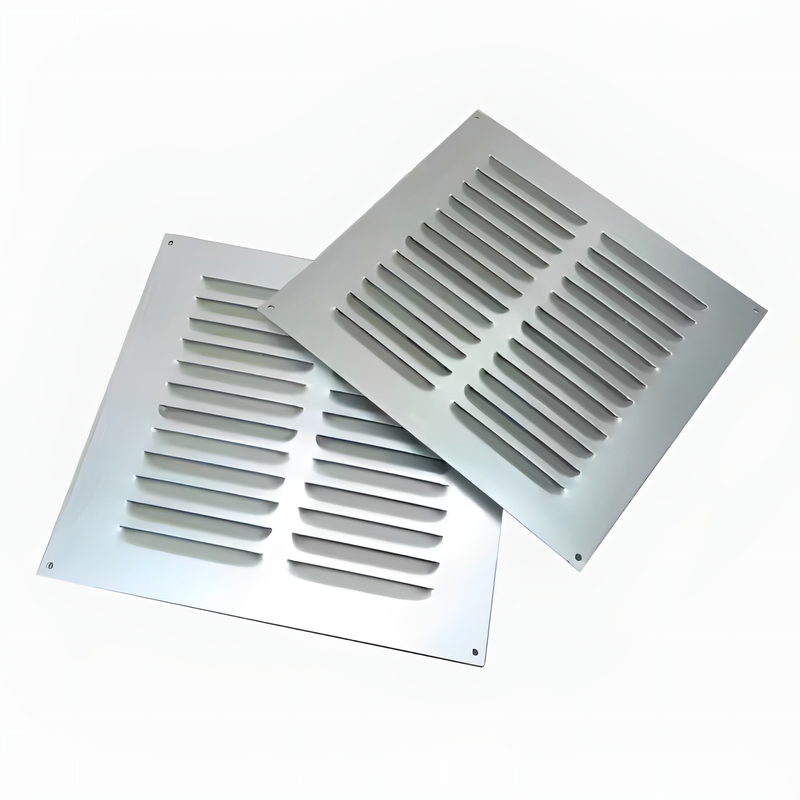

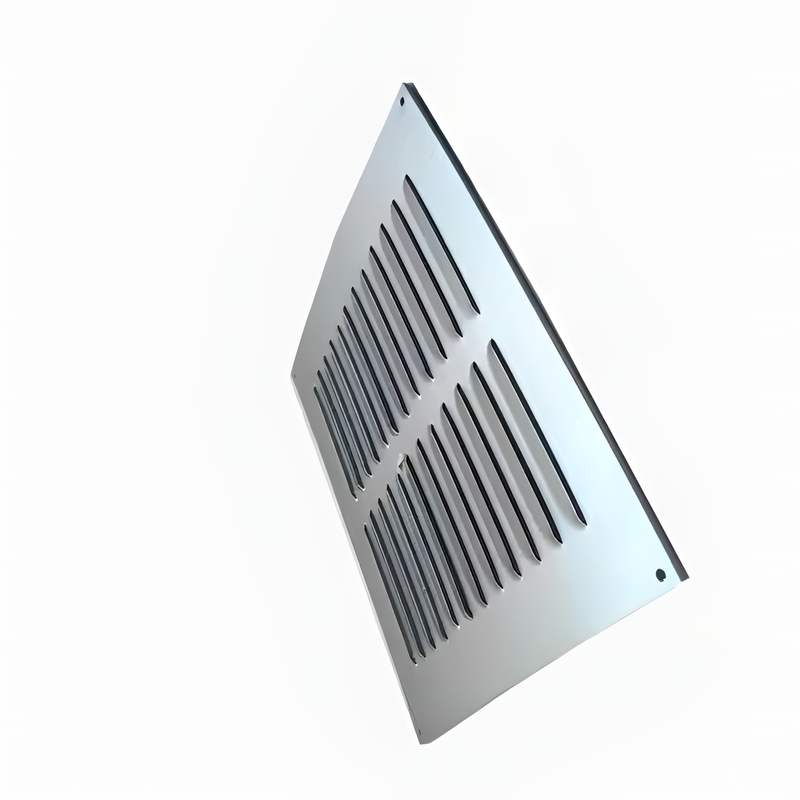

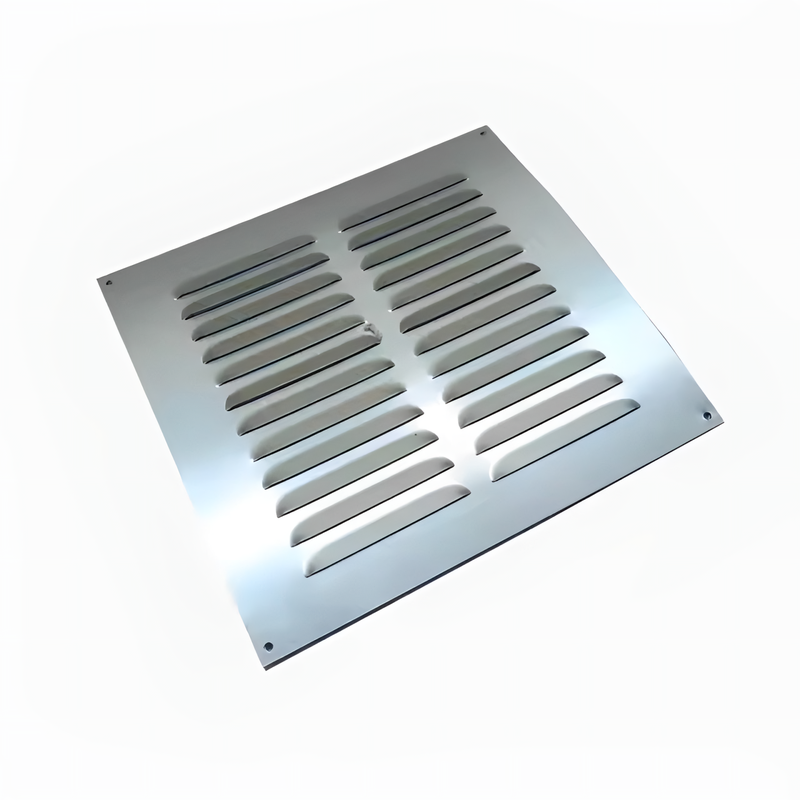

Product Description

Sheet Metal Machining Services provide precise cutting, bending, and shaping of sheet metal using advanced techniques like CNC punching, laser cutting, and bending. These services cater to industries such as automotive, aerospace, and electronics, ensuring high accuracy and durability for custom parts or mass production. They offer cost-effective solutions with the flexibility to handle a wide range of materials, from aluminum to stainless steel, ensuring quality and performance for various applications.

Product parameters

| CNC Machining or Not: | Cnc Machining | Color: | Customized Color |

| Type: | Broaching, DRILLING, Laser Machining, Turning,.. | Material Capabilities: | Aluminum, Brass, Bronze, Copper, Hardened Metals, Iron,Alloy steel |

| Item: | CNC Presicion Machining | Surface treatment | treatment Oxidation, Polishing, zinc plating.. |

| Service: | Customized OEM | Product name: | Machining Parts |

| Delivery Time: | 5-10 days ODM High | MOQ: | 1 piece |

| Drawing Format: | 2D/(PDF/CAD)3D(IGES/STEP | Shape: | According to Drawing of Customer |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Metal Racks and Shelving Units

Used in warehouses, factories, or retail stores, these are made using CNC punching and bending to form metal racks. The punching process creates holes for adjustable shelves, and bending gives the racks the necessary structure to support heavy loads.

Cooling Plates for Industrial Machines

These plates are made using CNC cutting and bending to ensure proper heat dissipation in machinery. Cooling plates are designed with precise cut-outs for pipes and ventilation systems, providing efficient heat management to prevent overheating in heavy machinery.

Lighting Fixtures

Sheet metal machining is used to create parts for lighting fixtures like lamp holders, light reflectors, and housing for LED lights. Laser cutting helps form intricate designs, while bending is used to create the shape of the fixture, ensuring durability and proper lighting distribution.

Material

Aluminum Alloy

Stainless Steel

Quality Control

Quality control in sheet metal machining services ensures each part meets precise specifications through thorough inspection and testing. Using advanced tools like CMM and laser measurement, parts are checked for dimensional accuracy, surface finish, and material integrity. Any deviations from the design are promptly corrected, ensuring consistent, high-quality results for various industrial applications.

Processing capability

The processing capability of sheet metal machining services includes advanced techniques such as CNC punching, laser cutting, and CNC bending to produce precise and complex parts. These services handle various materials like aluminum, stainless steel, and copper, offering custom solutions with tight tolerances. Surface treatments like coating and anodizing further enhance durability and aesthetics, ensuring high-quality components for industries like automotive, aerospace, and electronics.

Additional processes

Additional processes in sheet metal machining services include surface treatments such as powder coating, anodizing, and galvanizing to enhance corrosion resistance, durability, and appearance. Welding, riveting, and bending are also commonly used to assemble complex parts or create specific shapes. These additional processes ensure that the final product meets both functional and aesthetic requirements, providing reliable, long-lasting components for industries like automotive, electronics, and construction. Additionally, parts may undergo quality finishing processes like deburring, polishing, and laser engraving to ensure smooth surfaces and precise markings.